A construction method of multi-steel beam-concrete composite ultra-flat beam and flat beam

A technology of concrete and steel beams, which is applied in the direction of long-strip structural components for load-bearing, anti-seismic, building components, etc., and can solve the problems of long construction period, complex construction, and small steel distribution ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

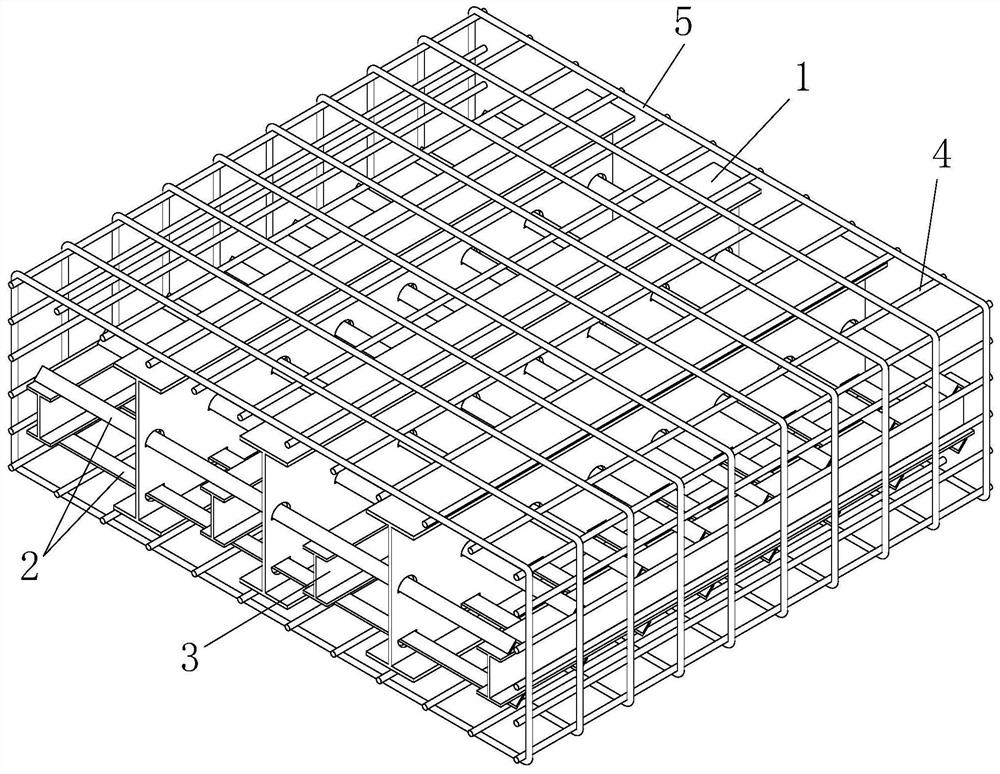

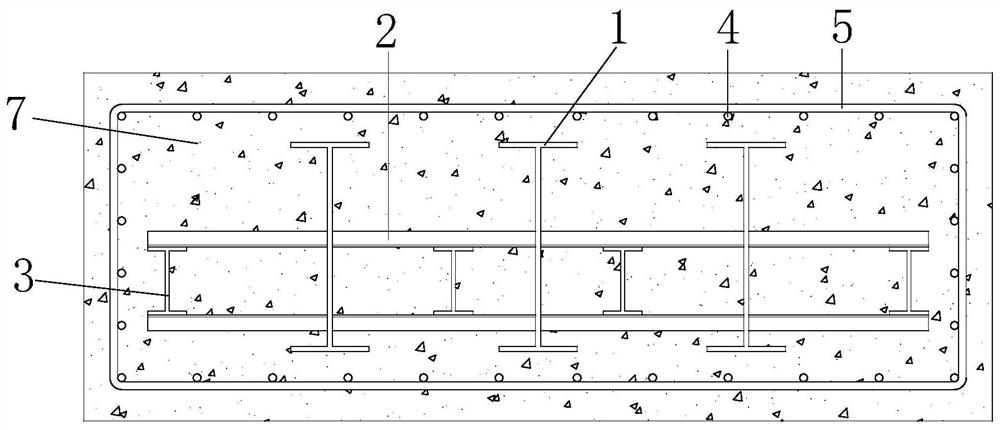

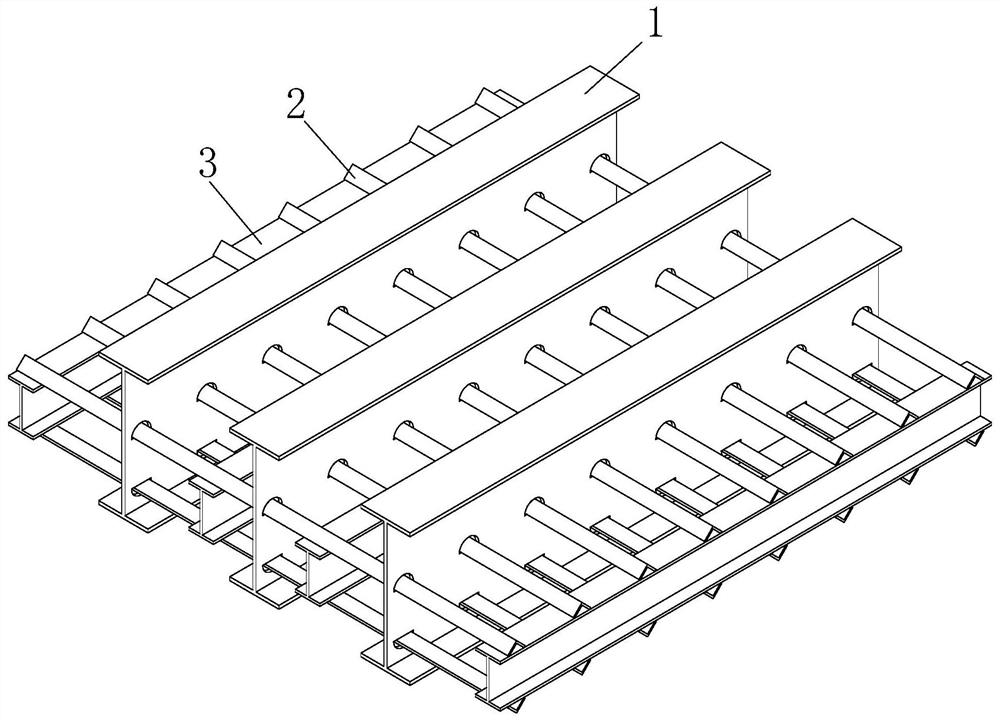

[0032] A kind of multi-steel girder-concrete composite ultra-flat beam of the present invention, as figure 1 , figure 2 and image 3 As shown, it includes a reinforcement cage, and one or more parallel and opposite main steel beams 1 are arranged in the steel cage, and two rows of reserved holes 6 are opened on each main steel beam 1, and a plurality of angle steels 2 are also included, and each angle steel 2 through the reserved hole 6 to connect a plurality of main steel beams 1, and connect the secondary steel beams 3 between two rows of angle steels 2, and fill the reinforcement cage with concrete 7.

[0033] Such as Figure 4 As shown, the centerlines of the two rows of reserved holes 6 are not higher than the neutral axis of the section of the main steel beam 1 .

[0034] Such as Figure 5 As shown, each reserved hole 6 is semicir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com