Gas sensor and intermediate component thereof

A technology for gas sensors and intermediate components, applied in the field of gas sensors and intermediate components, capable of solving the problems of deformation of the embedded part P5 and inability to properly perform assembly operations, etc., preventing deformation of the fitting part, suppressing poor fitting, and easy The effect of assembly work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] In this embodiment, an oxygen sensor for detecting the oxygen concentration in the exhaust gas of an automobile will be described as an example of the gas sensor.

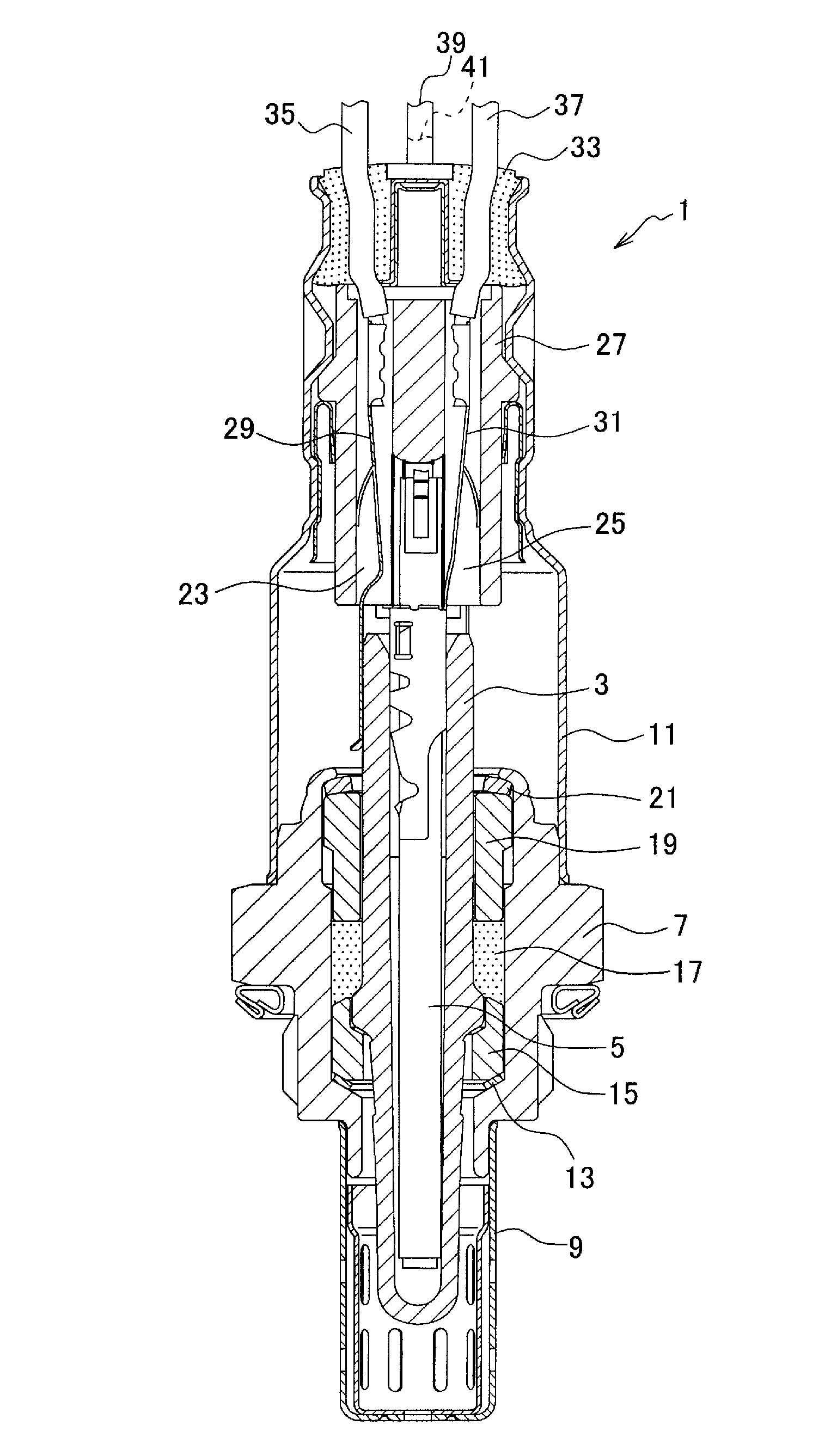

[0052] a) First, based on figure 1 and figure 2 The oxygen sensor of this embodiment will be described. In addition, in figure 1 and figure 2 In , it is shown that the front end side of the oxygen sensor is the lower side and the rear end side is the upper side.

