Engine performance simulation method

A simulation method and engine technology, applied in the direction of internal combustion engine testing, etc., to achieve easy-to-master results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

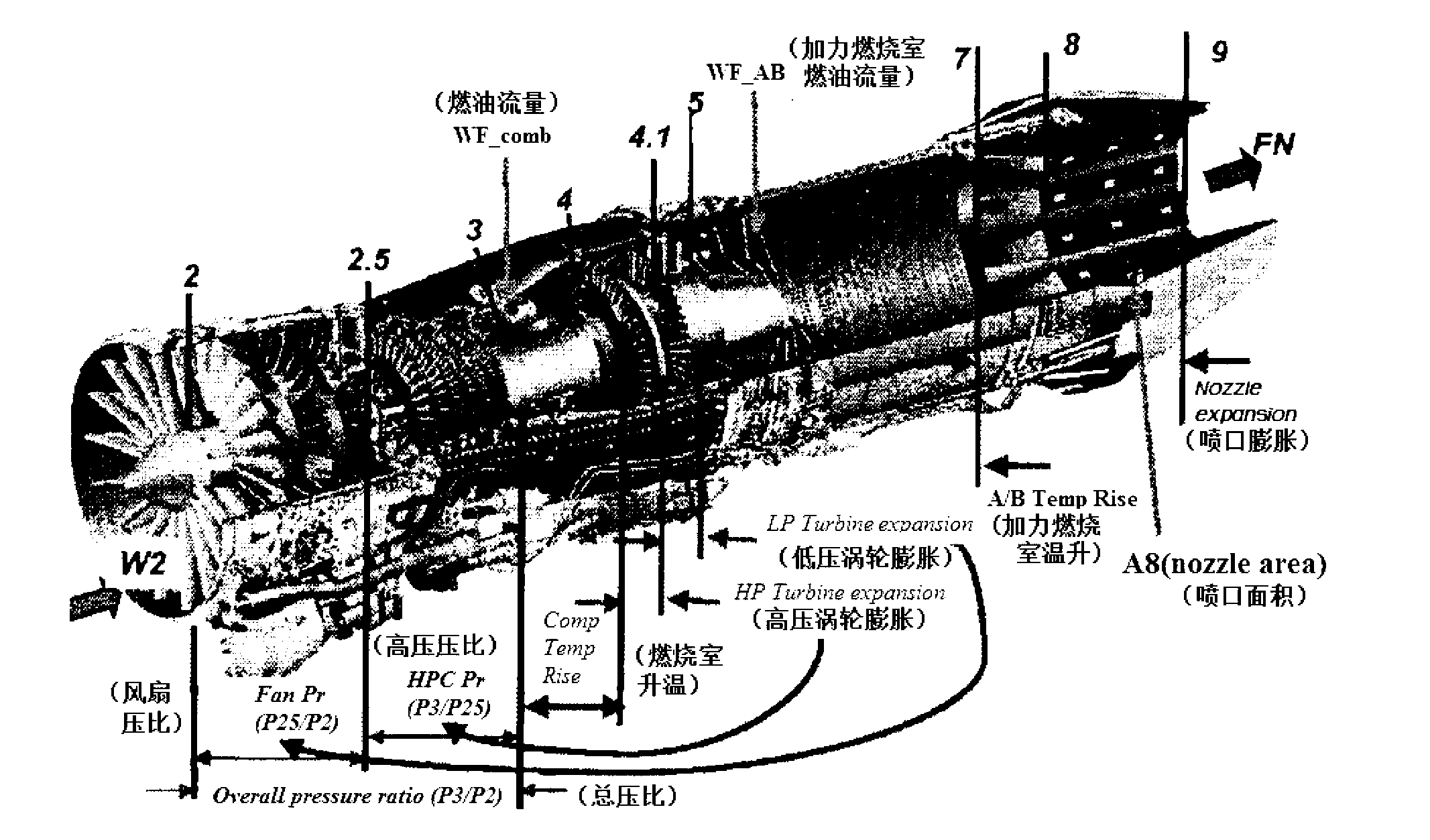

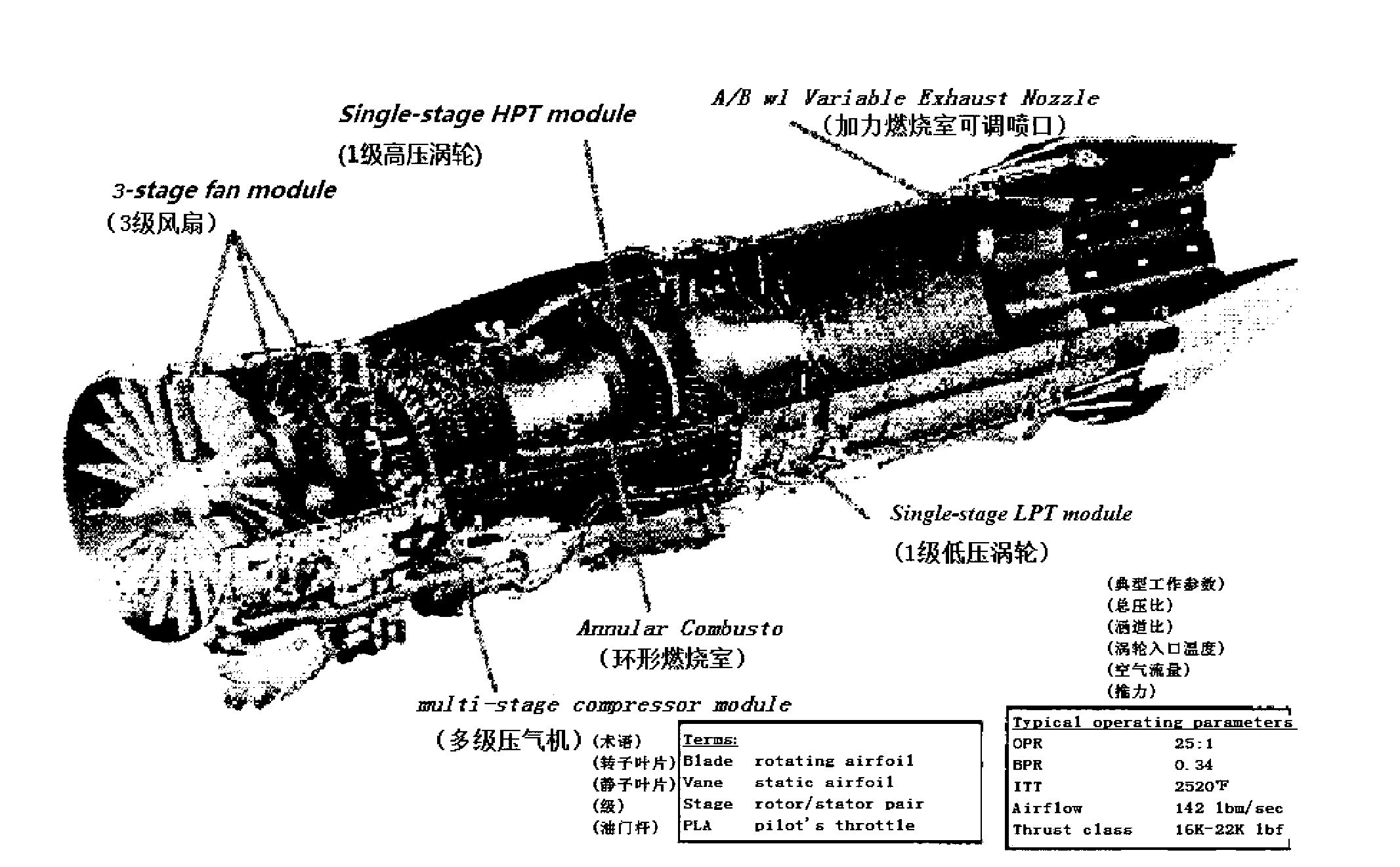

[0058] Embodiment 1 An engine performance simulation method, which uses the following method to calculate engine design point performance and non-design point performance: simulate the performance of an aeroengine through proper matching of components, specifically according to the main components of the engine in the calculation of the overall performance of the engine Due to the differences in the description methods and complexity of the characteristics, the following mathematical model for engine performance calculation is established: each component of the engine is regarded as a "black box", and the characteristics of each component are given without describing the detailed working conditions inside each component ; Then determine the common working point of the engine according to the common working relationship of each component, and complete the engine performance calculation;

[0059]The basic process is: for any selected engine component, draw the power and the path ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com