Composite insulator lifting frame

A technology of composite insulators and hoisting frames, which is applied to overhead lines/cable equipment, etc., can solve the problems of time-consuming unroping, insufficient hoisting, damage to insulators, etc., to achieve the effect of protection from damage, easy installation at high altitude, and simple processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

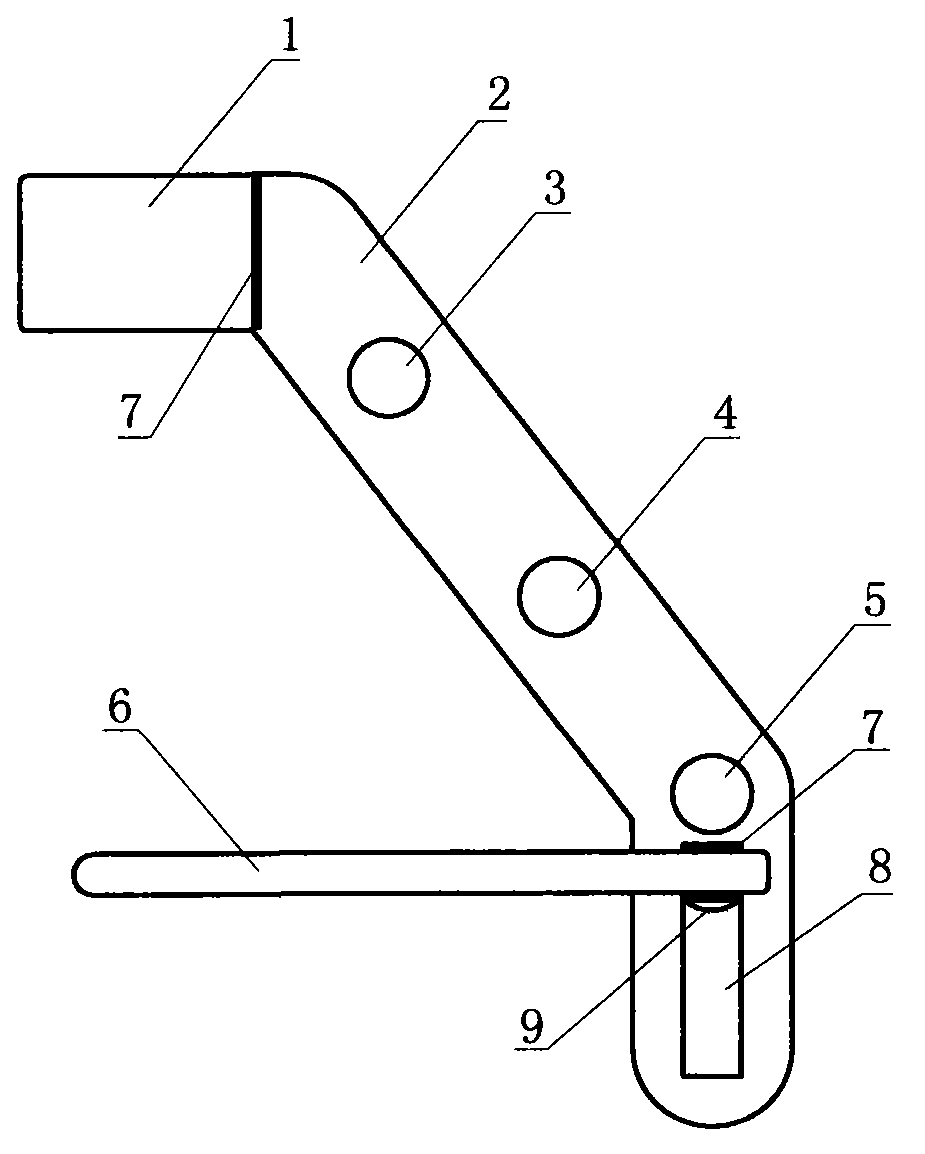

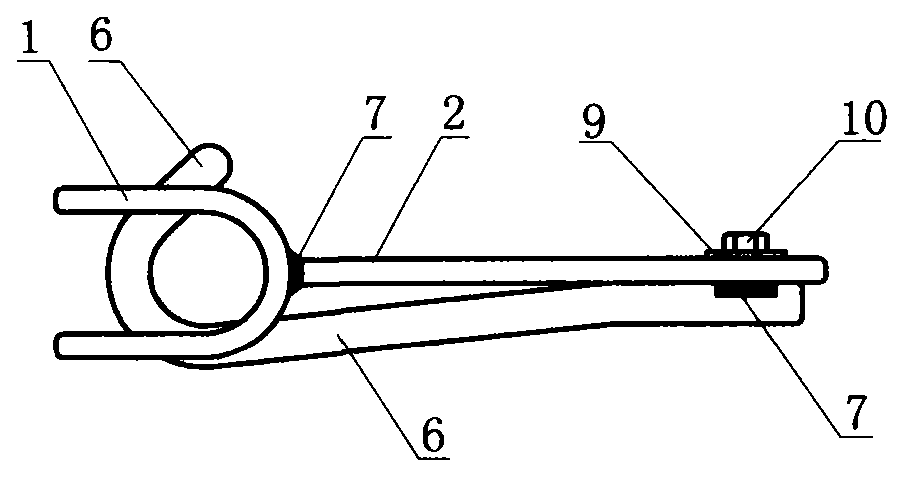

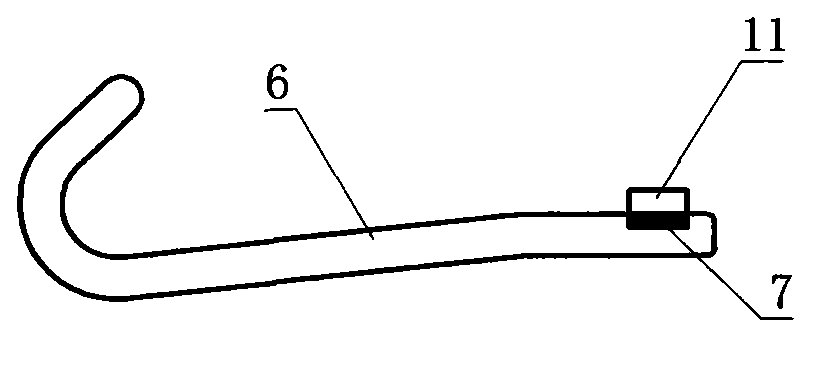

[0024] attached figure 1 It is a structural schematic diagram of Embodiment 1 of the present invention, with figure 2 is attached figure 1 top view, with image 3 It is a schematic diagram of the connection between the waist hook (6) and the slide block (11), with Figure 4 is attached image 3 The top view of the composite insulator; the composite insulator lifting frame is composed of a U-shaped fork, a connecting plate, a slider, and a waist hook. The U-shaped fork (1) is welded to the connecting plate (2), and there is a lifting hole (5) on the connecting plate (2). And slide block adjustment hole (8), square slide block (11) is housed in slide block adjustment hole (8), is welded with waist hook (6) on slide block (11), has screw hole (11) on slide block (11) 12), spacer (9) and locking screw (10), loosen the screw (10) and slide the slider (11), the height of the hook between waist joints (6) can be adjusted to suit different types of composite insulators; Pass the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com