Nitrogen dilution anti-explosion system in dry-method cooling and purifying recovery system for converter gas

A technology of explosion-proof system and recycling system, which is applied in the direction of manufacturing converters and improving process efficiency to avoid explosions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

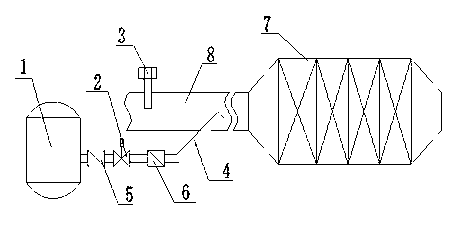

[0012] In order to detect and control the components of the flue gas entering the electrostatic precipitator and prevent explosions, this embodiment provides a figure 1 The nitrogen dilution explosion-proof system in the converter gas dry method cooling purification recovery system shown is mainly composed of a nitrogen tank 1, a pneumatic fast valve 2 installed on the nitrogen pipeline 4, and a gas analyzer installed on the smoke inlet pipe of the electrostatic precipitator. Instrument 3 and a controller that controls the opening or closing of the pneumatic quick valve 2 according to the collected signal of the gas analyzer 3. The gas analyzer 3 installed on the flue gas inlet pipe 8 before the flue gas enters the electrostatic precipitator 7 can timely detect the flue gas composition, and when the flue gas is within the explosion limit range, open the nitrogen gas pipeline through the controller (control system) The pneumatic fast valve 2 on 4 instantly sprays nitrogen into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com