Auxiliary plate spring support

A technology of sub-plates and arc-shaped surfaces, applied in the direction of springs, leaf springs, springs/shock absorbers, etc., can solve the problems of unfavorable frame longitudinal beam hole position standardization, poor frame longitudinal beam processing technology, etc., to achieve hole Position, improve the effect of processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

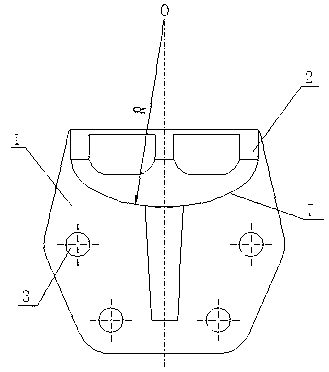

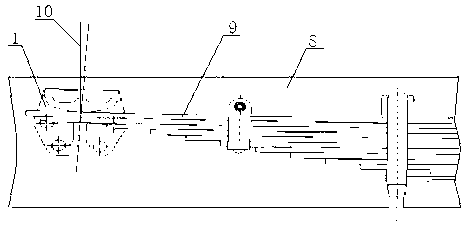

[0016] see Figure 3-Figure 5 , a secondary leaf spring bracket, which is connected to the frame longitudinal beam 8 by bolts or rivets, including a bracket main body 1 and a limit block 2, the bottom of the bracket body 1 is provided with a connecting hole 3, and the limit block The arc curved surface on the block 2 is a support curved surface, and the support curved surface is a curved surface in contact with the auxiliary leaf spring 9 and the auxiliary leaf spring support; the support curved surface is formed by connecting the arc curved surface I4, the arc curved surface II5 and the arc curved surface III6 , the radius of the arc surface I4 is R1, the center of the arc surface I4 is O1, the radius of the arc surface III6 is R2, the center of the arc surface III6 is O2, the circle center O1 of the arc surface I4 and the arc surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com