Flexible ball joint suitable for in-orbit application of high-precision mechanism of spacecraft

A high-precision, spacecraft technology, applied in the direction of pivot connection, etc., can solve the problems of increasing the difficulty and cost of processing, complex joint structure, high fatigue requirements of joint materials, etc., and achieve the effect of eliminating gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

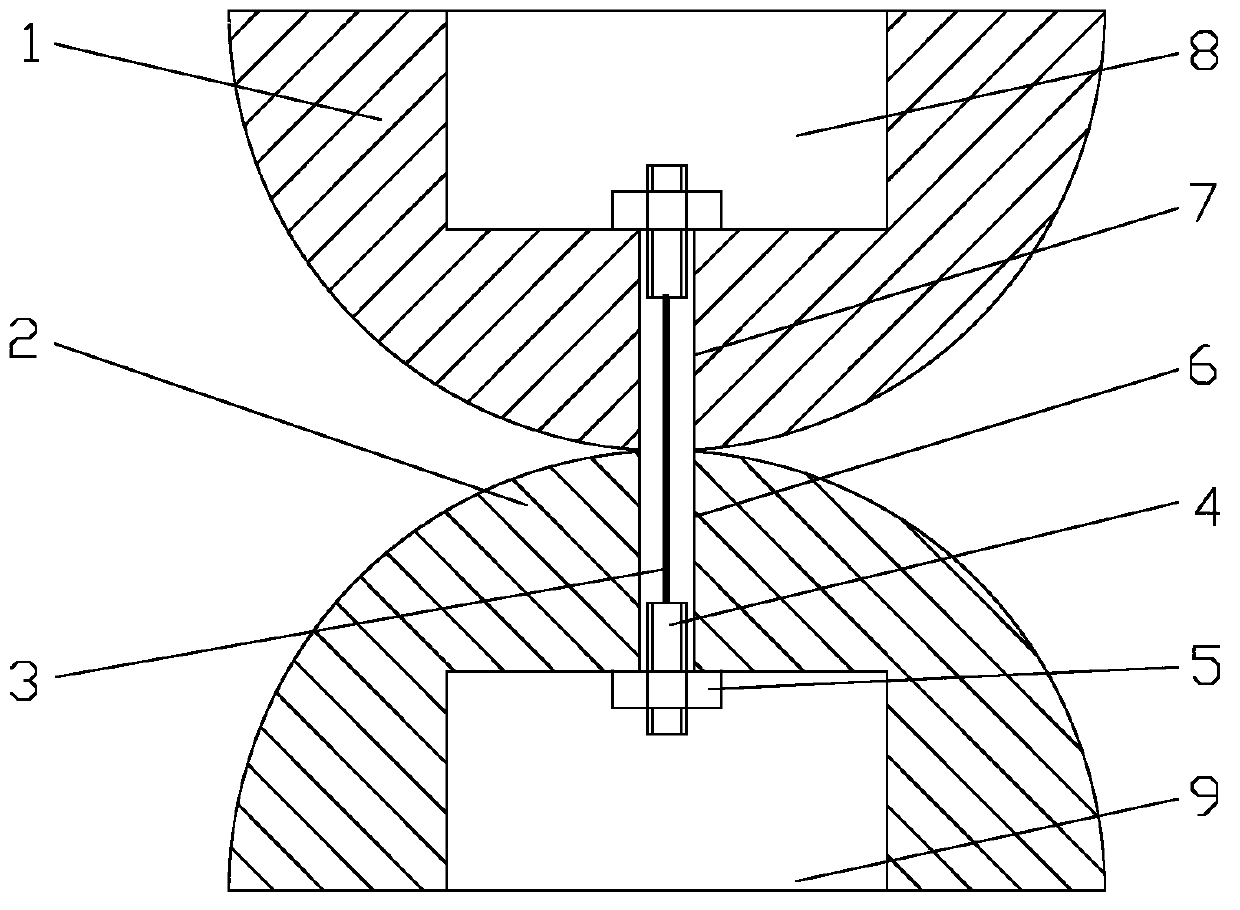

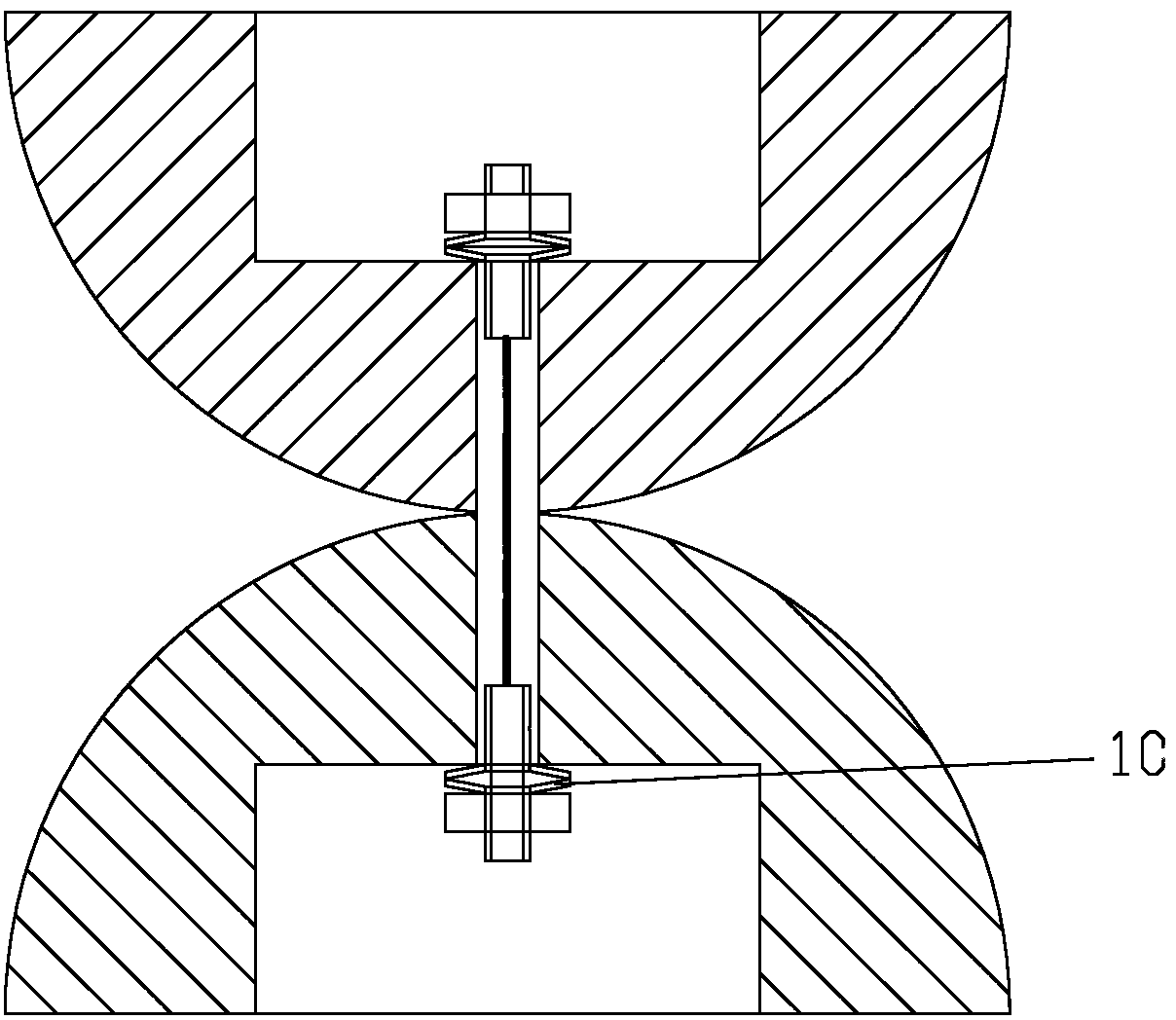

