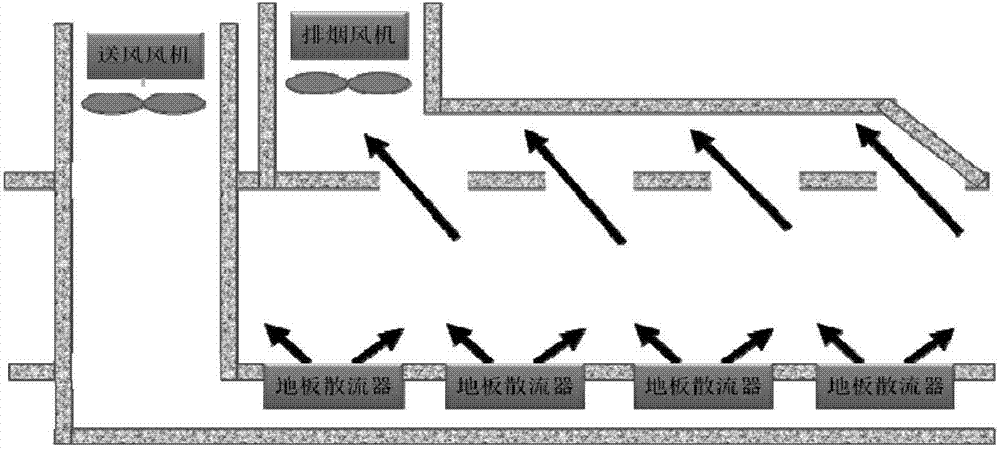

Combination of horizontal and vertical air supply breathing zone collision air supply tunnel fire escape system

An escape system and combined technology, applied in ventilation system, piping arrangement, space heating and ventilation, etc., can solve the problems of impossible complete removal of flue gas, large amount of secondary excavation, large space occupation, etc., to reduce The amount of tunnel excavation, ensuring fresh air demand, and the effect of short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] Specific embodiments of the present invention are provided below, and it should be noted that the present invention is not limited to the following specific embodiments, and all equivalent transformations done on the basis of the technical solutions of the present application all fall within the scope of protection of the present invention.

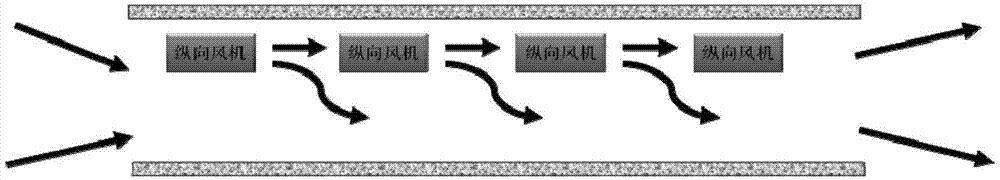

[0045] Comply with the above technical solutions, such as Figure 7 , Figure 8 As shown, the heights of the upper and lower edges of the smoke-shielding vertical wall are 2m and 1.5m respectively; the interface size of the plenum 1 is 2m×1m; the heights of the upper and lower edges of the first nozzle (3) are respectively 2m and 1.5m. Both the width of the second nozzle 4 and the first nozzle 3 are 0.5m; the cross-sectional size of the air supply duct 2 is 0.5m×0.5m. The blowing speeds of the first nozzle 3 and the second nozzle 4 are respectively 0.7 m / s and 0.3 m / s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com