Hoop-type circular-section anchor-rod slide-resistant pile and construction method thereof

A technology of anti-sliding piles and circular cross-sections, which is applied in sheet pile walls, foundation structure engineering, buildings, etc., can solve the problem that the anti-sliding piles with circular anchors cannot achieve the expected support effect and cannot fully exert the bending resistance of the pile body , pile body force does not match the design, etc., to achieve the effect of saving pile body materials, facilitating mechanical pile formation, and preventing torque action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

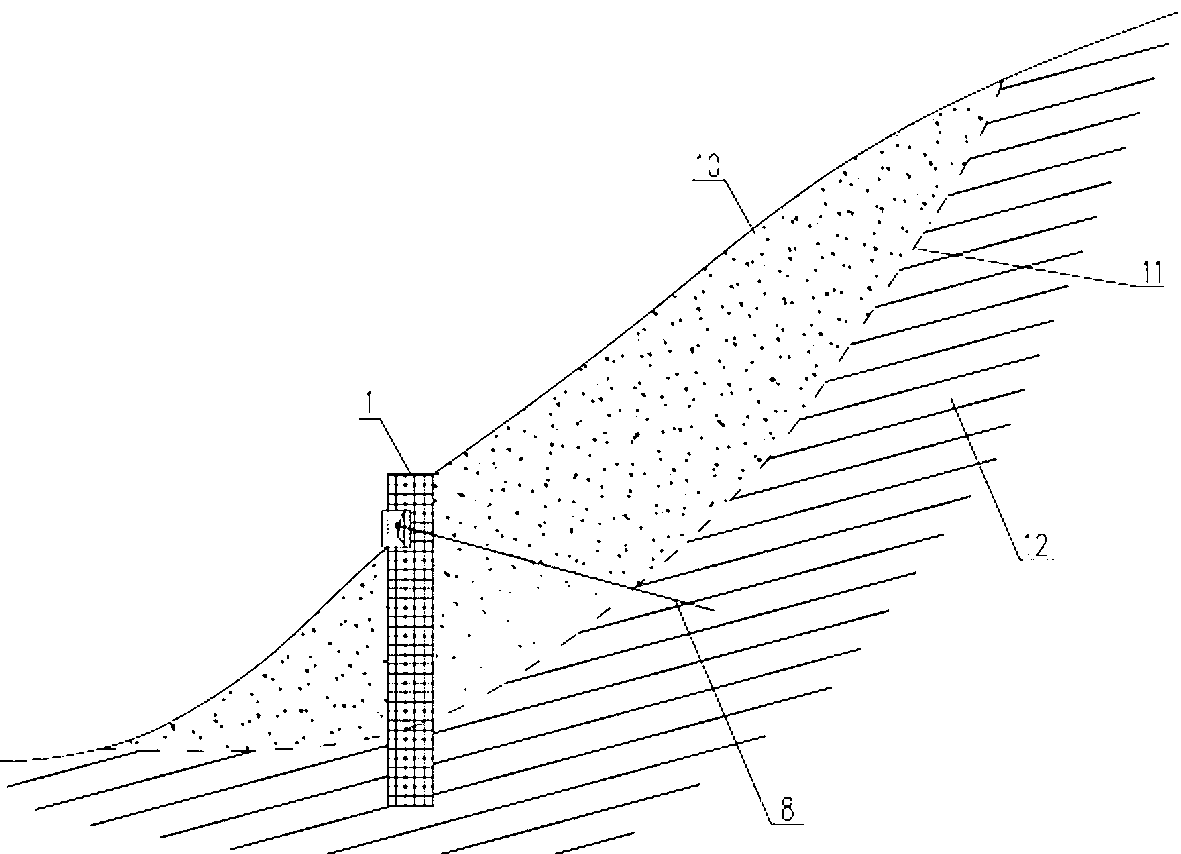

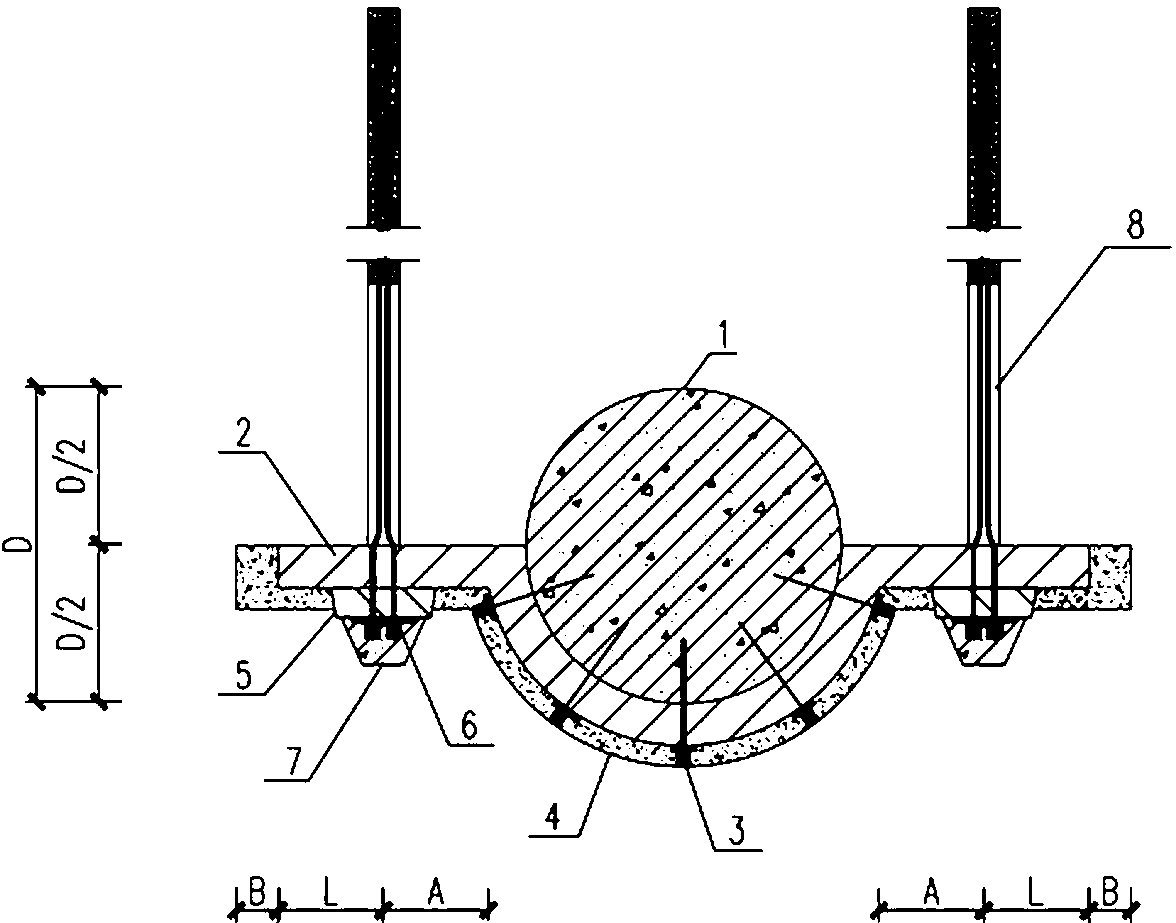

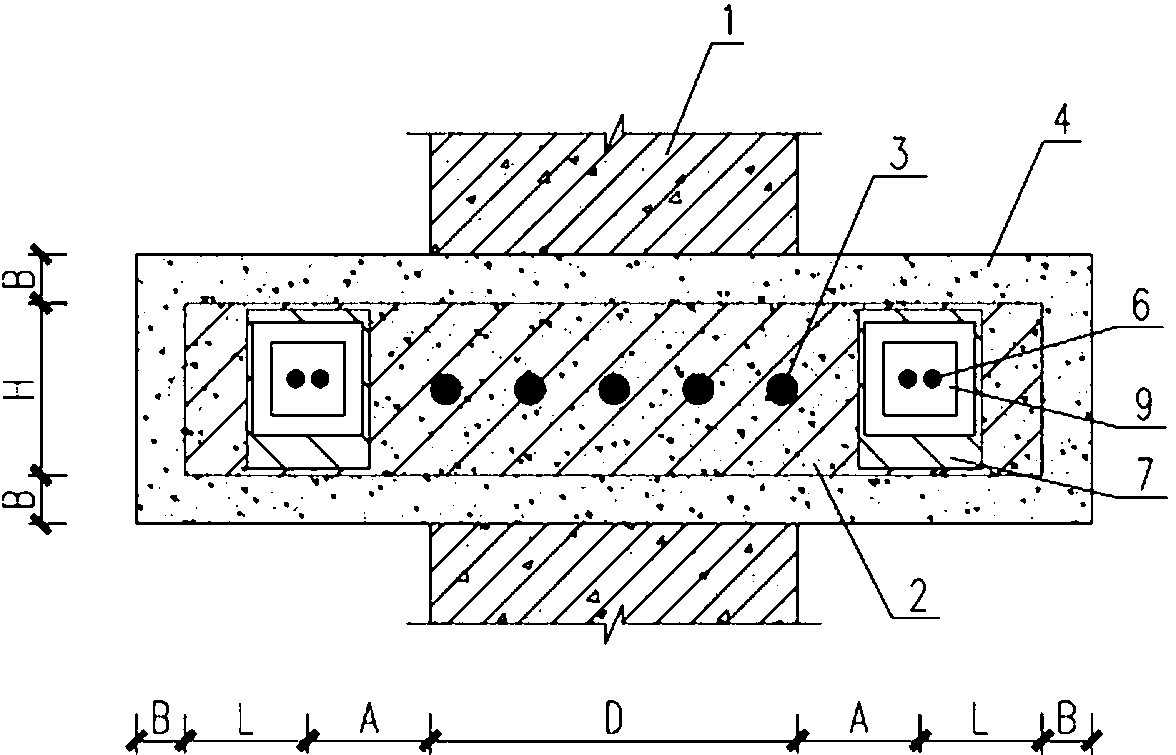

[0027] root tree figure 1 , figure 2 , image 3 , Figure 4 Shown:

[0028] An anti-slide pile with a hoop-type circular section anchor rod, comprising: a circular section anti-slide pile 1, a hoop-shaped steel belt 2, a steel nail 3, an anchor rod 8, an anchor 6, and a hanging net sprayed concrete layer 4; The upper arc surface of the anti-slide pile 1 is hooped with a hoop-shaped steel belt 2, and the anchor rod 8 passes through the anchor bolt reserved hole on the straight section of the hoop-shaped steel belt 2 to connect and anchor, and matches the incident angle of the anchor rod 8 on the outside of the straight section of the steel belt. Set the inclined support 5, set the steel backing plate 9 between the anchorage 6 and the inclined support 5, set the concrete anchor 7 on the inclined support 5, and hang the hanging net sprayed concrete layer 4 and the steel nail 3 outside the hoop steel belt 2 Insert the hanging net sprayed concrete layer 4, the hoop-shaped stee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com