A servo control system and working method of a plc-free suspended spindle type roving frame

A technology of servo control system and working method, which is applied in spinning machine, continuous winding spinning machine, textile and paper making, etc., can solve the problems of low efficiency, hysteresis, error proneness, etc., to reduce hardware cost, Precise control and reduce the effect of failure links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

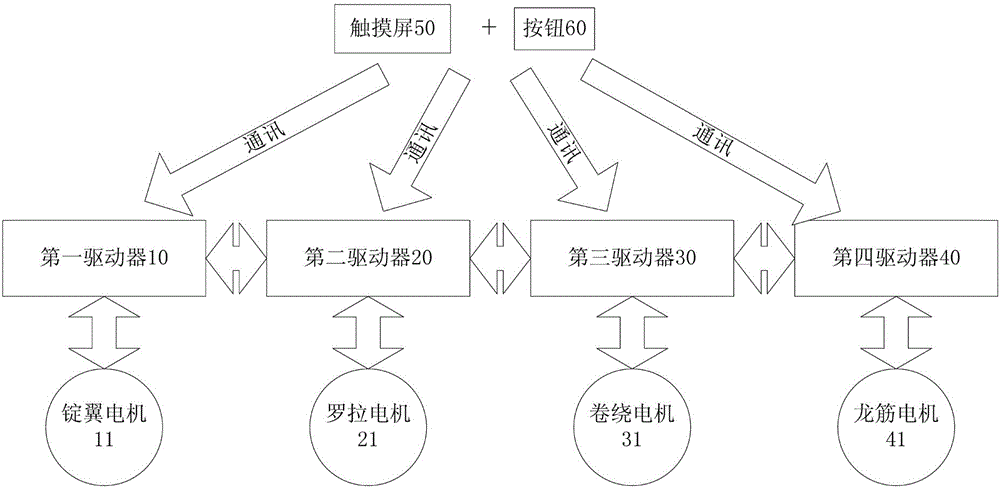

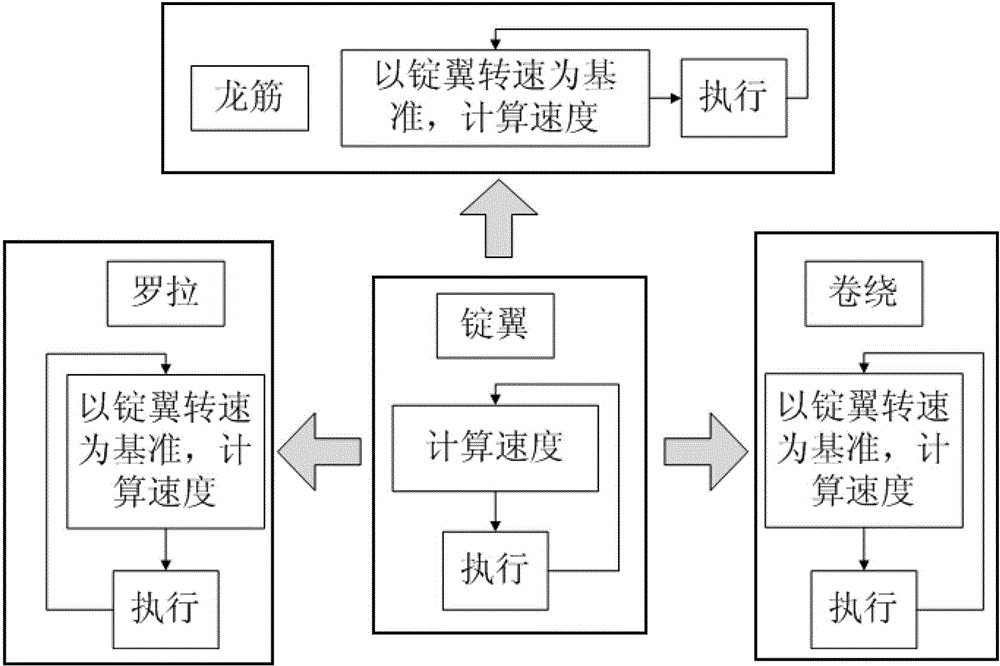

[0039] combine figure 1 As shown, the PLC-free suspended spindle type roving frame servo control system proposed by an embodiment of the present invention includes a flyer motor 11, a roller motor 21, a winding motor 31 and a dragon tendon motor 41; it is electrically connected with the flyer motor 11 and used The first driver 10 used to control the work of the flyer motor 11 is electrically connected to the roller motor 21 and used to control the second driver 20 of the roller motor 21, and is electrically connected to the winding motor 31 and used to control the winding motor 31. The third driver 30 , and the fourth driver 40 electrically connected to the dragon tendon motor 41 and used to control the operation of the dragon tendon motor 41 .

[0040] Further, the servo control system of the non-PLC suspended spindle type roving frame also includes a touch screen 50 communicatively connected with the first driver 10, the second driver 20, the third driver 30 and the fourth d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com