Pipe flow direct-drive power generating device

A power generation device, direct-drive technology, applied in electromechanical devices, wind power generation, engines, etc., can solve the problems of affecting power utilization, not considering wind energy, wind energy loss, etc., to achieve stable output frequency, avoid energy loss, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

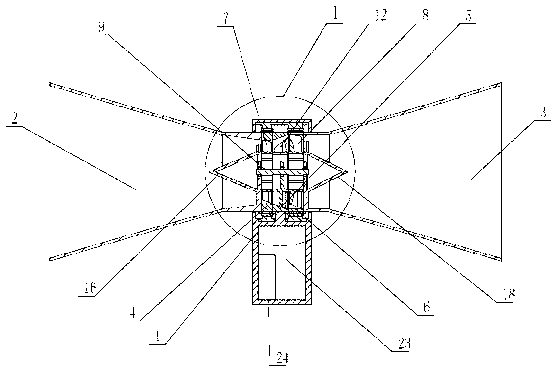

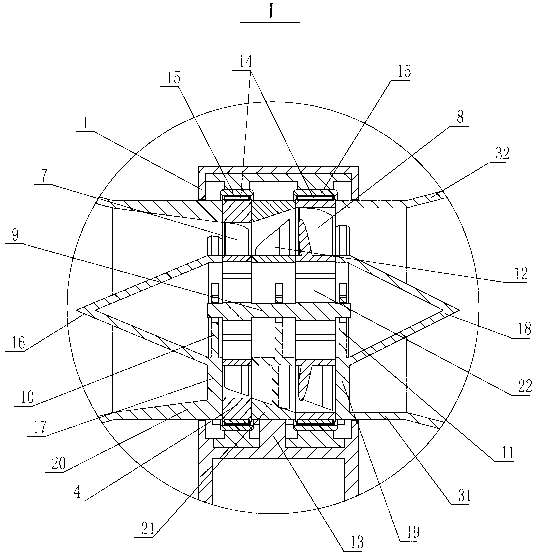

[0019] See figure 1 , figure 2 , the present invention includes a generator housing 1, the two ends of the generator housing 1 are fixedly connected with a shrink tube 2 and a wake tube 3 respectively, the shrink tube 2 and the wake tube 3 communicate in space, and the space between the shrink tube 2 and the wake tube 3 There are at least two stages of rotatable blades, between the shrink tube 2 and the wake tube 3 there are successively a rotor mounting ring 1 4, a guide vane mounting base 5 and a rotor mounting ring 2 6, and the inner wall of the rotor mounting ring 1 4 is fixed with a second The first-stage rotating blade 7, the inner wall of the rotor mounting ring 2 6 is fixedly connected with the second-stage rotating blade 8, the first-stage rotating blade 7 and the second-stage rotating blade 8 are fixedly supported on the suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com