Column piles and high-voltage wire tower substrate utilizing column piles

A technology for wire towers and piles, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as low efficiency, environmental pollution, waste of resources, etc., and achieve simple overall structure, low manufacturing cost, and enhanced stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

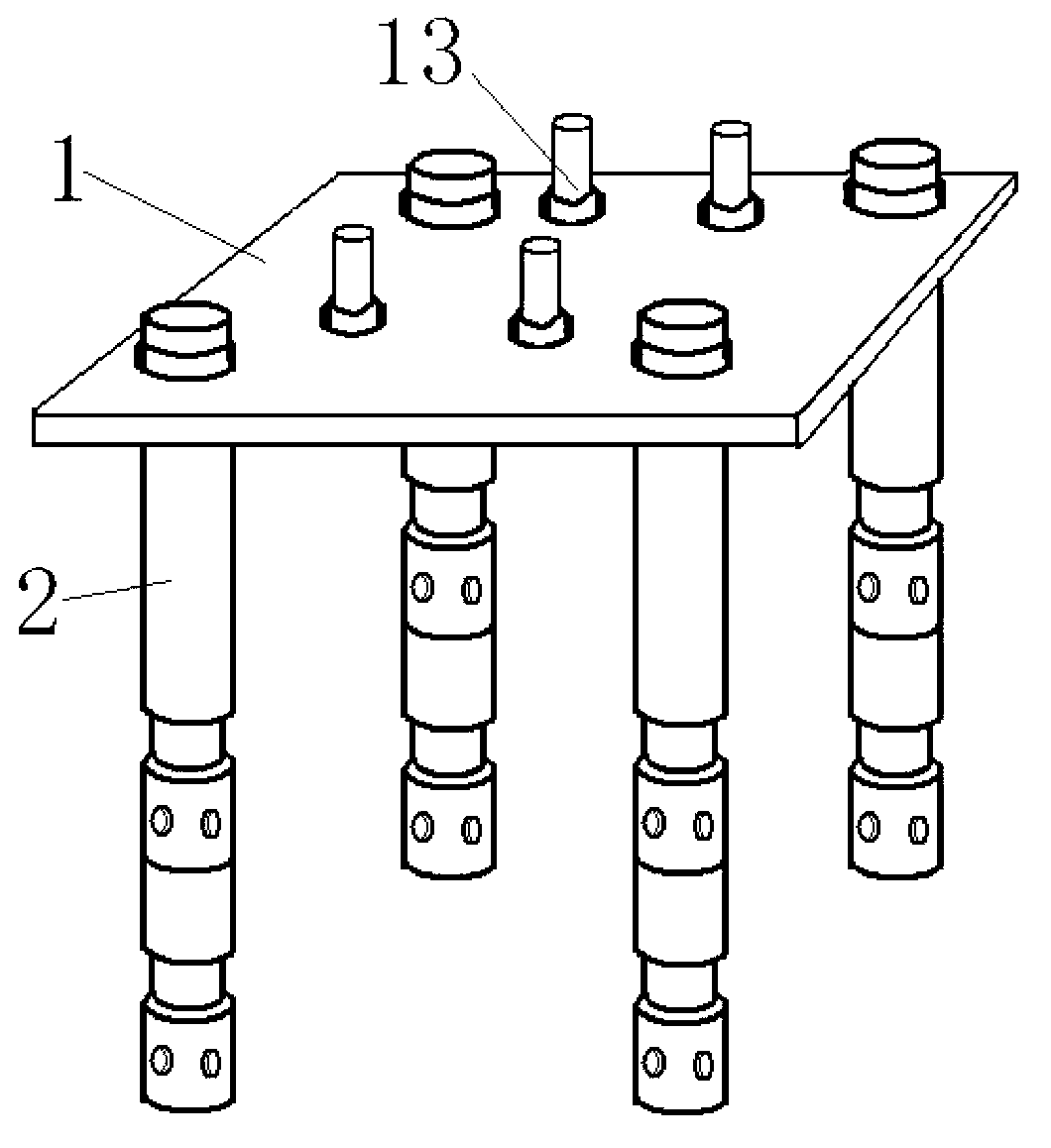

[0026] Such as figure 1 Shown is a high-voltage electric tower base of the present invention, which includes a connecting plate 1 for connecting with the main body of the high-voltage electric tower and a base excavated vertically installed on the connecting plate 1 for inserting into the rocky surface A plurality of piles in the installation holes are fixedly connected to the connecting plate 1 at the top, and the piles form a stable support part at the lower part of the base.

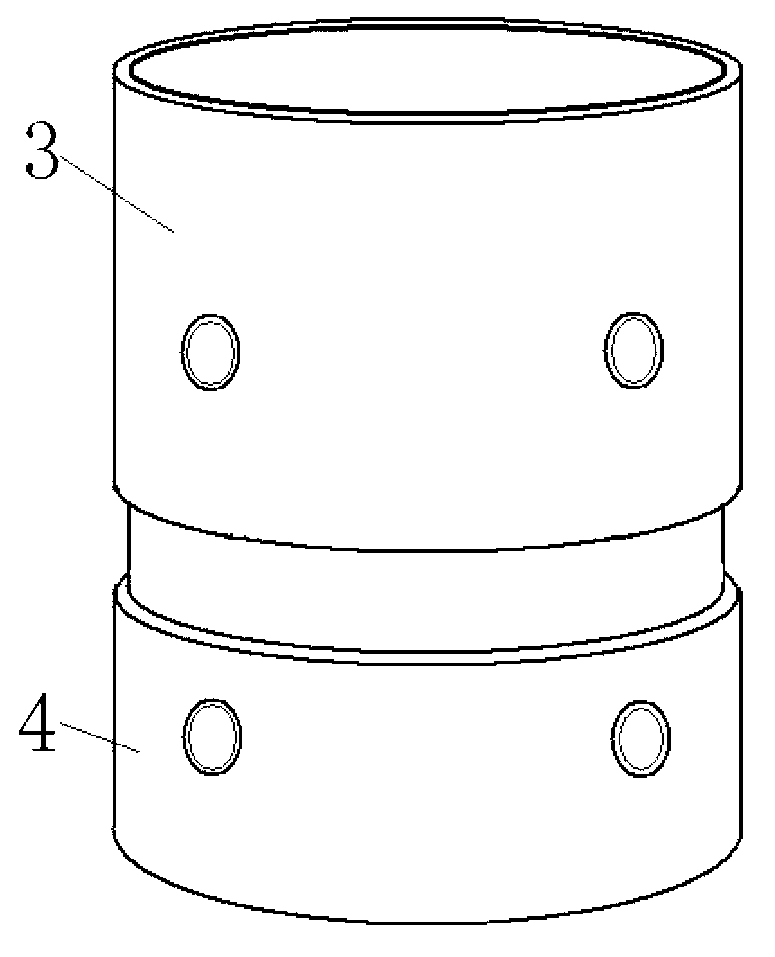

[0027] Such as figure 2 As shown, the main body of the column pile is a pillar 2 for inserting into the base mounting hole excavated on the surface of the rock, and a pillar 2 is provided inside the pillar 2 to protrude toward the outside of the pillar under the gravity of the main body of the high-voltage electric tower. and can be against the base stabilizing reinforcement device on the wall of the mounting hole outside the pillar 2, and the base stabilizing reinforcement device will automatically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com