A side insert of a high-pressure roller mill roller sleeve and its replacement method

A high-pressure roller mill and insert technology, applied in bonding methods, grain treatment, adhesives, etc., can solve the problem of increased equipment maintenance cycle and cost, large wear of roller sleeves and side baffles, and shortened service life of roller sleeves, etc. problems, to achieve the effect of reducing maintenance time and maintenance costs, improving equipment operation rate, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

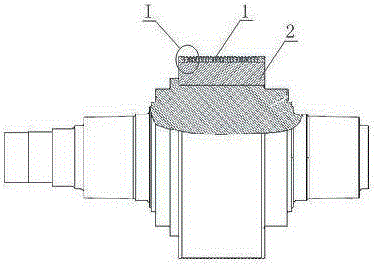

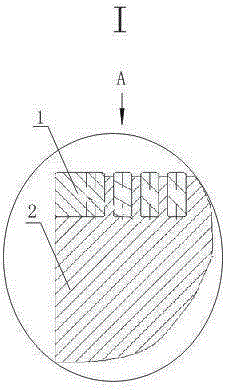

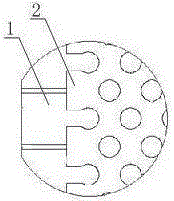

[0022] Such as figure 1 , 2 As shown in , 3, a side insert of a high-pressure roller mill roll cover, the side insert 1 is in the shape of a circle, and the side insert 1 is embedded in the outer surface of the roll cover 2 on both sides along the circumferential direction. In the annular groove, the annular groove is adapted to the radial cross-sectional shape of the side insert, and the side insert 1 and the annular groove are embedded and connected by a clearance fit; the side insert 1 is It is a circular structure composed of several inserts made of high-strength and wear-resistant hard alloy. Adjacent inserts are tightly bonded by adhesives. The adhesive loses its adhesion at 180-200°C. connection.

[0023] Such as Figure 4 As shown, a structure of the insert is as follows: it is integrally composed of a support part 3 and a protecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com