Process for producing surface-finished lightweight components with high natural fibre content and integrated fastening elements

A lightweight component, natural fiber technology, applied in the direction of coating, can solve the problems of low impact toughness and high cost, and achieve the effect of high shape stability, low inherent stress, and shortened working cycle time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

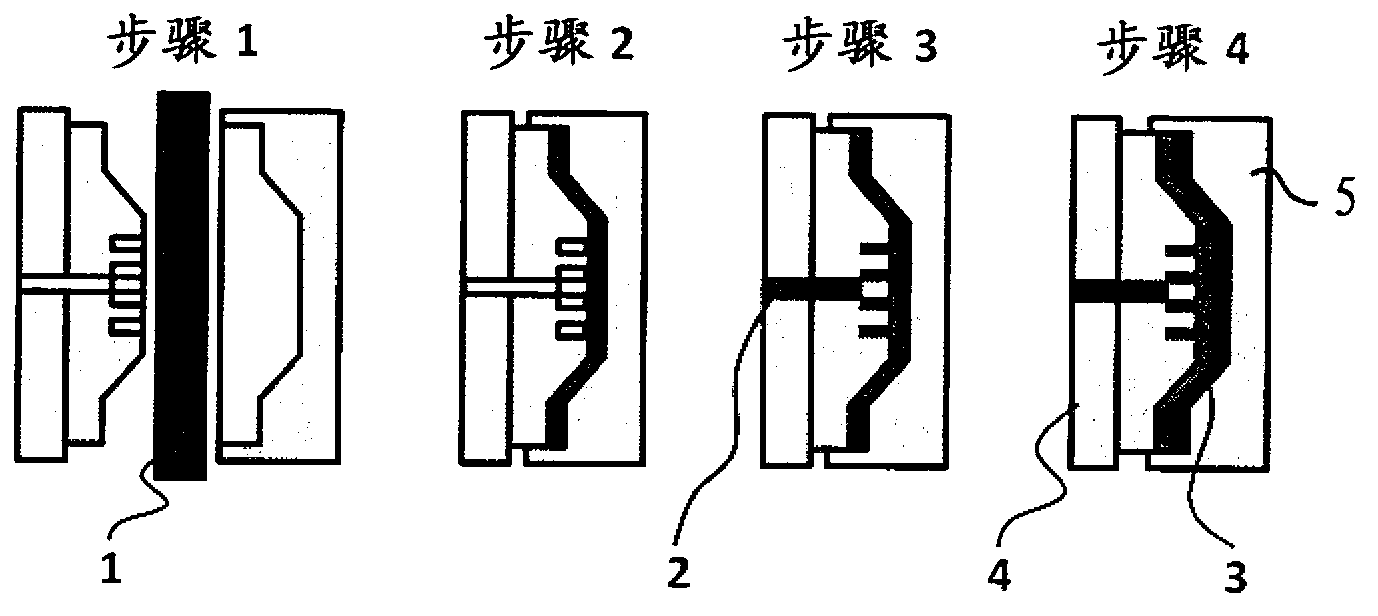

[0049] exist figure 1 Shown in is a general process flow diagram, as described in claim 1. Step 1 shows the preparation of the semifinished product ( 1 ) between a first mold half ( 4 ) on the left side of the semifinished product and a second mold half ( 5 ) on the right side of the semifinished product. In step 2, the natural fiber semi-finished product (1) in the injection molding tool (comprising the first and the second tool half) is pressed, wherein the two mold halves or the two tool halves are moved relative to each other. Step 3 consists in back-injecting the natural fiber semi-finished material at the locations where functional elements such as in particular holding bodies and / or reinforcement structures are provided. The functional element, in particular the holding body and / or the structurally reinforcing plastic material ( 2 ), fills the cavity of the first mold half. Since the natural fiber semi-finished product (1) is not subjected to compression forces in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com