Method for detecting curvature radius of toroidal mirror through combining contourgraph and interferometer

A technology of curvature radius and interferometer, which is applied in the direction of instruments, measuring devices, and optical devices, can solve the problems of difficult tire surface processing and detection, easy scratching or damage to the sample surface, and incomprehensible measurement accuracy. The effect of high processing difficulty, optimized processing technology, and expanded application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

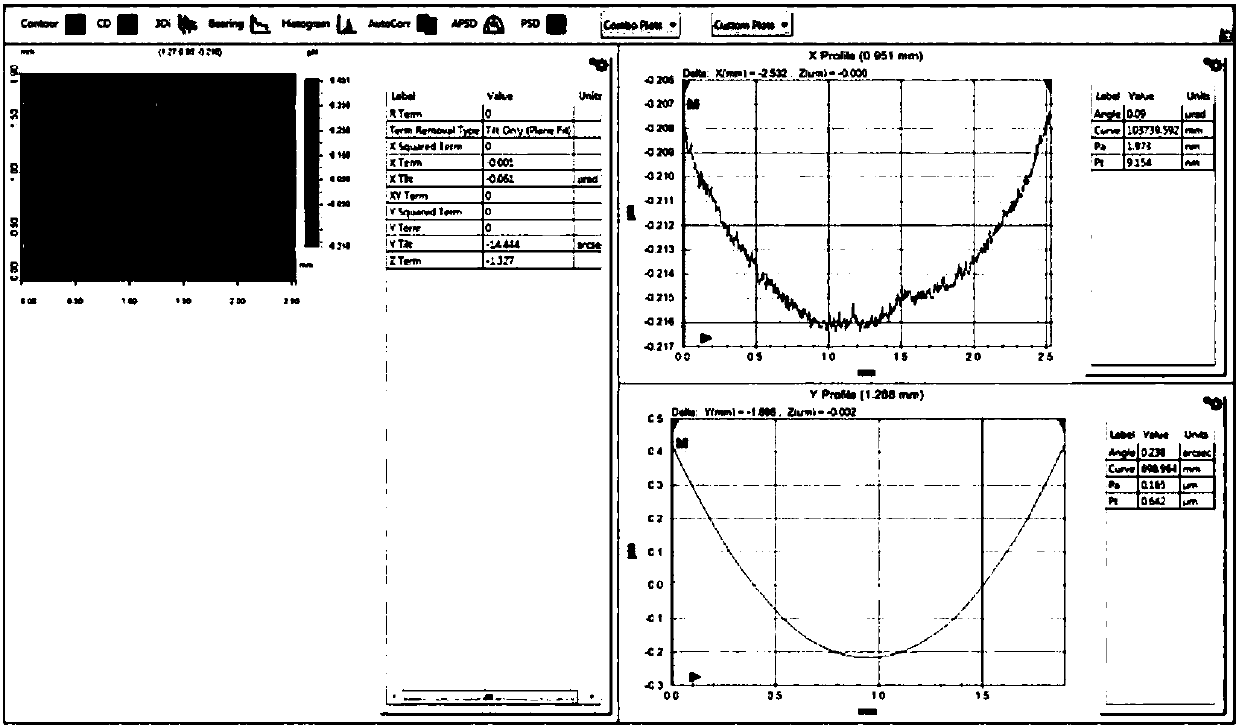

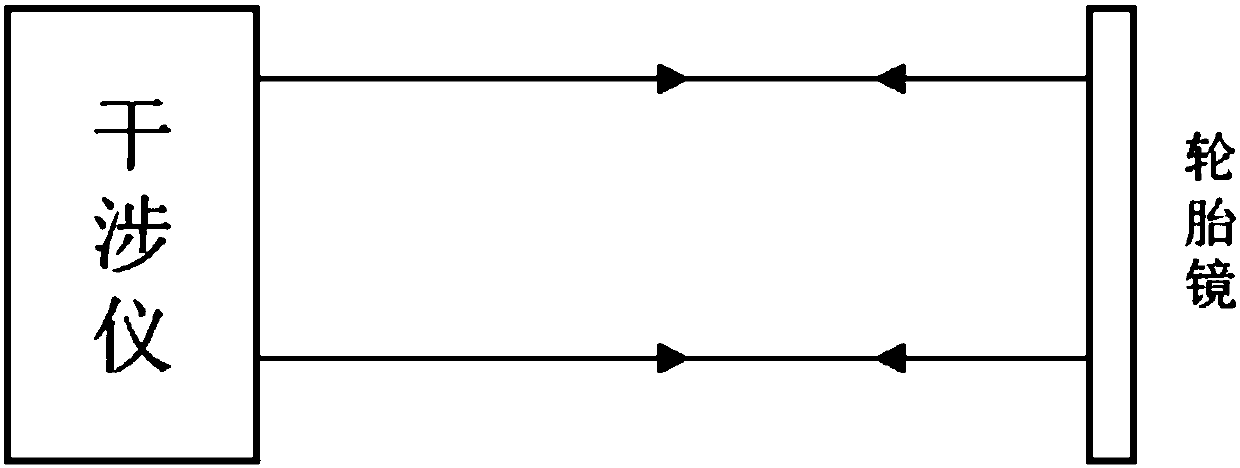

[0030] In this embodiment, the Bruker optical profiler and the Zygo plane interferometer are used to detect the radius of curvature of the tire mirror. The length, width and height of the lens are 510mm×50mm×60mm, the working surface to be tested is 510mm×50mm, and the lens is designed with two radii of curvature Respectively R 1 = 104870mm and R 2 =658.5mm. The radius of curvature specifically includes the following steps:

