Corridor transportation device

A technology for transportation devices and corridors, applied in the field of transportation devices in corridors, can solve the problems of increased construction costs, construction interference along the line, high labor intensity, etc., and achieve the effects of avoiding slippage, fast transportation speed, and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

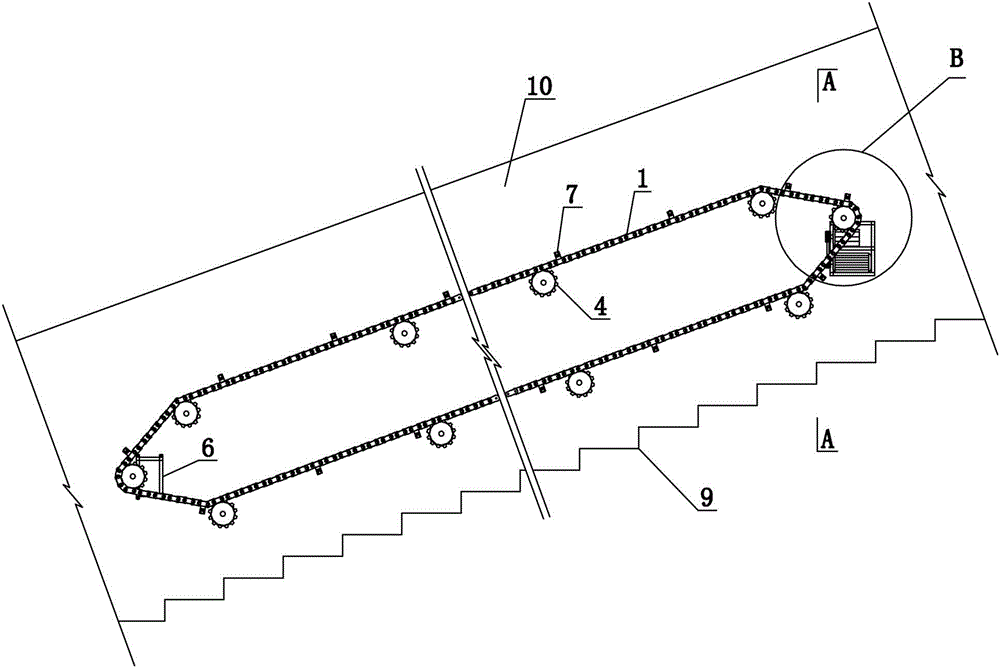

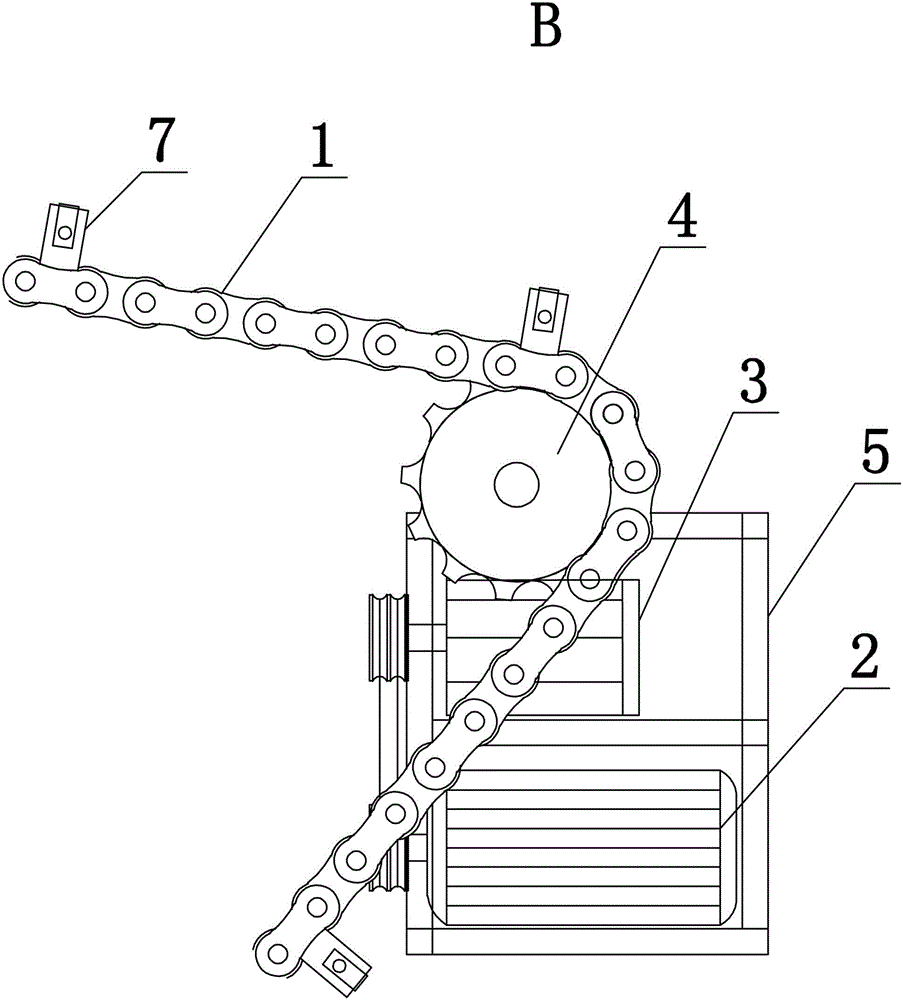

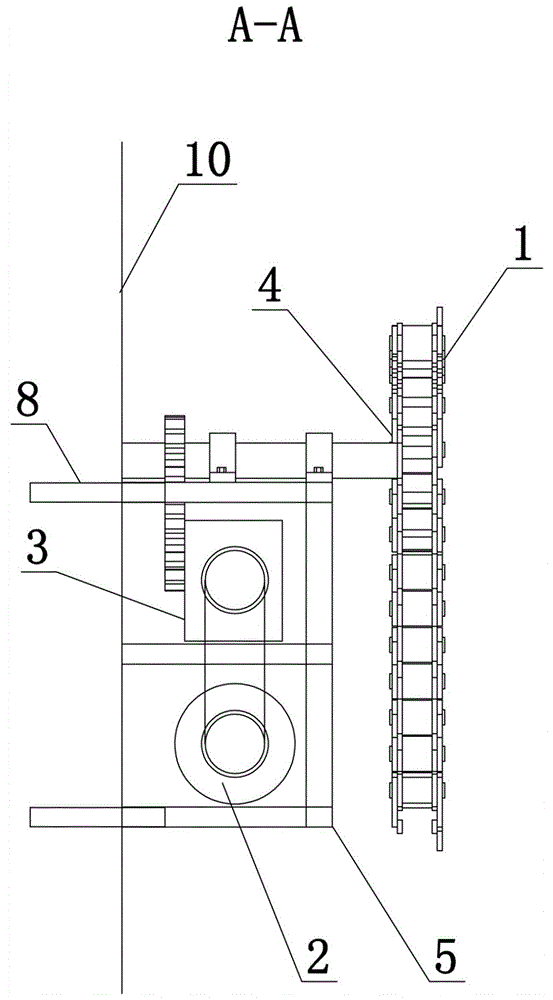

[0025] Such as Figure 1-3 Among them, a transportation device in a corridor, a plurality of sprockets 4 are arranged on the side wall 10 of the corridor through a driven wheel bracket 6, and at least one driving wheel frame 5 is arranged, and the driving wheel frame 5 is fixed on the side of the corridor through an anchor rod 8 On the wall 10, the driving sprocket on the driving wheel frame 5 is connected with the driving device, and the chain 1 connects the driving sprocket and each sprocket 4, and forms a chain conveying device circulating along a section of corridor 9. There are multiple suspension hooks 7 . The drive in this example is figure 2 As shown in , the motor 2 installed on the drive wheel frame 5 is connected to the gearbox 3, and the gearbox 3 is connected to the drive sprocket, the rotation of the motor drives the drive sprocket to rotate, and the chain 1 is driven to rotate accordingly, and each driven The sprocket 4 rotates thereupon, and the waste slag o...

Embodiment 2

