A combined LED lamp driving module

A technology of LED lamps and drive modules, applied in lighting and heating equipment, components of lighting devices, light sources, etc., can solve the problems of increasing the heat dissipation load of lamps, being unable to deal with them, and accelerating aging, so as to achieve good practicability and flexibility performance, reduce maintenance costs, and improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

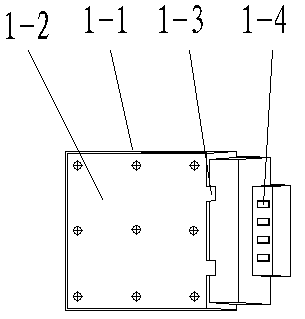

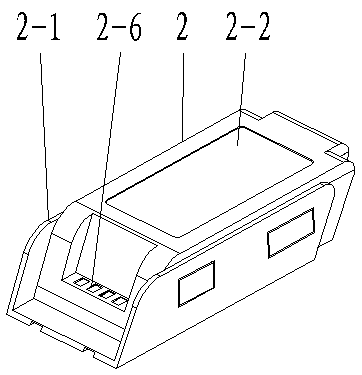

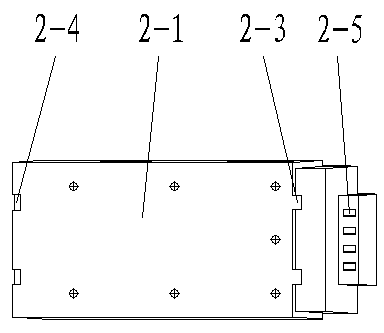

[0032] Please compare figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , the present invention is made up of control box 1 and power supply box 2.

[0033] in:

[0034] The control box 1 is composed of the control box base 1-2, the control box upper cover 1-1 and the controller module and its kit. The size of the control box base 1-2 corresponds to the opening of the control box upper cover 1-1, and one side is flat , the other side has studs for installing the controller module, the bottom plate is reserved with mounting holes corresponding to the mounting studs on the upper cover of the control box 1-1, and two protruding control The box docking positioning buckle 1-3; the control box upper cover 1-1 is a cavity with an opening at the bottom, and the opening is the installation position of the control box base 1-2, that is, the control box base 1 is reserved on the inner side of the opening -2 studs; the front end of the control box upper cover 1-1 has a protrud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com