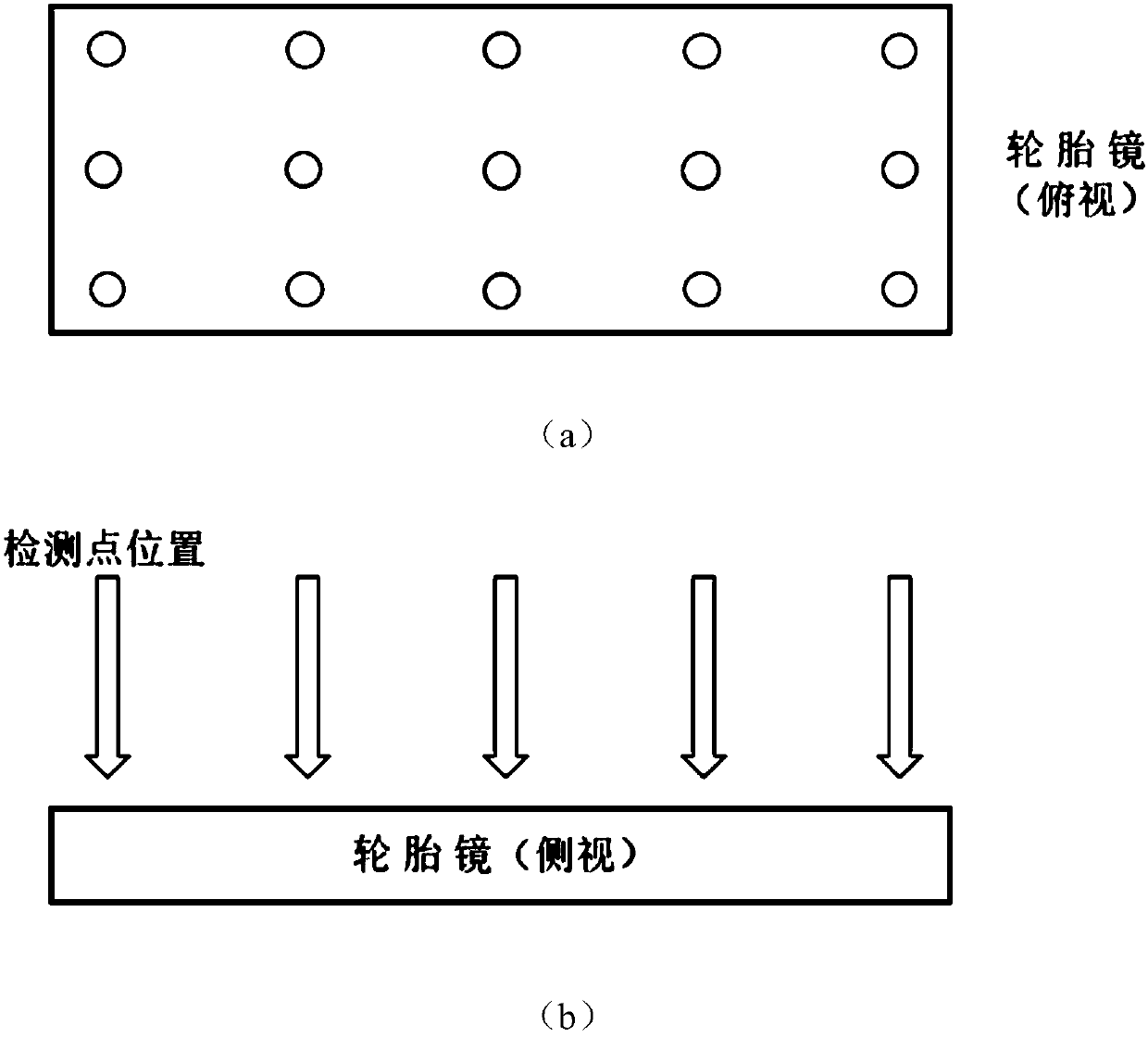

[0031] (1) Place the tire mirror to be tested on the optical profiler, and collect multiple test points from the center to the edge. In this example, test 5 rows of points equidistant in the length direction of the mirror surface, and test 3 points in each row. Using the optical profiler to detect the position of the test point of the tire mirror is as follows: figure 1 As shown, the circle in the figure indicates the position of the test point of the optical profiler, and the 2.5x objective lens is selected to test its surface profile;

[0032] (2) U...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com