A heating device to ensure the surface bonding rate

A heating device and bonding rate technology, which is applied to lighting and heating equipment, heat exchange equipment, heat exchanger shells, etc. , the problem of low fit rate, etc., to achieve the effect of simple structure, reasonable design, and guaranteed fit rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

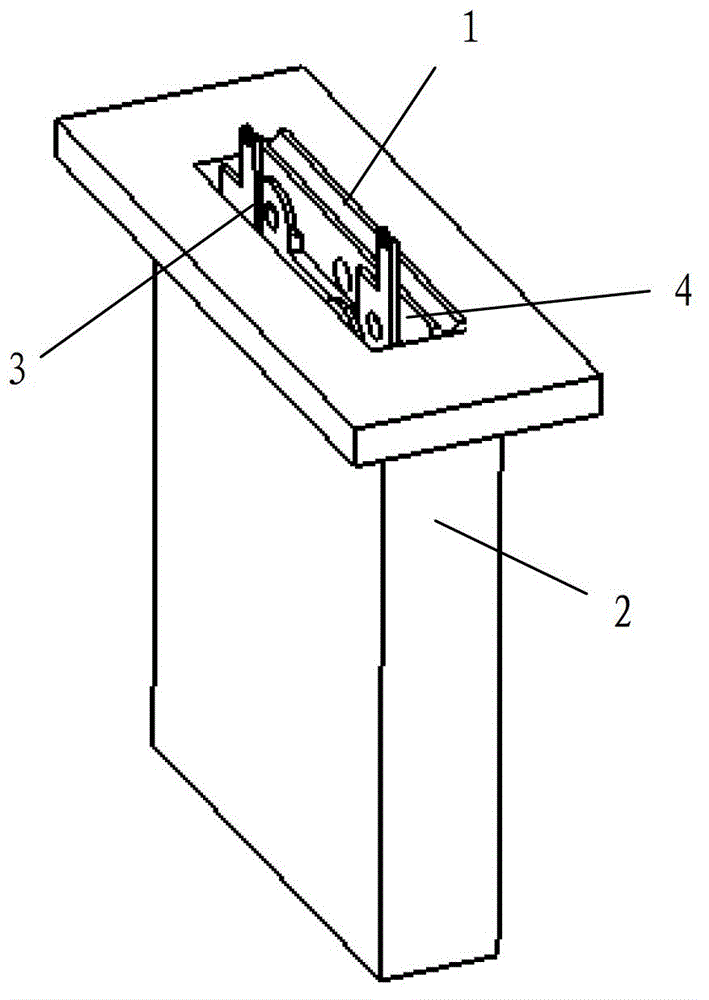

[0024] like figure 1 , 4 As shown, a heating device that ensures the surface bonding rate includes a radiator 2, a heating unit 3 installed in the radiator tank 4, and a wedge plate 1 arranged between the surface of the heating unit 3 and the wall of the radiator tank.

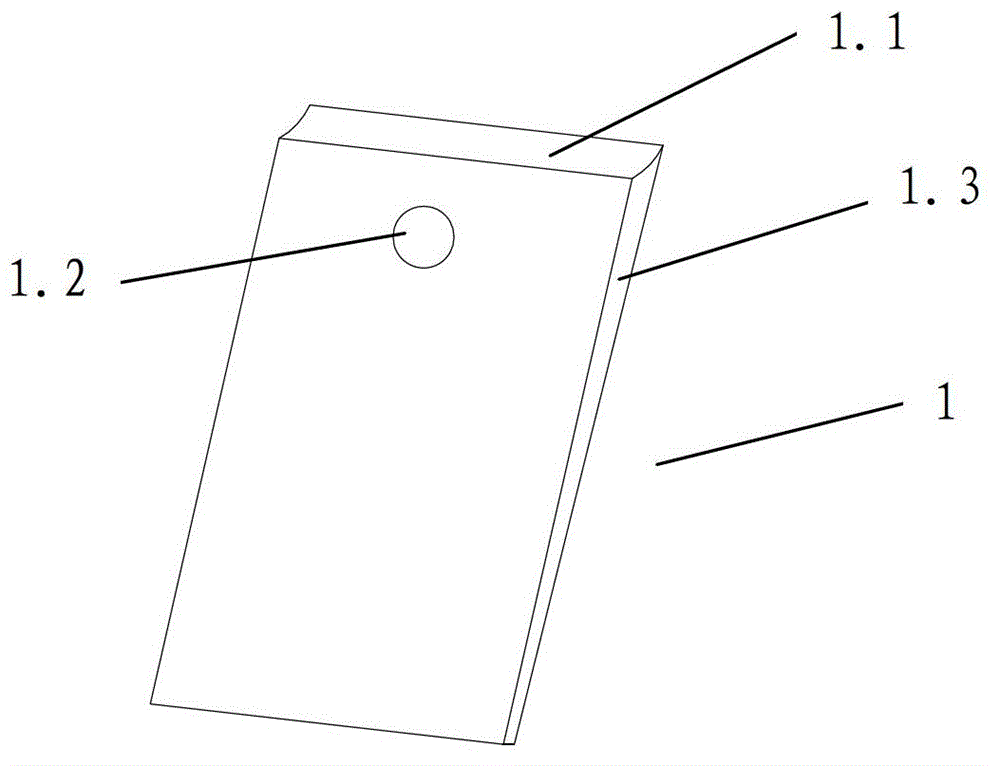

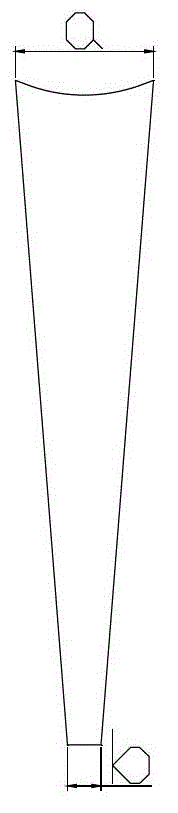

[0025] like figure 2 , 3 , 5, 6, and 7, the key point of the present invention is the design of the wedge plate and its matching structure with the heating unit and the radiator groove. In order to ensure the tight fit between the surface of the heating unit and the wall of the radiator groove, the draft angle 1.3 of the side surface of the wedge plate is the same as the draft angle 4.1 of the side surface of the radiator groove wall, and the width a of the upper surface of the wedge plate 1 is equal to The sum of the upper surface width c of the heating unit 3 is greater than the upper surface width e of the radiator groove 4, the sum of the lower surface width b of the wedge plate 1 and the lower surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com