Identification method for abnormal state of three-phase asynchronous motor at industrial site

A three-phase asynchronous, abnormal state technology, applied in the direction of motor generator testing, etc., can solve the problems of comprehensive utilization, no data, high data acquisition requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

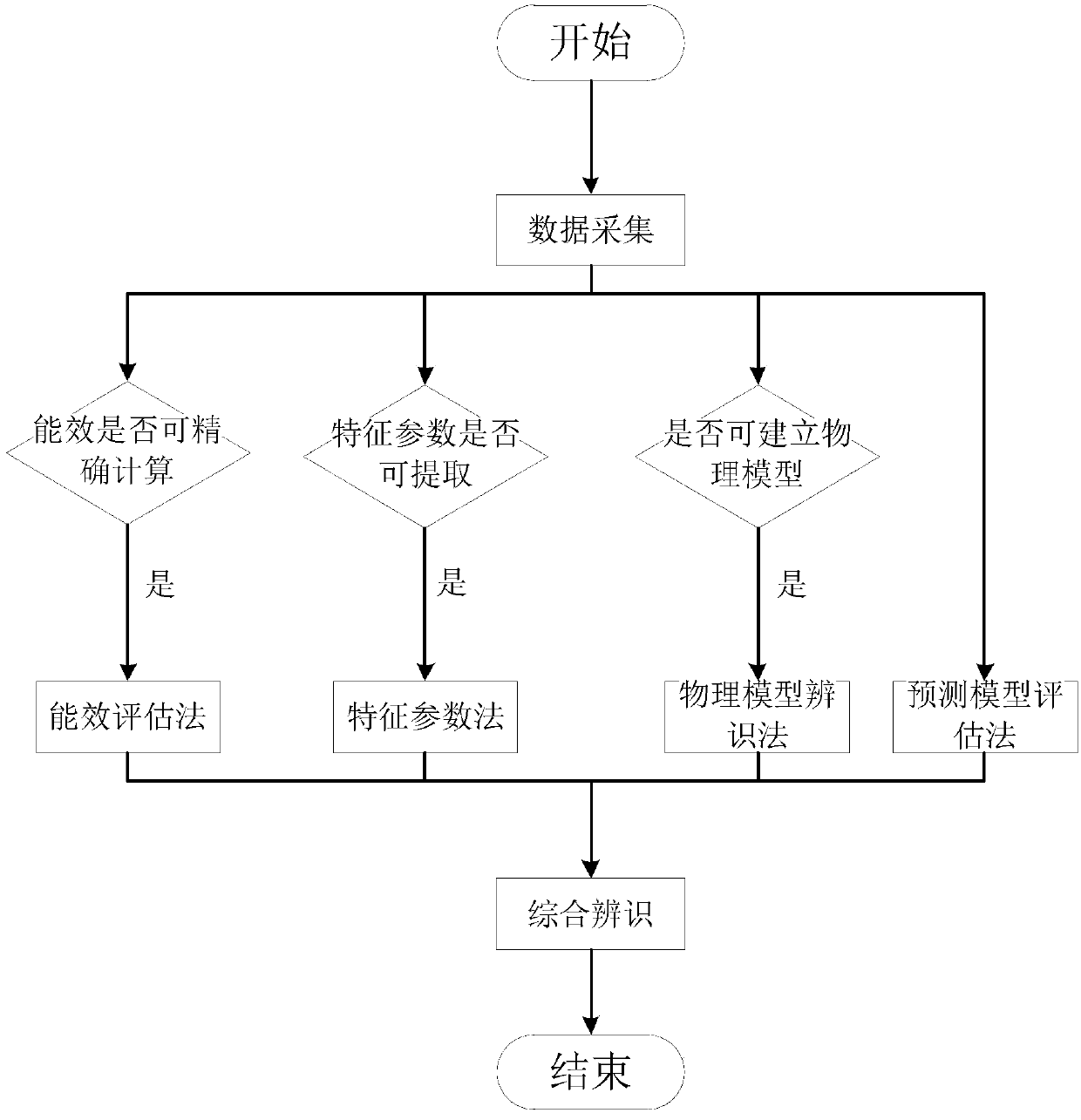

Method used

Image

Examples

Embodiment 1

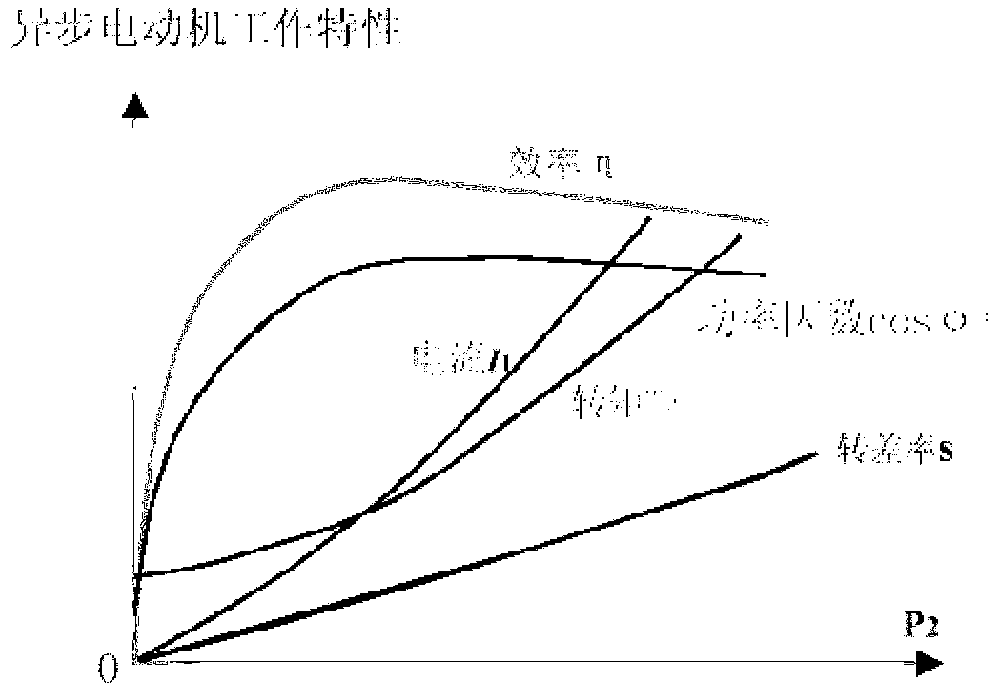

[0029] The output power P of the three-phase asynchronous motor can be directly measured online at the industrial site out or output power P out =f 1 (λ 1 ,λ 2 ...λ n ) parameter λ 1 ,λ 2 ...λ n , then select energy efficiency evaluation for abnormal state identification:

[0030] Measure the applied voltage, frequency, load rate, output torque, motor actual speed and input power, etc., according to In the formula, η is the online energy efficiency, P out is the output power, P in is the input power, n is the actual speed of the motor, and T is the output torque. The calculated online energy efficiency is 0.86. In this embodiment, when the applied voltage is 220v, the frequency is 50Hz, and the load rate of the motor is 0.6, according to the load rate-efficiency curve of the motor, the theoretical energy effect during normal operation is 0.88; the threshold value is set to 5 %, the deviation between online energy efficiency and theoretical energy efficiency It me...

Embodiment 2

[0032] It can directly measure the characteristic quantities that characterize the operation of three-phase asynchronous motors: power factor and efficiency, and select characteristic parameters to identify abnormal states:

