Adjusting roller carrier of flatcar

A technology of roller frame and flat car, which is applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problem that the V-shaped support cannot adjust the width automatically, and achieve the effect of stable placement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

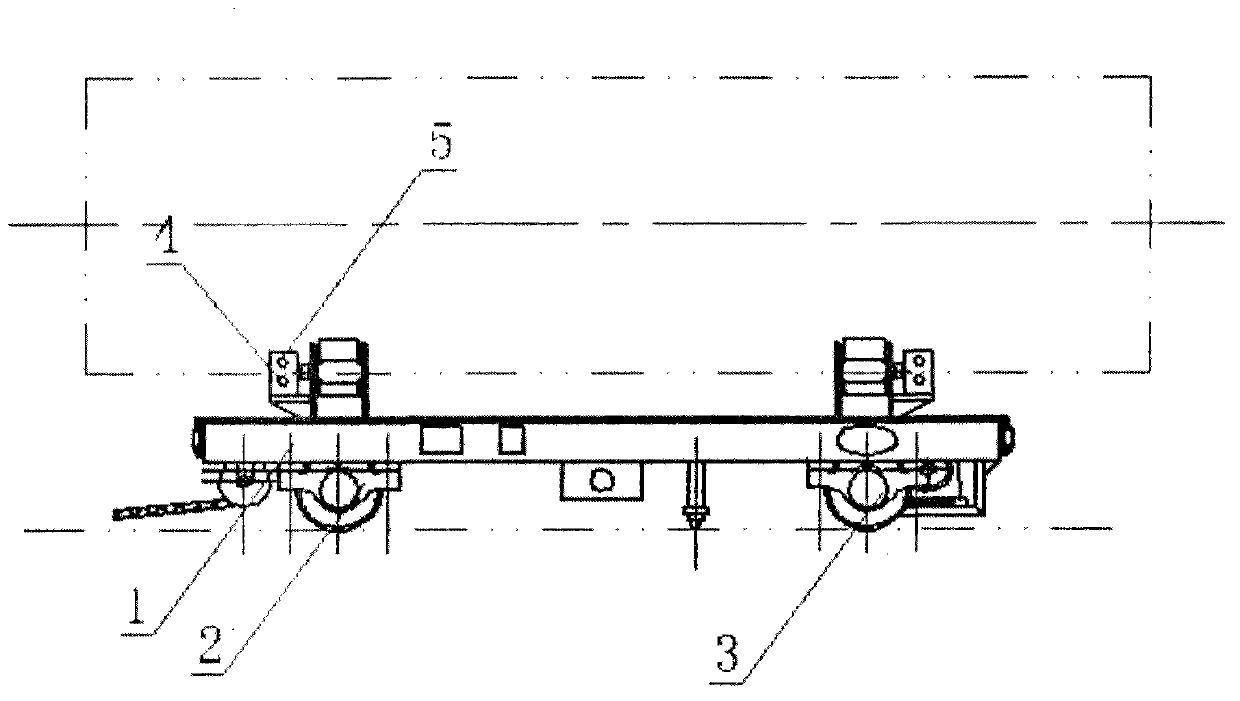

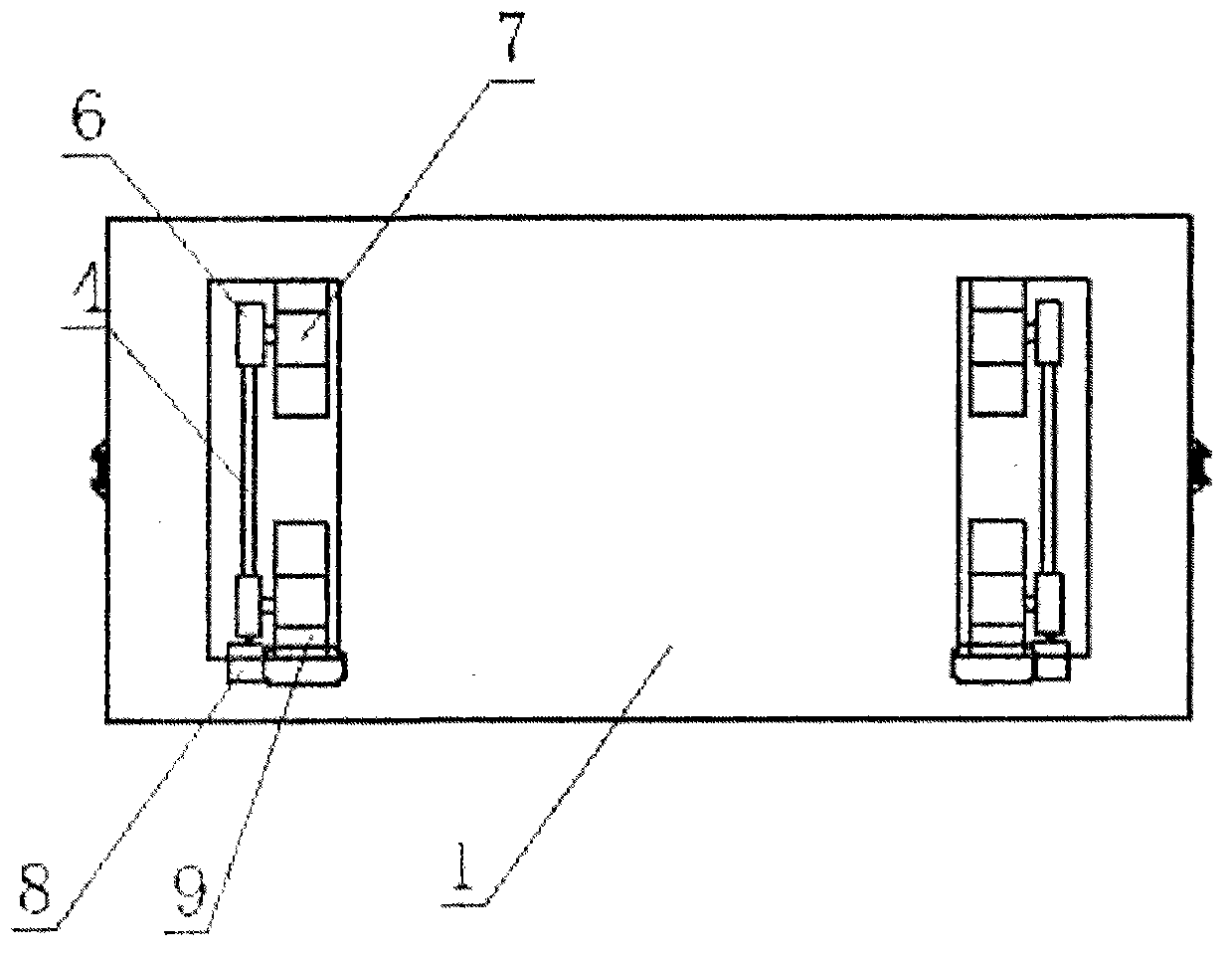

[0010] Such as figure 1 and figure 2 As shown, a roller frame of a flat car includes a flat car frame 1. The front part of the flat car frame 1 is provided with a driven wheel group 3, and the rear part is provided with a driving wheel group 2. There are two planes on the flat car frame. Roller groups uniformly arranged along the length direction of the flat car, two roller groups are arranged symmetrically along the mid-plane in the length direction, each roller group includes two roller frames 7 symmetrically arranged on the upper plane width direction of the flat car frame, each A shift fork is hinged on each roller frame 7, and the shift fork includes a pair of swing arms, an obtuse angle greater than 90 degrees and less than 180 degrees is formed between the two swing arms, and one end of the two swing arms is connected to form a V-shaped structure as a whole. The two shift forks of each group of roller frames are symmetrically placed, and the obtuse angle side is inwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com