Coaxially-nested multi-section prefabricated tube pile and construction method thereof

A technology of prefabricated pipe piles and construction methods, which is applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of not being able to guarantee the mechanical properties of coaxial nested and superimposed components, and not considering the problem of longitudinal axis alignment, etc. Achieve the effect of reducing pile driving noise and reducing pile sinking resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

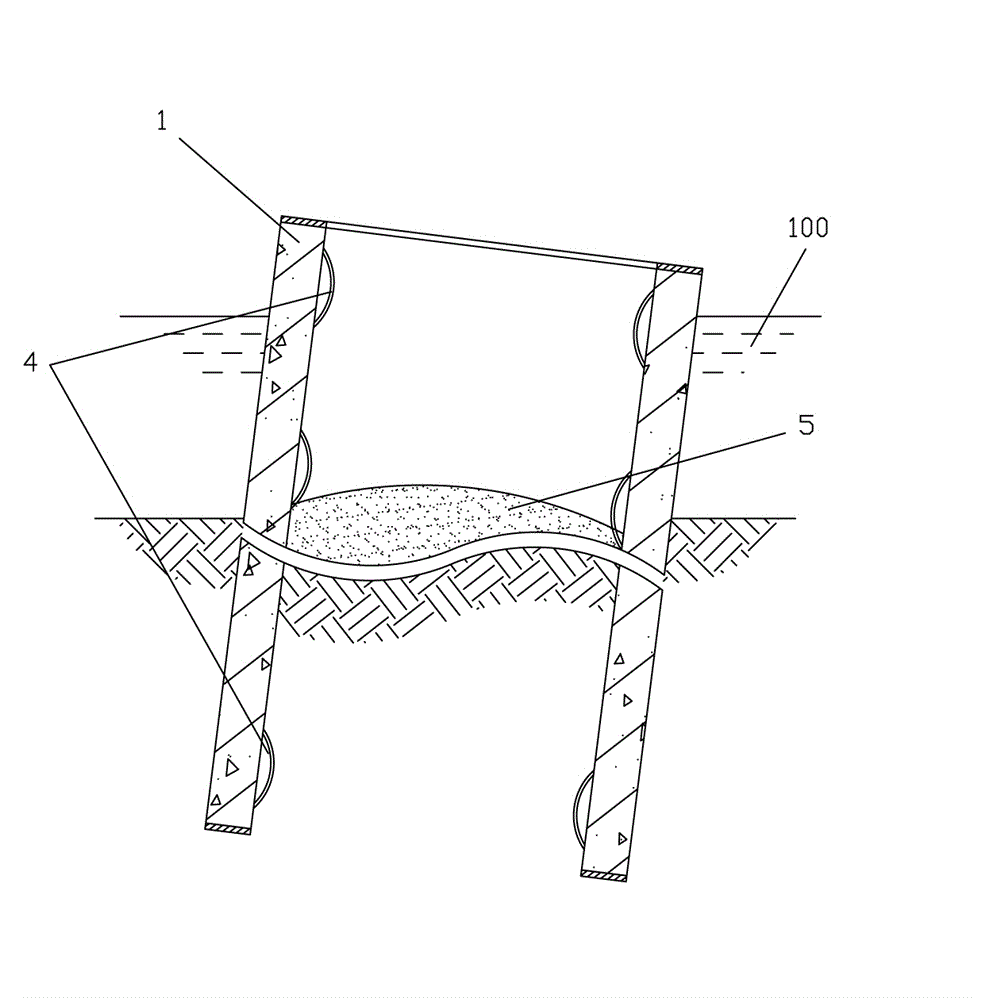

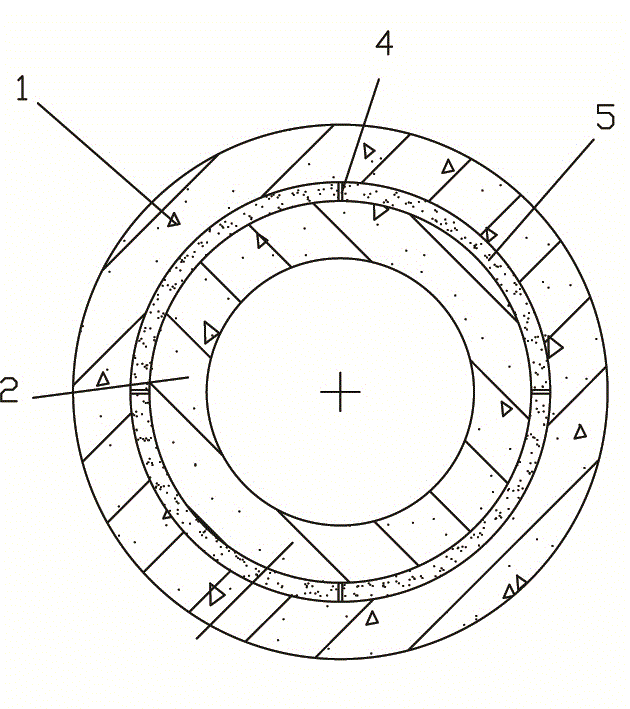

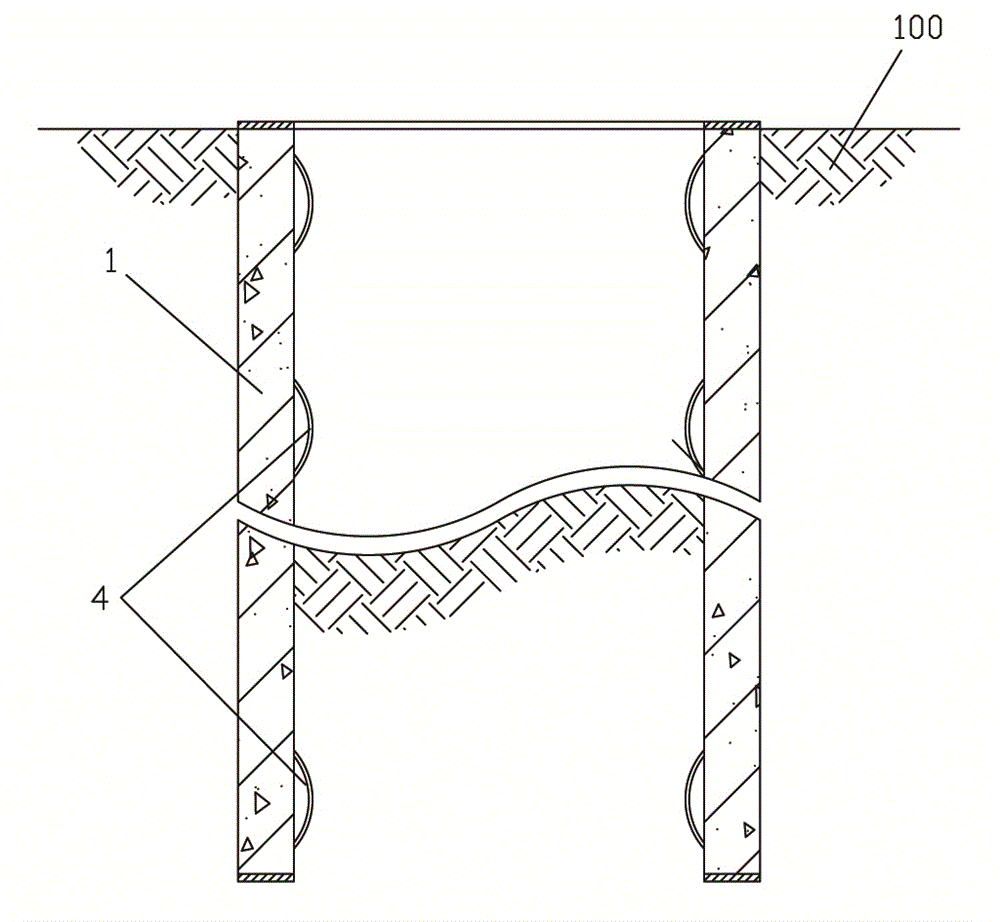

[0040] see Figure 4 ~ Figure 6 , Embodiment 2 of the present invention.

[0041] 1) The outer diameter of the first prefabricated concrete pipe pile 1 is 1400mm, the inner diameter is 1100mm, and the length is 30m. At the top, bottom and middle of the inner hole of the first section of prefabricated pipe pile 1, centering limit devices 4 are symmetrically arranged to constrain the second section of prefabricated pipe pile 2, and each of the centering limit devices 4 is anchored by four It is composed of arc-shaped steel bars in concrete. The diameter of the steel bars is 10mm, the outer chord length of the exposed part of the concrete is 264mm, and the outer vector height is 50mm. axis.

[0042] The outer diameter of the second prefabricated pipe pile 2 is 1000mm, the inner hole diameter is 700mm, and the length is 50m, and the centering and limiting devices are symmetrically arranged at the top, bottom and middle of the inner hole of the second prefabricated pipe pile 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com