Modularized splice type steel keel structure for veneer decoration and construction method thereof

A construction method and decorative panel technology, applied in the field of building interior decoration, can solve problems such as unheard of success and unseen technical inspiration, achieve fast and reliable hanging requirements, save resources, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

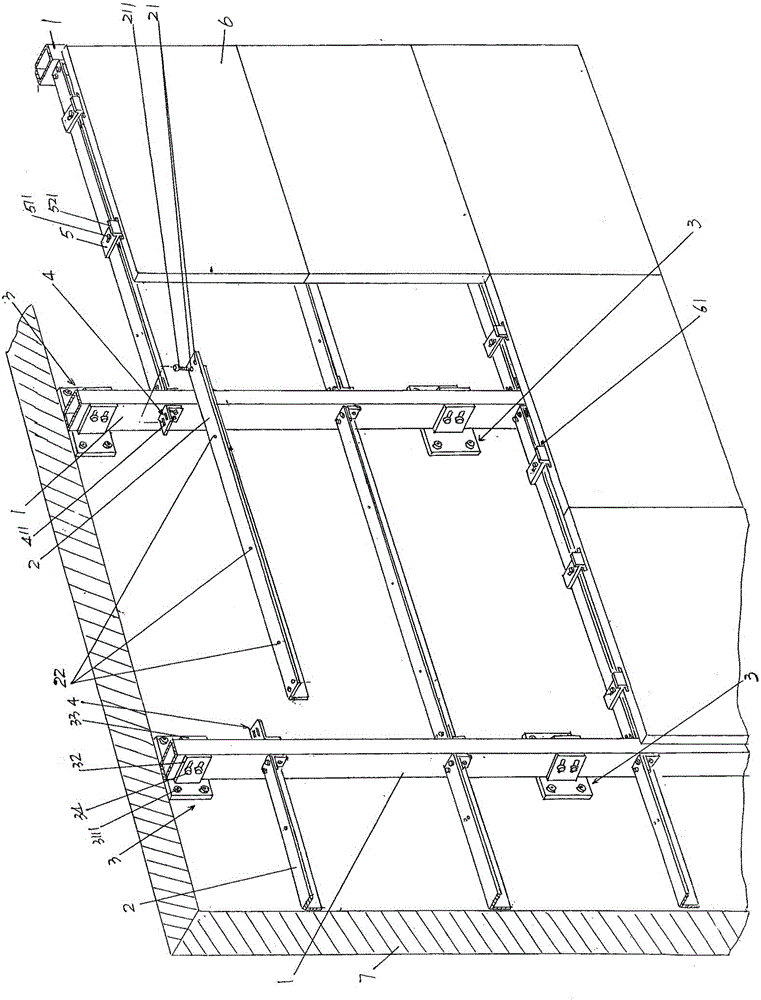

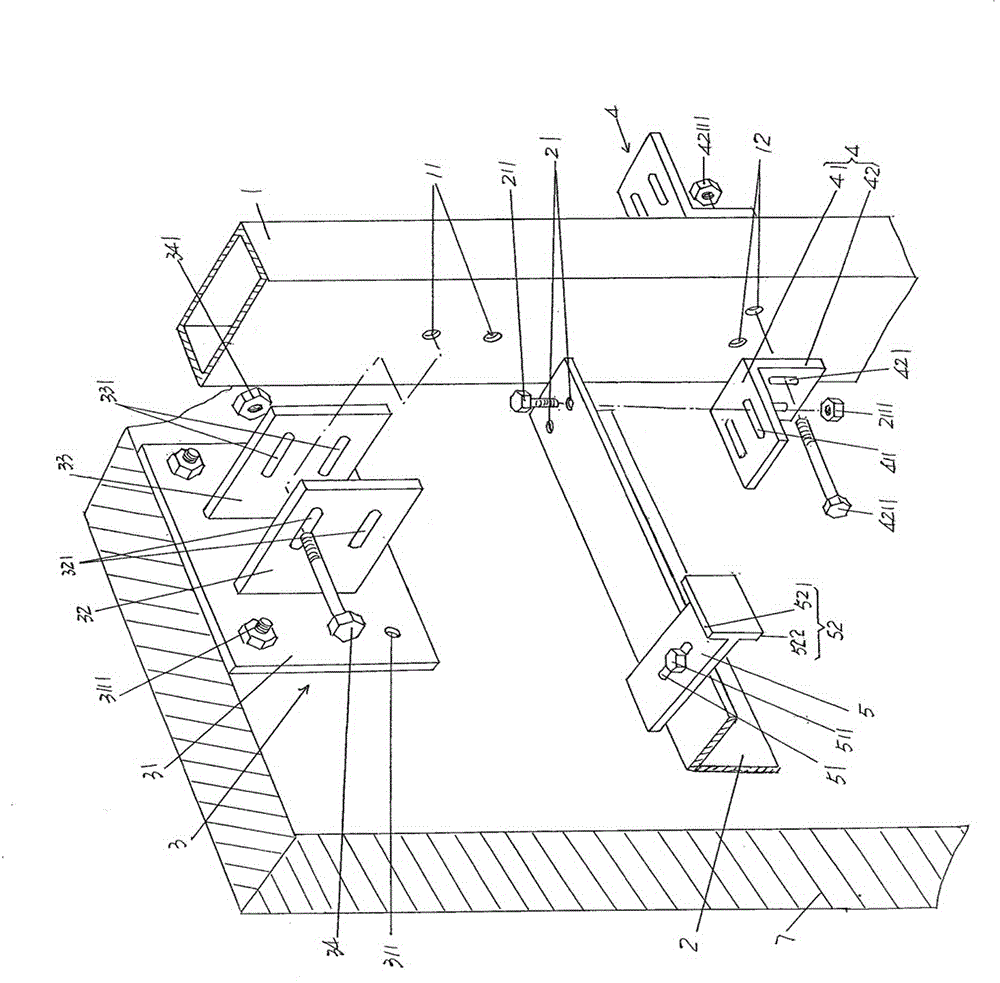

[0028] See figure 1 , the longitudinal keel 1 is given, the longitudinal keel 1 is a hollow rectangular tube with a rectangular cross-sectional shape. 50mm and a thickness of 4mm. On the walls facing each other of the longitudinal keel 1 and along the height direction of the longitudinal keel 1 (also called the height direction as the length direction), several pairs of fixing mechanism connection holes 11 and several pairs of fixed adjustment seat connections are opened at intervals. Holes 12, wherein, the two holes of each pair of fixing mechanism connecting holes 11 are in a corresponding relationship up and down, and the connecting holes 12 of each pair of fixed adjustment seats are in a corresponding relationship between left and right.

[0029] Given the transverse keel 2, the transverse keel 2 is connected horizontally (horizontally) between two adjacent longitudinal keels 1 in the state of use, and is distributed along the height direction of the longitudinal keel 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com