Direct transmission type milling machine

A transmission type and milling machine technology, which is applied in the direction of driving devices, metal processing machinery parts, metal processing equipment, etc., can solve the problems of high energy consumption of multi-stage gear transmission, large loss of motor power, easy damage of clutches, etc., and achieves easy promotion, The effect of increasing the rotation speed and reducing the probability of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

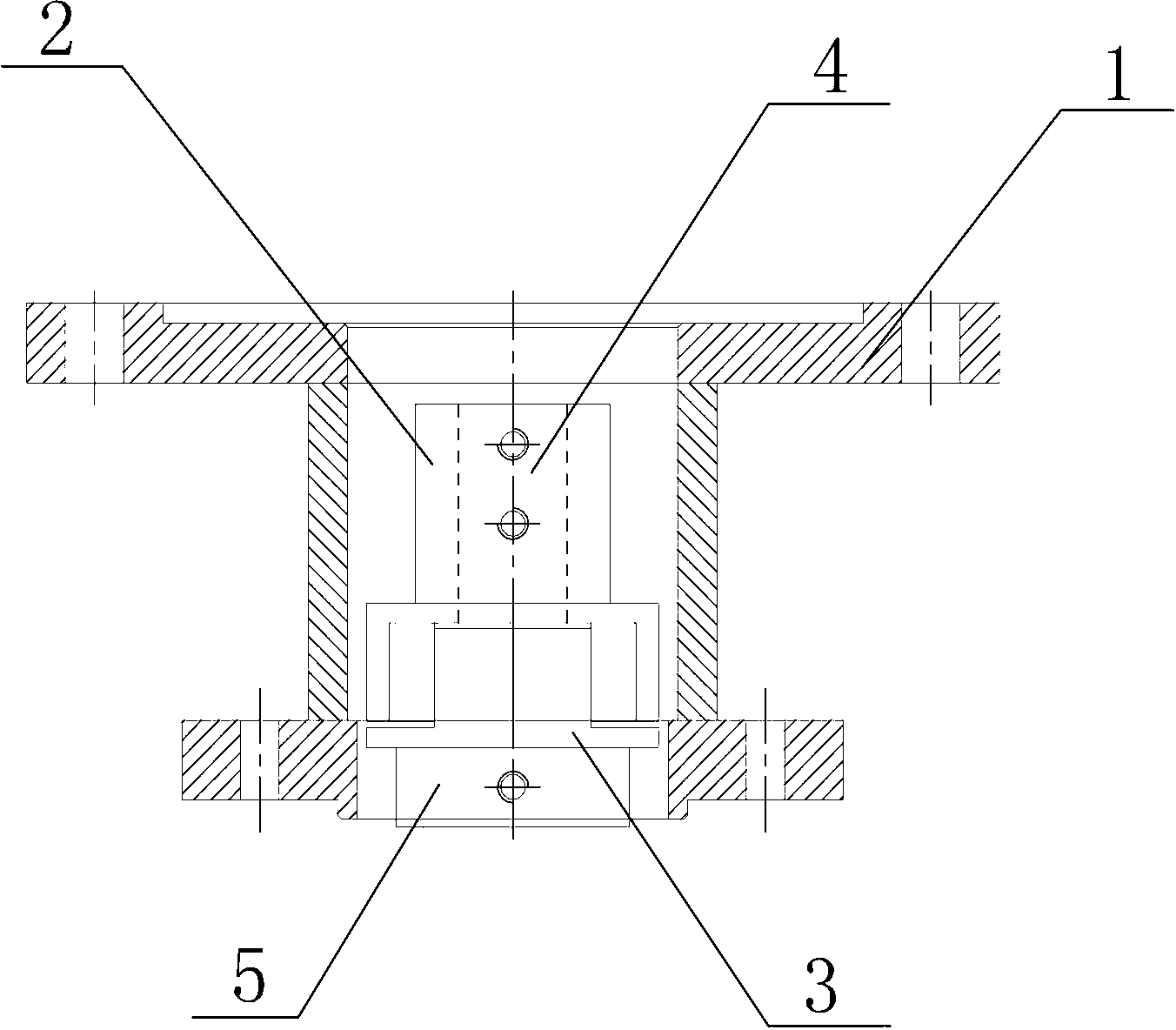

[0013] Embodiment 1: refer to figure 1 , a direct-drive milling machine, including a main shaft 5, a 30KW frequency conversion motor, an upper connection sleeve 2 and a lower connection sleeve 3 are installed on the base 1 of the frequency conversion motor, and the upper and lower connection sleeves are fitted and fastened by the concave and convex parts .

[0014] Have screw hole on the cover body of upper connection cover 2, have flat key keyway in the cover. The 4 ends of the output shaft of the variable frequency motor are inserted into the flat key in the upper connecting sleeve 2 to connect, and then fastened with the upper connecting sleeve 2 by bolts.

[0015] Have screw hole on the cover body of lower connection cover 3, have flat key keyway in the cover. The end of the main shaft 5 is inserted into the flat key in the lower connecting sleeve 3 for connection, and then fastened with the lower connecting sleeve 3 by bolts.

Embodiment 2

[0016] Embodiment 2: The variable frequency motor in Embodiment 1 is replaced by a servo motor, and other features are the same as Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com