Contactless guide device

A guiding device and non-contact technology, applied in feeding devices, metal processing machinery parts, metal processing equipment, etc., can solve problems such as difficult to achieve overall optimization, and achieve the effect of improving accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The content of the present invention will be further described below in conjunction with the accompanying drawings and embodiments of the description.

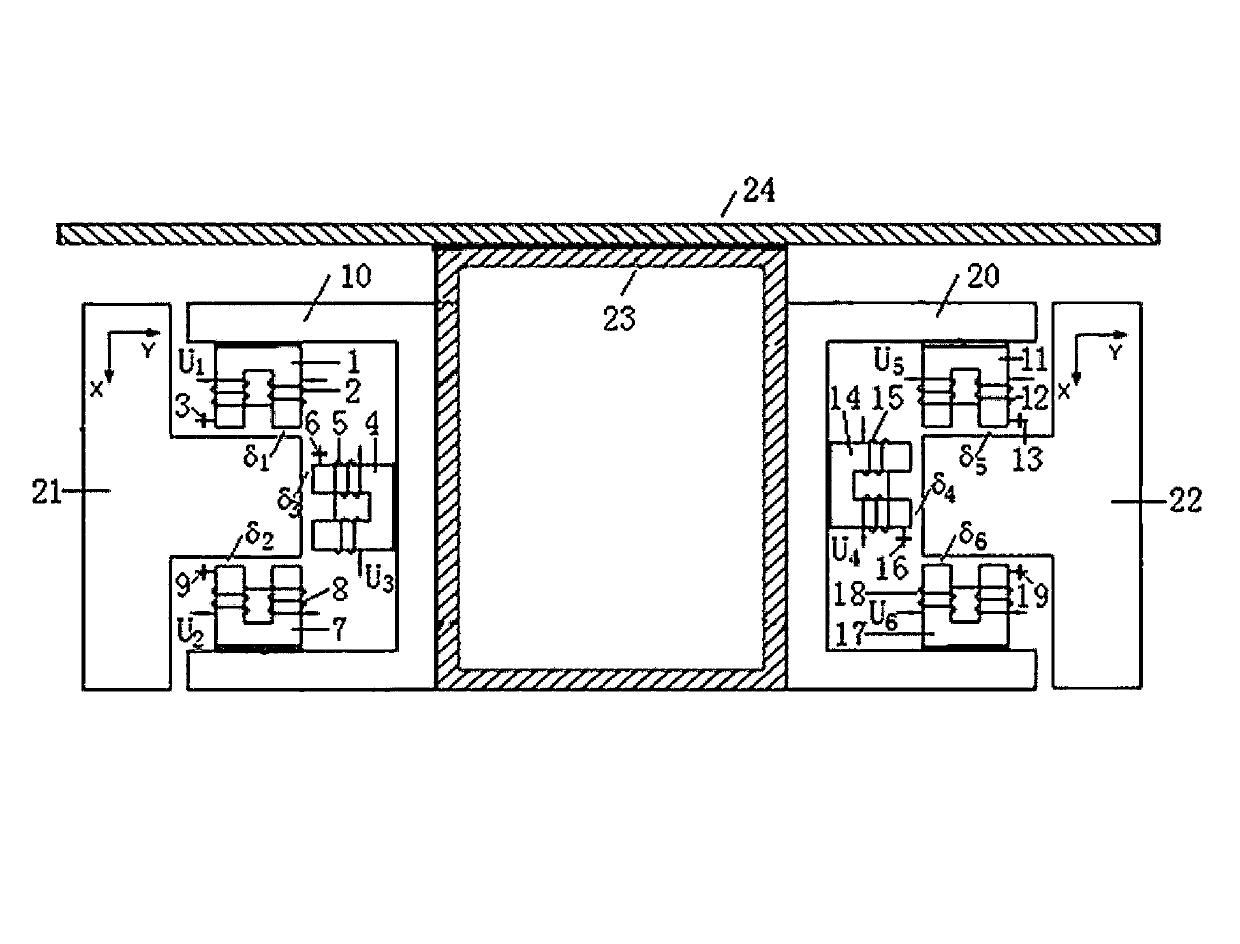

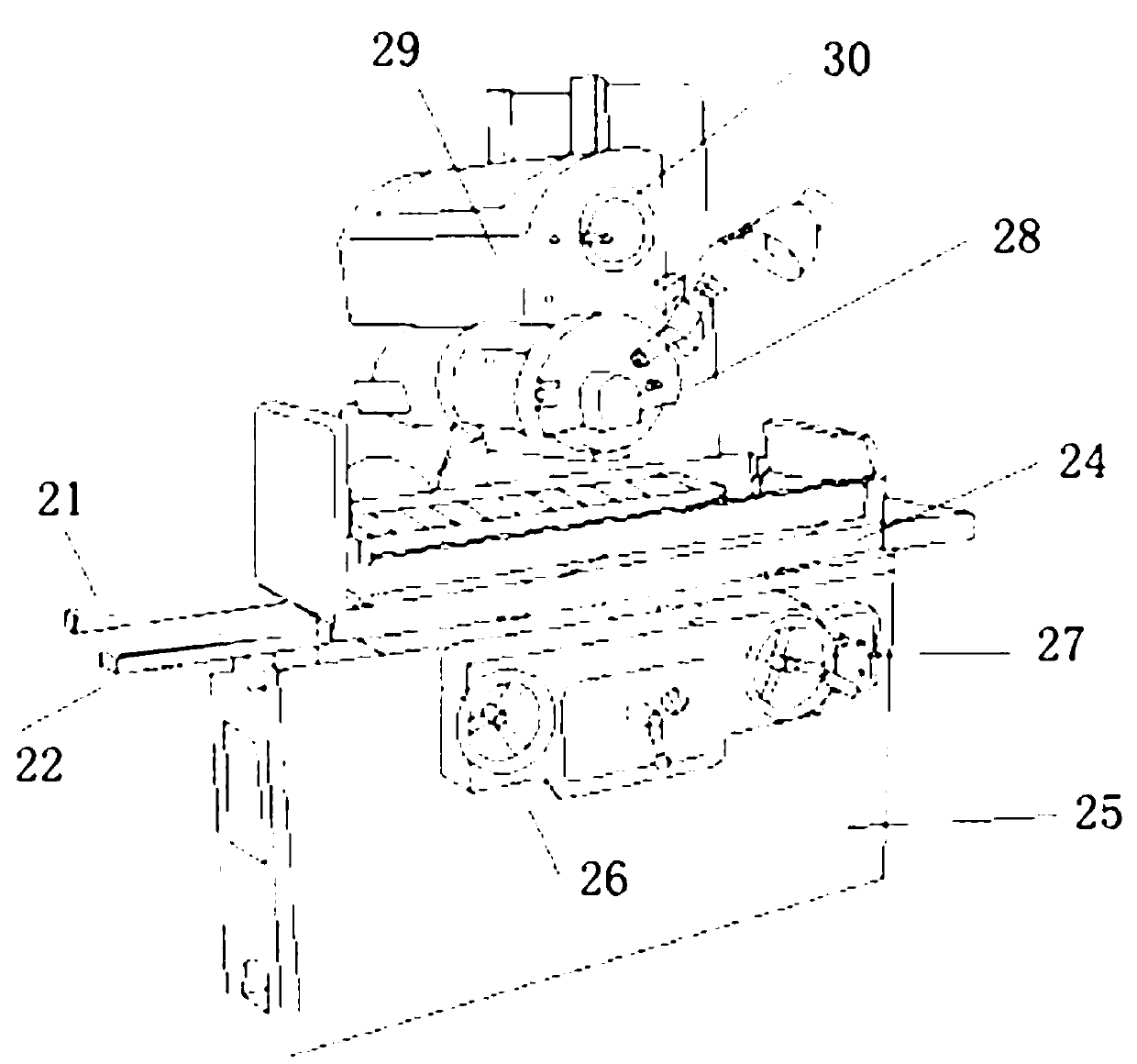

[0024] One embodiment of the present invention is a machine tool motion platform, its basic structure is as follows figure 1 As shown, it includes an organic machine tool motion platform, a moving part 23, a workbench 24, a first U-shaped electromagnetic force device U1, a second U-shaped electromagnetic force device U2, a third U-shaped electromagnetic force device U3, and a fourth U-shaped electromagnetic force device. Device U4, the fifth U-shaped electromagnetic force device U5, the sixth U-shaped electromagnetic force device U6, the first T-shaped magnetic guide rail 21, the second T-shaped magnetic guide rail 22, the first support 10, the second support 20, wherein the first The support 10 and the second support 20 are all grooved structures, and the first U-shaped electromagnetic force device U1, the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com