[0027] An optimized solution such as Figure 4-6 Among them, on the basis of Embodiment 1, a track 11 is also provided on the top of the corridor. In a preferred solution, the track 11 is arranged on the side of the corridor top close to the chain 1 . Track 11 below is provided with the slide device with roller 14, is provided with chain block 17 on the slide device, and traction rope 16 one ends are connected with slide device, and the other end is connected with suspension hook 7 on the chain 1. A hanging basket 18 is also provided below the chain block 17 .

[0028] An optimized solution such as Image 6 Among them, the track 11 is two channel steels with grooves opposite to each other. The back of the channel steel is welded and connected with the anchor bar 12 fixed on the top of the corridor, and the connecting plate 13 is welded at the joint of the track to enhance its overall strength. The sliding device The two ends of the shaft are provided with rollers 14, and the...

Embodiment 3

[0030] For inclined corridors, it is dangerous to only adopt the scheme of embodiment 2, for example, when the traction rope 16 may break, it will cause the weight in the hanging basket 18 to slide backwards and cause an accident. On the basis of Example 2, the further optimized scheme is as Figure 4-8 Among them, a one-way braking device 19 is also provided in the sliding device.

[0031] Such as Figure 5 , 7 , 8, in the one-way braking device 19, one end of the upper wedge 191 and the lower wedge 192 is located in the groove of the track 11, and a spring 193 is arranged between the upper wedge 191 and the lower wedge 192 The other end of upper wedge 191 and lower wedge 192 is movably connected with the shaft, the traction rope 16 is connected with upper wedge 191 and lower wedge 192 respectively, and the other end of traction rope 16 passes guide hole 194 and traction hole 15. Usually, the one-way braking device 19 is arranged in the groove of each rail 11 to ensure tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com