A casting method for thin-walled castings

A technology of thin-walled castings and molten iron, applied in the field of casting castings, can solve the problems of insignificant difference effect, increase production cost, prolong production cycle, etc., reduce production cost, prevent the infiltration of oxygen and nitrogen, and solve the phenomenon of hard material Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

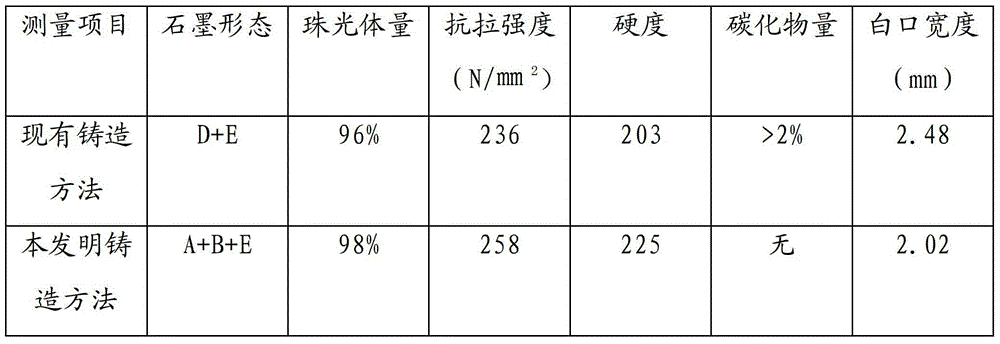

[0018] Utilize casting method of the present invention and existing casting method to cast a long 80mm respectively, diameter 10mm, the cylindrical test block that thickness is 6mm, measure respectively the graphite form, pearlite amount, Tensile strength, hardness, amount of carbide, width of white hole, the results are shown in the table below:

[0019]

[0020] It can be seen from the above table that the test block cast by the casting method of the present invention has a small white mouth width, significantly improved tensile strength and hardness, no carbides, and no local material hardening phenomenon, which ensures the consistency of the performance of different parts of the casting .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com