Precast tubular pile and construction method thereof

A prefabricated pipe pile and construction method technology, which is applied to sheet pile wall, foundation structure engineering, construction, etc., can solve problems such as unsuitable construction conditions or geological conditions, inability to push the expanded steel pile tip, affecting the pile sinking construction, etc. To achieve the effect of convenient long pile sinking construction, saving pile material and improving bearing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

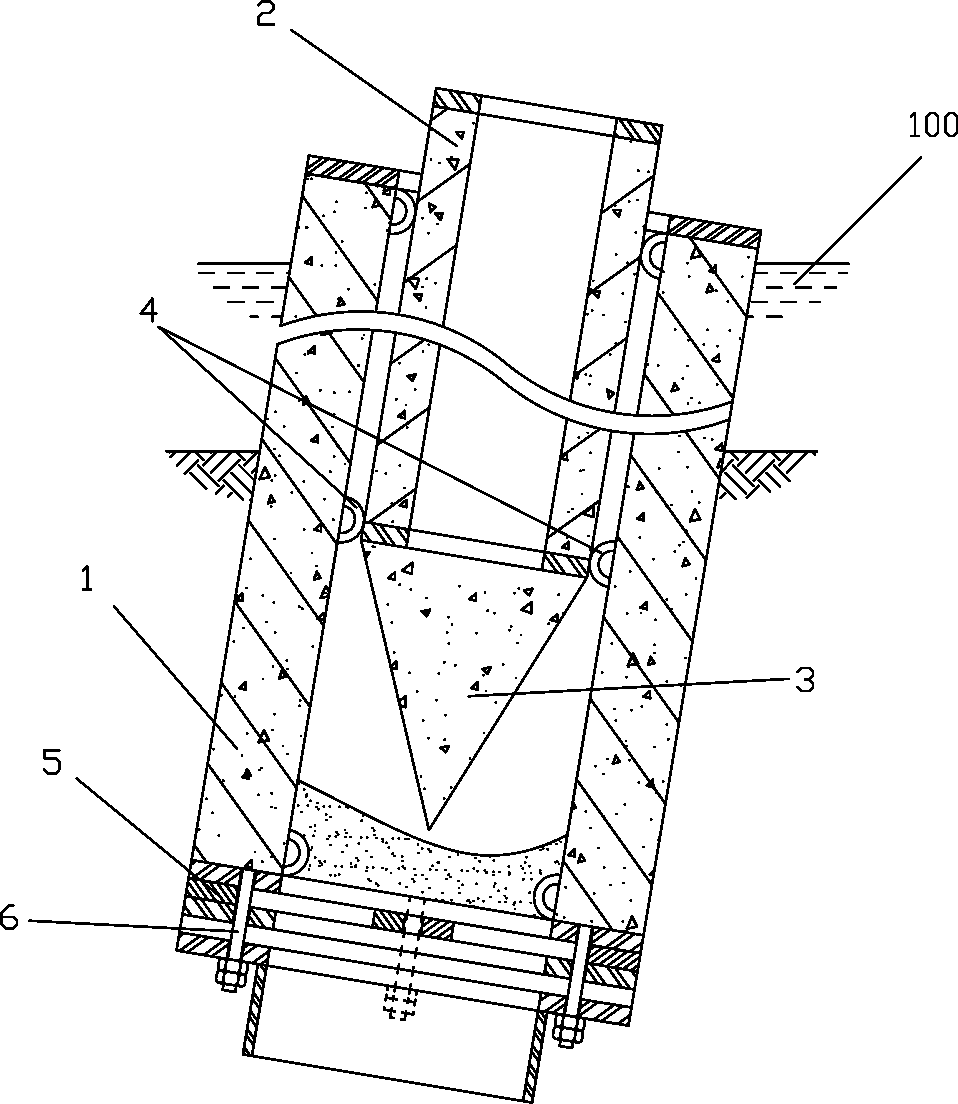

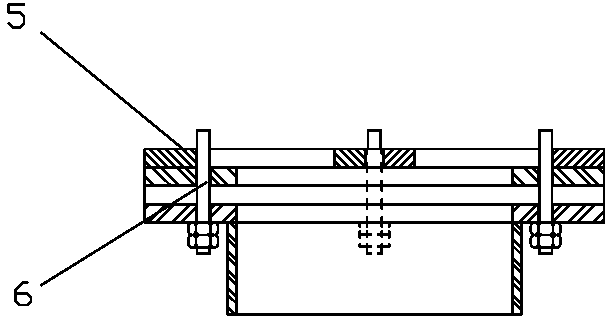

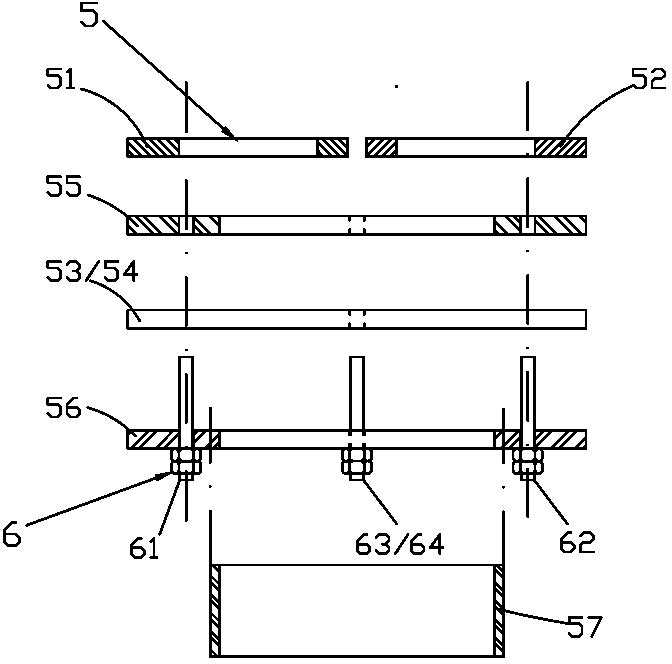

[0042] see Figure 1 to Figure 7 , a kind of prefabricated pipe pile of the present invention, it comprises, the first section prefabricated pipe pile 1; Set in the first section of prefabricated pipe pile 1, the sinking depth of the bottom of the second section of prefabricated pipe pile 2 is greater than the sinking depth of the bottom of the first section of prefabricated pipe pile 1, and the bottom of the second section of prefabricated pipe pile 2 is provided with a concrete cone Shaped pile point or steel plate combined conical pile point 3, the height of the conical pile point 3 is not less than its outer contour diameter; The centering and limiting device 4 of the second section of prefabricated pipe piles, and the centering and limiting device 4 is uniformly and symmetrically arranged along the circumference of the first or second section of prefabricated pipe piles 1 and 2; the expandable steel node 5 is welded or The bolt connection pair 6 is connected to the botto...

Embodiment 2

[0056] see Figure 8 ~ Figure 12 , In this embodiment, the outer diameter of the first precast concrete pipe pile 1 is 500mm, the inner diameter is 300mm, and the length is 10m. At the top, bottom and middle of the inner hole of the first section of prefabricated pipe pile 1, centering limiting devices 4 are respectively symmetrically arranged to constrain the second section of prefabricated pipe pile 2, and the centering limiting devices 4 are four anchored on Arc-shaped ribs in concrete.

[0057] The outer diameter of the second prefabricated pipe pile 2 is 250mm and the length is 30m. The bottom end of the second section of the prefabricated pipe pile 2 is provided with two mutually perpendicular steel plate combined conical pile tips 3, the height of the conical pile tips 3 is 300 mm, and the outer diameter of the pile is 250 mm.

[0058] The expandable steel node 5 is connected to the bottom end of the first section of the prefabricated pipe pile 1 through the bolt conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com