LED lens set with firm structure and good durability and lighting device

A technology of LED lens and lens, applied in the field of lighting, can solve the problems of easy interruption, aging cracking, buckle fracture, etc., and achieve the effect of increasing the firmness and enhancing the firmness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

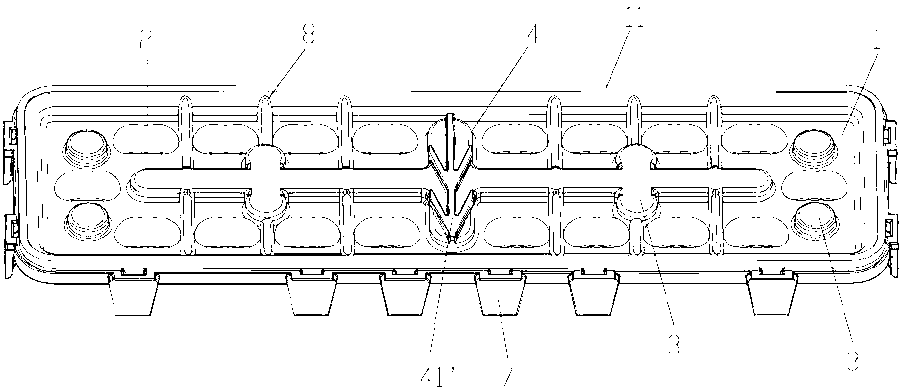

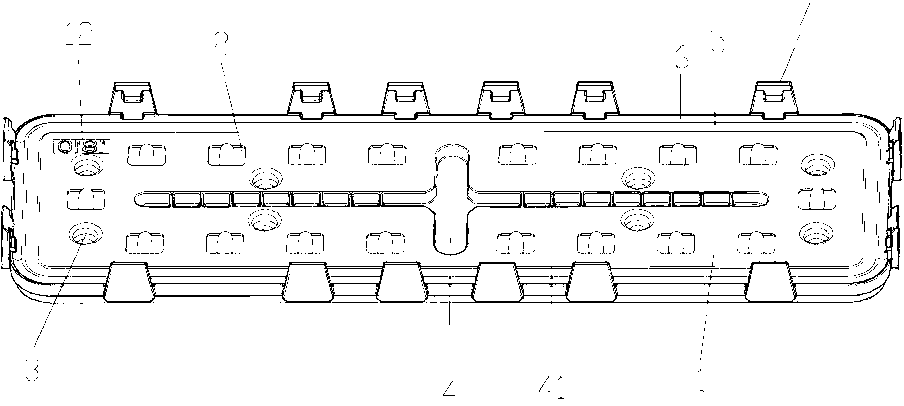

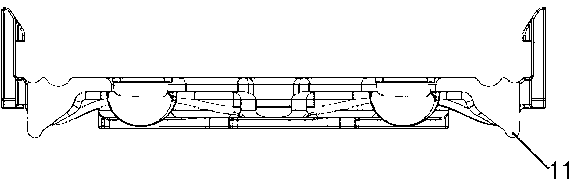

[0053] see Figure 1A , Figure 1B and figure 2 , the LED lens group provided by this embodiment includes a lens base 1, and a plurality of lenses 2 arranged on the lens base 1, a screw accommodation groove 3, a cross-shaped wire-avoiding groove 4 for accommodating electric wires, a solid The silicone ring groove 5 and the liquid silicone ring groove 6, the liquid silicone ring groove 6 is arranged on the edge of the lens base 1, the solid silicone ring groove 5 is arranged on the inner side of the liquid silicone ring groove 6, and is also included in the lens base A plurality of buckles 7 around the seat 1, the LED lens group is connected with the heat sink of the LED lighting device through these buckles 7. Wherein, according to the current commonly used design, the cross-shaped wire-avoiding groove 4 and the screw accommodating groove 3 protrude outward relative to the plane of the lens base 1 .

[0054] Wherein, the periphery of the lens base 1 adopts a thickened desig...

Embodiment 2

[0068] see Figure 5 , the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the light distribution direction indicator arrow 41' arranged on the cross-shaped wire-avoiding groove 4 is slightly smaller, and does not fill the entire cross-shaped wire-avoiding groove 4 The short side; and, the arrangement of the buckles 7 is relatively uniform: two buckles 7 are arranged in the middle of the long side of the lens base.

[0069]

Embodiment 3

[0071] see Figure 6 , this embodiment provides another LED lens group with a strengthening mechanism, wherein, its difference from Embodiment 2 lies in the following points:

[0072] The arrangement of the lenses 2 is different. In this embodiment, the total number of lenses is the same as in Embodiment 1, but the lenses 2 are arranged in two rows, and the electric wire accommodating groove 4' is a strip groove, and the light distribution direction indicator arrow 41 on it '' corresponds to its size; and is located in the middle of a row of lenses. This setting can greatly reduce the width of the lens group and the LED module, thereby saving materials; because the circuit board is narrowed, only two screws are needed for fastening, so this embodiment only sets two screw accommodation slots , see its setting location Figure 6 , basically located in the middle of the LED lens group, and four are set in Embodiment 1;

[0073] In addition, the reinforcing ribs 8' are linear, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com