[0033] When the applied voltage is 220v and the frequency is 50Hz, the load rate is 0.6, and other working conditions remain unchanged. The power factor is measured 30 times during normal operation, and the calculated average value is 0.84, and the standard deviation is 0.025. The power factor obtained from a certain measurement is 0.86, according to the double deviation criterion, |0.86-0.84|=0.02<0.025×2, indicating that the motor is running normally and there is no abnormality; the power factor obtained from a certain measurement is 0.78, according to the double deviation Criterion, 0.025×2<|0.78-0.84|=0.06<0.025×3, indicating that there is an abnormality in the motor, but no danger has occurred; the power factor obtained from a certain measurement is 0...

Embodiment 3

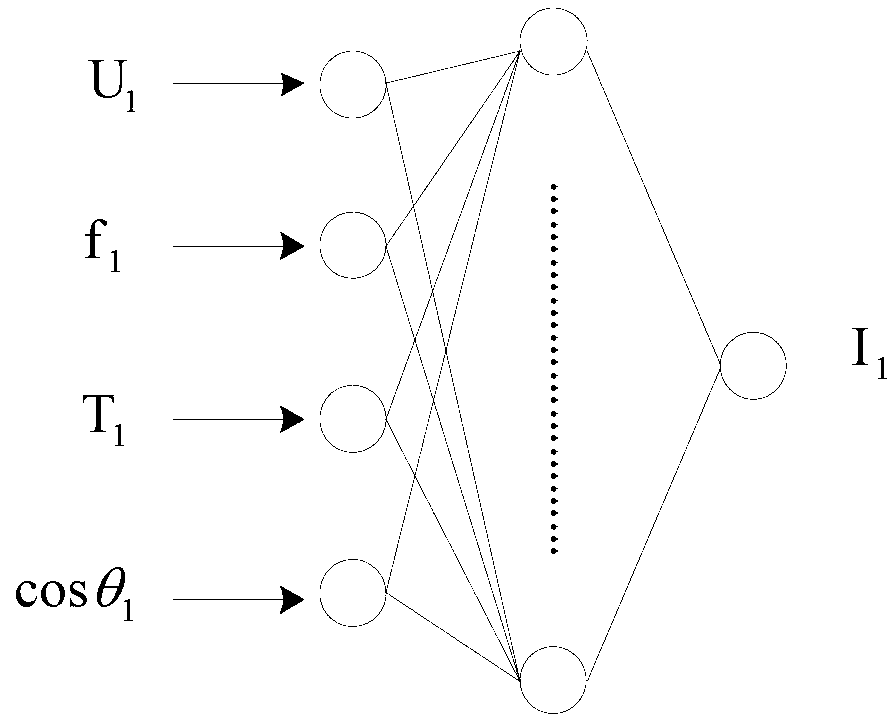

[0035] If the physical model can be established based on the measured values of the three-phase asynchronous motor, the physical model identification is selected for abnormal state identification:

[0036] Keep the applied voltage at 220v and the frequency at 50Hz. According to the historical data during normal operation, the load rate-power factor curve (β-cosθ 1 ) for cosθ 1 =0.3804+0.2001β+0.42β 2 , and according to the actual measured data, the load rate-power factor curve (β-cosθ 1 ) for cosθ 1 =0.3789+0.2092β+0.4184β 2 , the two model errors are Δ=|-0.0015+0.0091β-0.0016β 2 |≤0.0015+0.0091+0.0016=0.0122 (when β≤1), it can be seen that the changes of the polynomial coefficients before and after are small, indicating that the motor is running normally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com