A molding strip for furniture

A modeling and furniture technology, applied to furniture parts, household utensils, furniture accessories, etc., can solve the problems of limited modeling effect, limited buffer capacity, waste of resources, etc., and achieve the effects of concealment, protection against collisions, and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be specifically introduced below in conjunction with the drawings and specific embodiments.

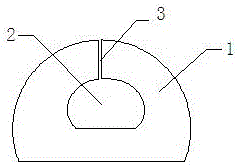

[0014] figure 1 Is a cross-sectional view of an embodiment of the present invention, figure 2 It is a front view of an embodiment of the present invention.

[0015] Such as figure 1 with figure 2 Shown: a shape strip for furniture, wherein the shape strip is a strip with a hollow inside, and its cross-sectional shape is: the bottom surface is a flat surface, and the bottom surface is connected to an arc surface, and the arc The middle section of the shaped surface communicates with the hollow part 2 to form a through seam 3. The cross-sectional shape of the hollow portion 2 can be the same as the overall cross-sectional shape of the molding strip. And in this embodiment, the material of the shaped strip is EVA foamed plastic.

[0016] The present invention is simple in structure, environmentally friendly and easy to manufacture, non-toxic, tasteless an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com