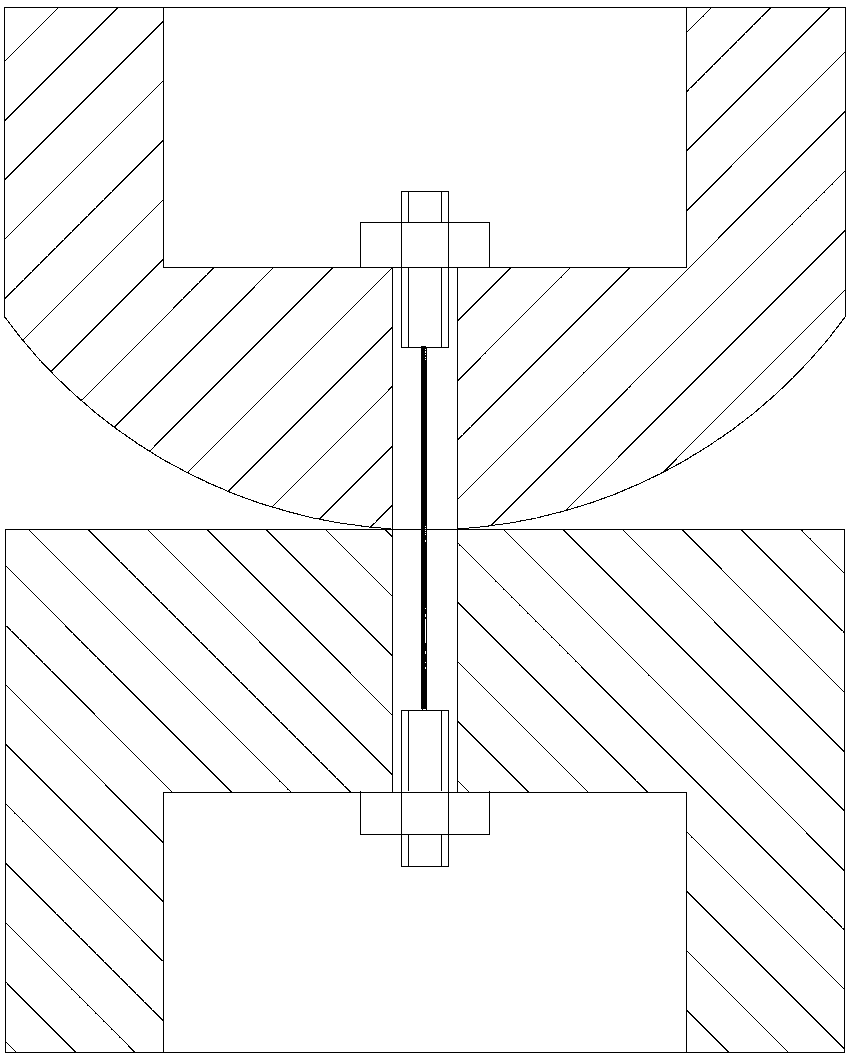

[0017] Such as figure 1 As shown, the present invention provides a flexible ball joint suitable for on-orbit application of spacecraft high-precision mechanisms. The present invention mainly includes an upper spherical body 1, a lower spherical body 2, a tensioning rope 3, a tensioning stud 4 and a locking Nut 5. The spherical body 1 and the spherical body 2 are a part of the sphere, and the upper spherical body 1 has a round hole 7 and a groove 8, and the spherical body 2 has a round hole 6 and a groove 9, and the tension rope 3 passes through the round hole 6 and the round hole. Hole 7. The spherical body 1 and the spherical body 2 are connected by a tensioning rope 3, a tensioning stud 4 and a lock nut 5, and the spherical surface of the contact part of the spherical body 1 and the spherical body 2 constitutes a ball joint. The movement of the ball joint is constrained by the contact spherical surfaces of the upper spherical body 1 and the lower spherical body 2 and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com