A wetting dust catcher

A technology of nonylphenol polyoxyethylene ether by weight percentage, applied in the field of chemistry, can solve the problems of limited use of spray water mist dust reduction method, insignificant secondary dust effect, low dust removal efficiency, etc., and achieves suppression of secondary dust and dust removal. Good effect and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

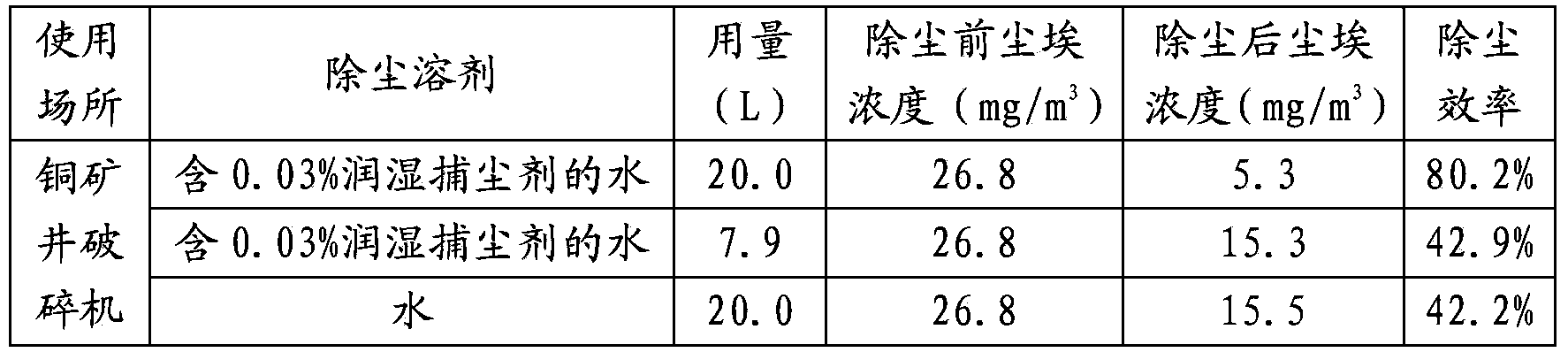

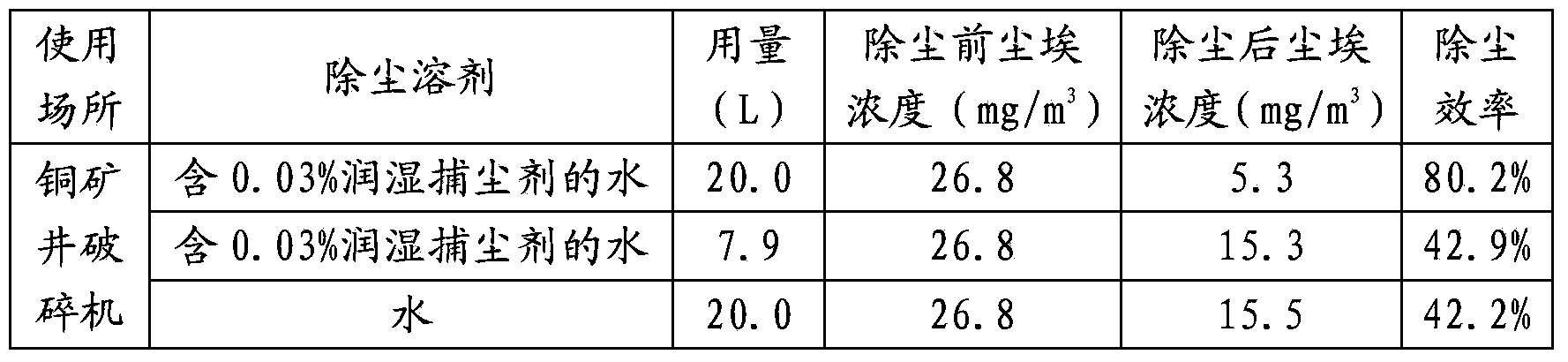

Image

Examples

Embodiment 1

[0013] Weigh the following components by weight percentage: 27% nonylphenol polyoxyethylene ether, 13% sodium laurate, 35% ethylene glycol, and 25% water; mix the components well to obtain a wet dust catcher .

[0014] When using the wetting dust-catching agent prepared in this example to remove dust, first dilute it with water, and the mass fraction of the wetting dust-catching agent is 0.02-0.05%.

Embodiment 2

[0016] Weigh the following components by weight percentage respectively: 30% nonylphenol polyoxyethylene ether, 10% sodium laurate, 30% ethylene glycol, and 30% water; mix the components well to obtain the wet dust catcher .

[0017] When using the wetting dust-catching agent prepared in this example to remove dust, first dilute it with water, and the mass fraction of the wetting dust-catching agent is 0.02-0.05%.

Embodiment 3

[0019] Weigh the following components by weight percentage respectively: 28% nonylphenol polyoxyethylene ether, 9% sodium laurate, 38% ethylene glycol, and 25% water; mix the components well to get the wet dust catcher .

[0020] When using the wetting dust-catching agent prepared in this example to remove dust, first dilute it with water, and the mass fraction of the wetting dust-catching agent is 0.02-0.05%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com