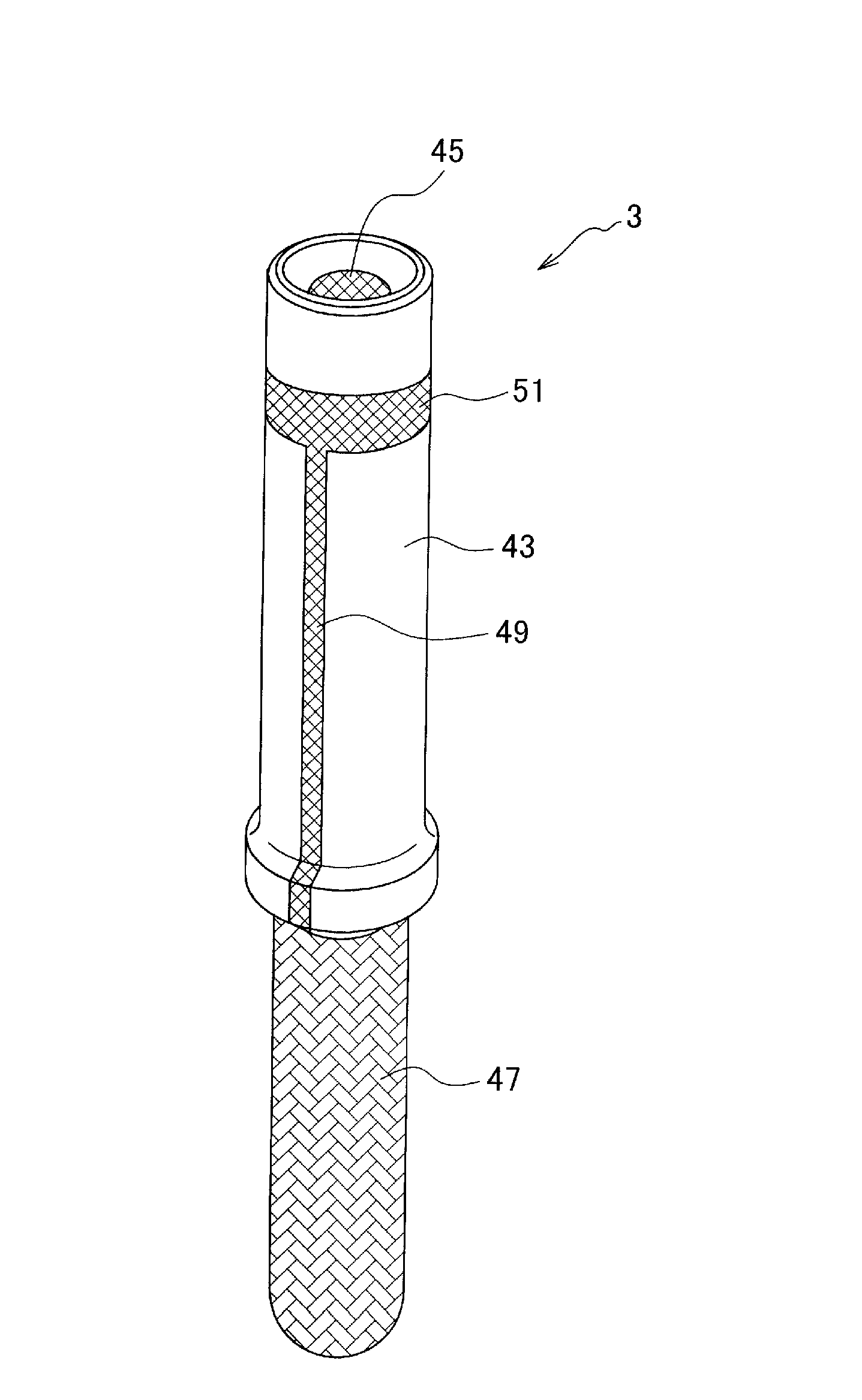

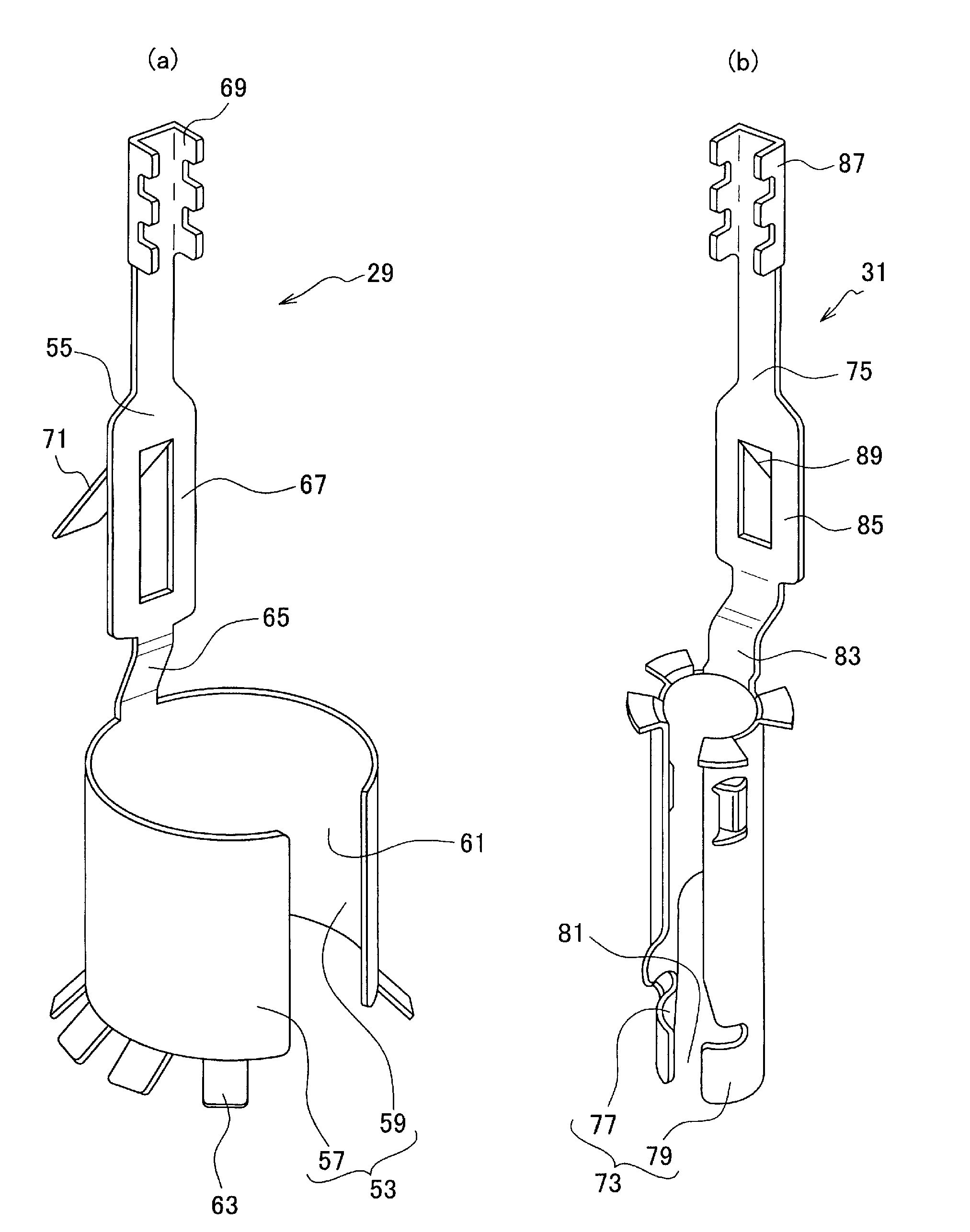

[0053] like figure 1 As shown, the oxygen sensor 1 of this embodiment includes: a cylindrical sensor element 3, which is elongated and closed at the top; a cylindrical ceramic heater 5, which is inserted into the inside of the sensor element 3; The main body metal case 7, which is inserted and fixed by the sensor element 3; the cylindrical metal protector 9, which is installed on the top end side of the main body metal case 7 coaxially with the main body metal case 7; and the cylinder Shaped metal outer cylinder 11 is attached to the rea...

Embodiment 2

[0102] Next, Embodiment 2 will be described, and descriptions of the same contents as those in Embodiment 1 will be omitted.

[0103] Since this embodiment differs from the above-described Embodiment 1 only in the shape of the partition, the partition will be described.

[0104] like Figure 8 As shown in (a) and (b), the separator 121 used in the oxygen sensor of this embodiment is the same as that of the above-mentioned embodiment 1, and is in the shape of a cylinder. 1 with the same shape) through holes 123-129.

[0105] In addition, protrusions (first to fourth protrusions) 131 to 137 are provided at four positions in the circumferential direction at equal intervals between the through holes 123 to 129 .

[0106] In particular, in this embodiment, the protruding parts 131 to 137 are not integral members as in the first embodiment, and the protruding parts 131 to 137 are formed concentrically with the central axis of the partition 121 by overlapping their planar shapes. ...

Embodiment 3

[0111] Next, Embodiment 3 will be described, and descriptions of the same contents as those in Embodiment 1 will be omitted.

[0112] Since this embodiment differs from the above-described Embodiment 1 only in the shape of the partition, the partition will be described.

[0113] like Figure 9 As shown, the separator 151 used in the oxygen sensor of this embodiment has the same cylindrical shape as the above-mentioned embodiment 1, and through holes 153 (same shape as the above-mentioned embodiment 1) are opened at four positions in the axial direction. ~159.

[0114] In addition, between the respective through holes 153 to 159 , protrusions (first to fourth protrusions) 161 to 167 are provided at four positions in the circumferential direction at substantially equal intervals.

[0115] In this embodiment, the outer embedded portion 171 of the outer connection terminal 169 is also fixed to the outer peripheral surface of each protruding portion 161 - 167 by its own elasticit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com