Tubular product bending method

A pipe and bending technology, which is applied in the field of pipe bending, can solve the problems of increasing mandrel manufacturing and use costs, high mold design and manufacturing costs, and difficulty in controlling pipe wrinkling, etc., to achieve reduced scratches, low use and maintenance costs, The effect of suppressing the possibility of wrinkling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

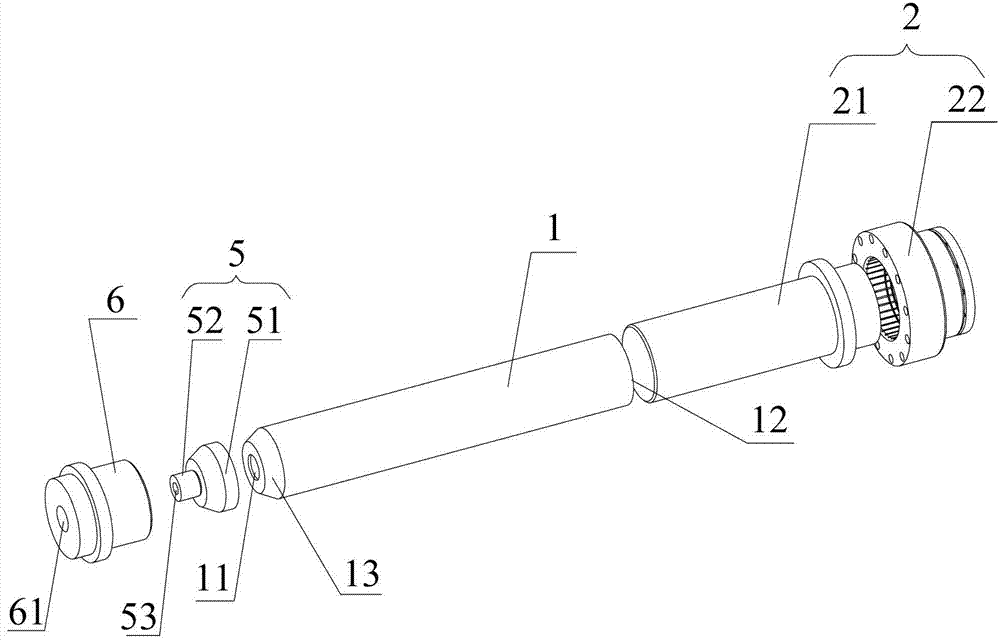

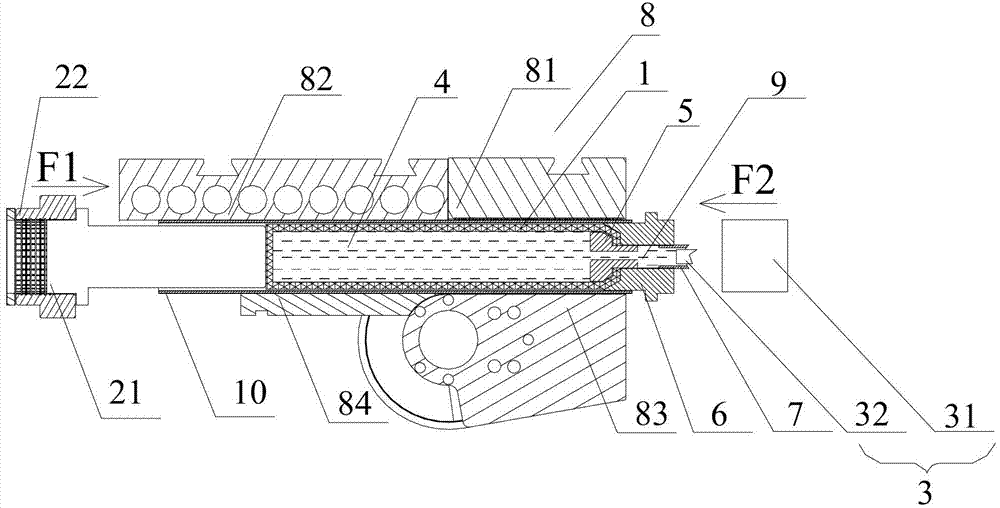

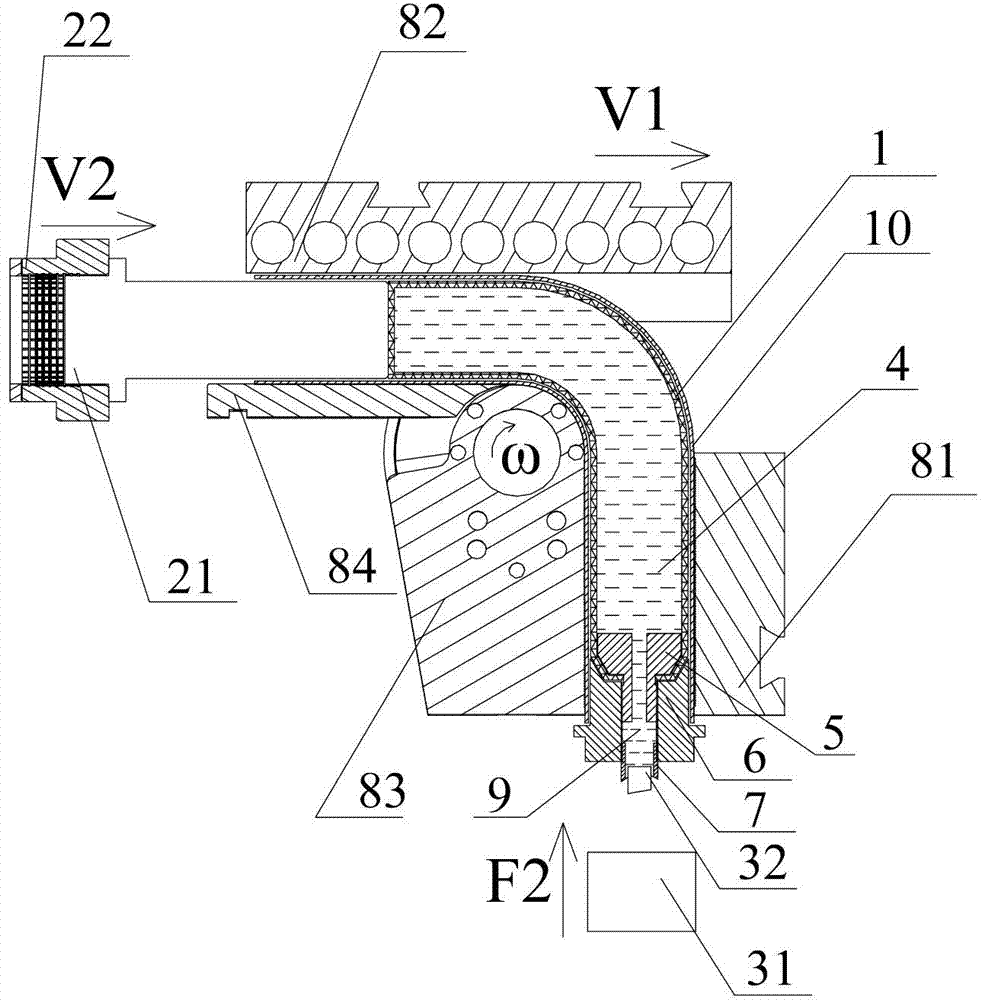

[0041] Step 1: Customize a cylindrical rubber bag 1 according to the inner diameter of the pipe 10 (for example, the inner diameter is greater than or equal to 20 mm). There is a certain gap between the outer wall of the rubber bag 1 and the inner wall of the pipe 10, and the diameter of the rubber bag 1 is 2 mm to 3 mm smaller than the inner diameter of the pipe 10. The rubber bag 1 has a thickness of 3 mm to 5 mm, and the head of the rubber bag 1 is in the shape of a truncated cone, and the end face of the head is perforated to form a through hole 11 through the inner cavity of the rubber bag 1; the cone angle of the head of the rubber bag 1 is 10°- 30°, the height of the round platform is 20mm-50mm, the end face of the head is perforated, and the aperture is 5mm-50mm smaller than the diameter of the end face; in this embodiment, according to the inner diameter of the pipe 10 of 68mm, a cylindrical rubber bag 1 is customized, and the diameter of the rubber bag 1 is 66mm. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com