Combined ice-breaking equipment and method of notching and hull pressure

A kind of ice-breaking equipment and groove cutting technology, applied in the direction of ice-breaking ships, etc., can solve the problems of unfavorable ship advance, limited lateral width of ice-breaking area, limited ice-breaking ability of ice-breaking ships, etc., and achieve the effect of improving ice-breaking ability and continuous ice-breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

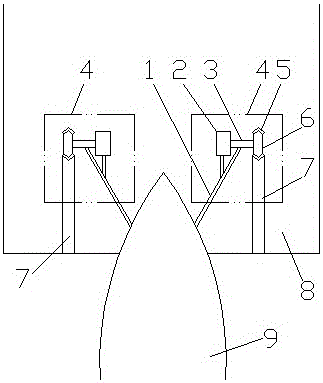

[0014] Depend on figure 1 The combined ice-breaking equipment for slotting and hull pressure shown is a combined ice-breaking equipment for slotting and hull pressure. 9 are set symmetrically on both sides.

[0015] The ice breaking device 4 includes an outrigger 1, a milling cutter provided on the outrigger 1, and a power unit connected with the milling cutter on the outrigger 1, and the rear end of the outrigger 1 is connected to the hull 9 of the icebreaker 1. The front end extends to the front of the hull 9 outside, and the milling cutter and the power unit driving the milling cutter to rotate are all arranged on the front end of the outrigger 1 . The milling cutter is arranged horizontally, and the axial direction of the milling cutter is the width direction of the icebreaker, that is, the central axis of the milling cutter extends along the width direction of the icebreaker hull 9 . The milling cutter comprises a cutter bar 3 and a cutter head arranged on the cutter ba...

Embodiment 2

[0018] Depend on figure 1 The combined icebreaking method of grooving and hull pressure shown is realized on the basis of Example 1. First, the combined icebreaking equipment of grooving and hull pressure described in Example 1 is prepared, and the icebreaker travels on the frozen river surface When the power unit drives the milling cutter to rotate, before the icebreaker travels to the ice surface 8, the two milling cutters of the two icebreaking devices 4 mill out two cutting grooves 7 on the ice surface 8 on both sides in front of the icebreaker hull 9, and the icebreaker hull 9 travels During the process, it is pressed on the ice surface 8 between the two cutting grooves 7, and the cutting groove 7 and the icebreaker apply pressure to jointly break the ice.

[0019] The combined ice-breaking method of grooving and pressure application cuts the ice sheet by grooving, resulting in changes in the stress on the cross-section at the grooving place. The stress in the middle of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com