Pressed-type switch with kick function

A sudden jump and functional technology, applied in the direction of electric switches, electrical components, circuits, etc., can solve the problems of complex structure, poor operation flexibility, and short service life of push switches, so as to ensure stability, force balance, and avoid wear and tear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

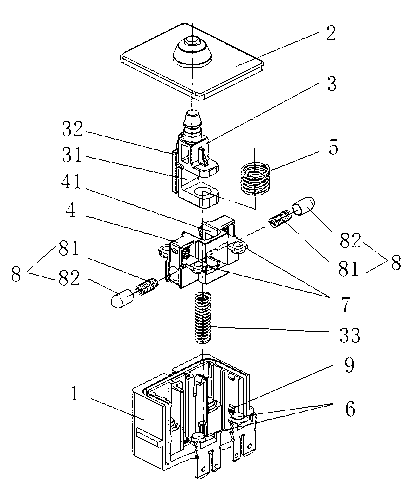

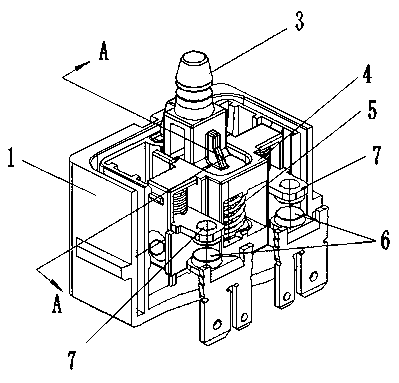

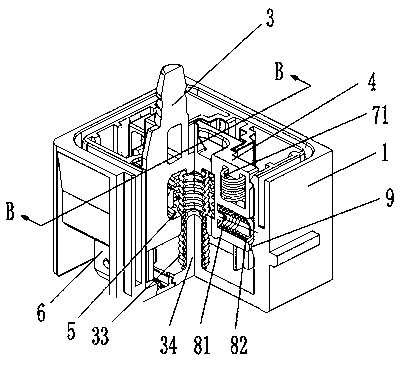

[0029] see Figure 1-4 , a push switch with kick function of the present invention, comprising a housing 1, a button assembly slidably installed inside the housing 1, an end cover 2 is provided at the end of the button assembly, and a The contact assembly in the housing 1, the contact assembly includes a moving contact part driven by the button assembly and a static contact part fixed relative to the housing 1, and the static contact part includes A static contact 6 with two static contacts is formed on the housing, and the moving contact part includes a moving contact 7 and a moving contact frame 4 for supporting the moving contact; Sliding down or upward drives the moving contact part to contact or separate from the static contact 6, and a jumping structure is set between the moving contact frame 4 and the housing 1, and the jumping structure includes a The bump 9 on the housing 1, and the jump assembly arranged on the moving contact frame 4 and matched with the bump 9, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com