Ball head positioning device for positioning irregular workpieces in combined clamp and positioning method of ball head positioning device

A positioning device and combined fixture technology, applied in positioning devices, metal processing mechanical parts, clamping and other directions, can solve problems such as inability to position irregular workpieces, avoid complex calculations and conversions, direct data, and improve accuracy and stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

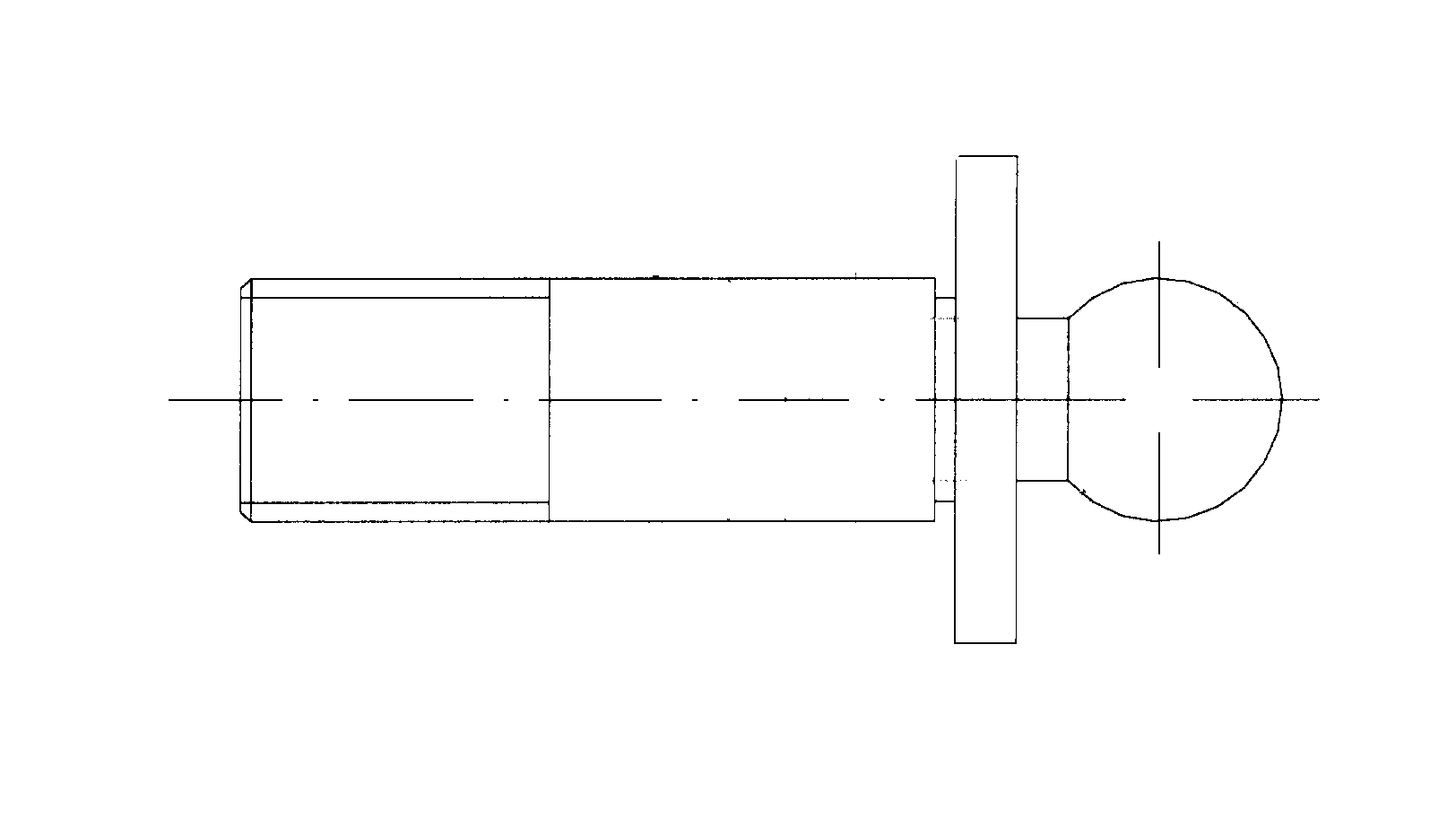

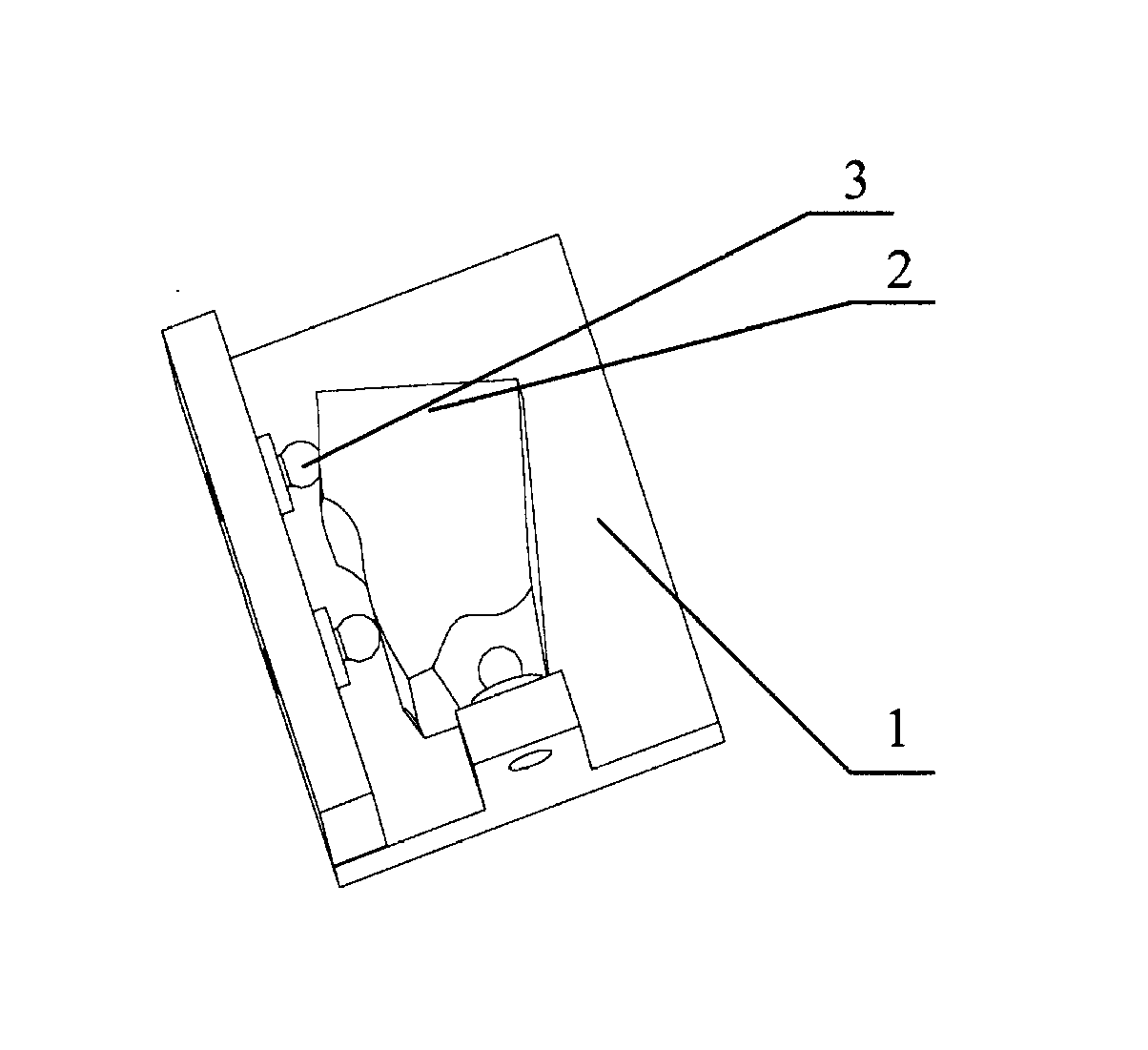

[0016] Such as figure 1 As shown, the ball head positioning device for positioning irregular parts in the combined fixture, the ball head positioning device 3 includes a sphere, a circular platform and a cylinder, the above three are connected in sequence and the center lines of the three coincide, and the cylinder The end car has threads, and the cylinder is threadedly connected with the clamp base 1 .

[0017] A positioning method for positioning irregular parts in a combined fixture, which uses the above-mentioned ball head positioning device, includes the following steps:

[0018] (1) Carry out computer simulation positioning first, that is, place the workpiece 2 to the correct position, and place the ball head positioning device 3 near the surface to be positioned. When the ball head positioning device 3 is placed on the fixture base 1, it must ensure its The center line is not only parallel to the horizontal plane of the fixture base 1 but also perpendicular to the vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com