Large-scale surface throttling self-compensating ultra-precise liquid change table

A self-compensating, ultra-precise technology, applied to optical surface grinders, bearings, shafts, etc., can solve problems such as limitations, difficult design and development of ultra-precision hydrostatic turntables, and reduction of manufacturing accuracy and efficiency of large-scale space optical mirrors. , to achieve the effect of improving the rotation accuracy and increasing the axial direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

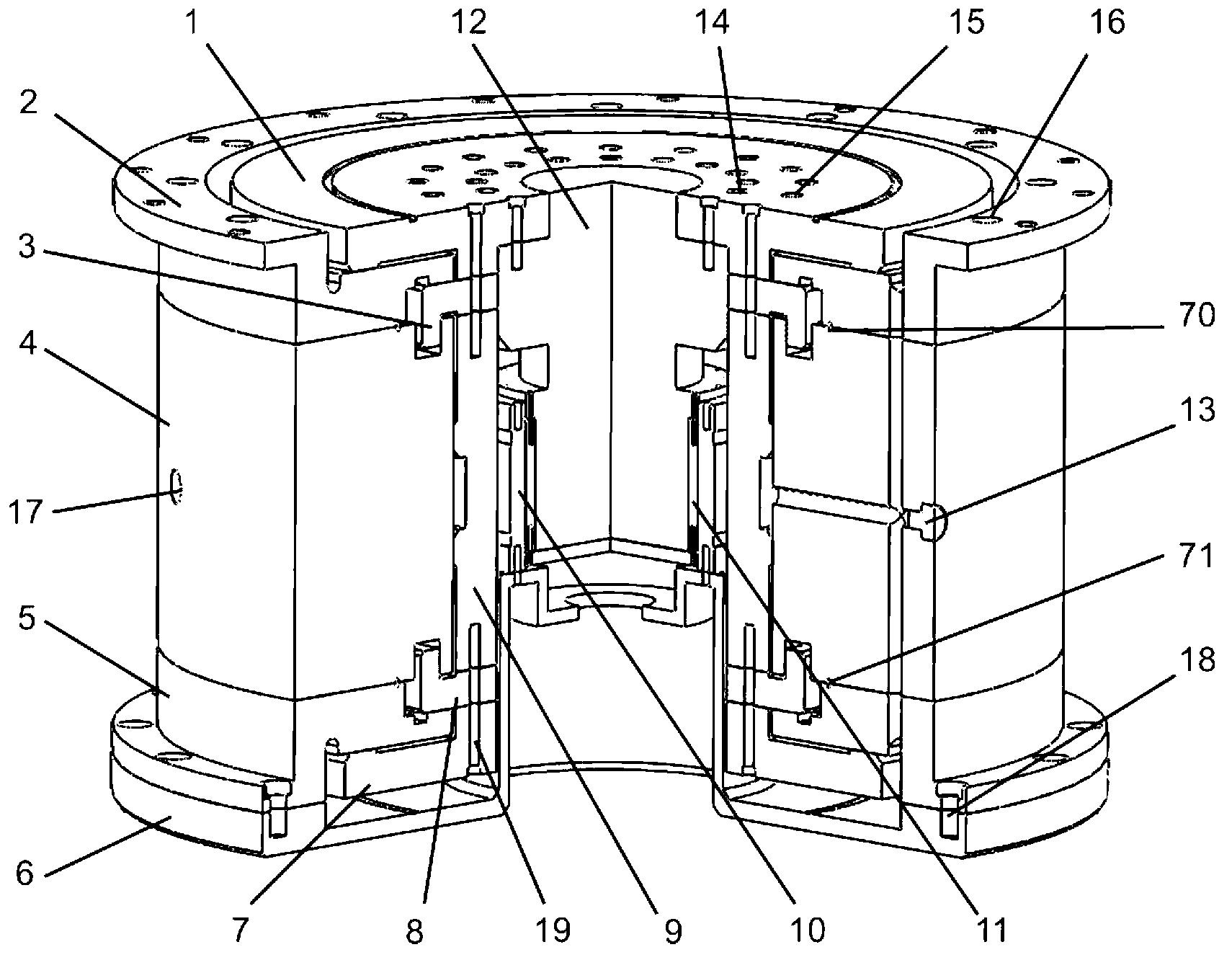

[0036] A specific embodiment of a large-scale surface throttling self-compensating ultra-precision hydrostatic turntable of the present invention will be described below with reference to the accompanying drawings.

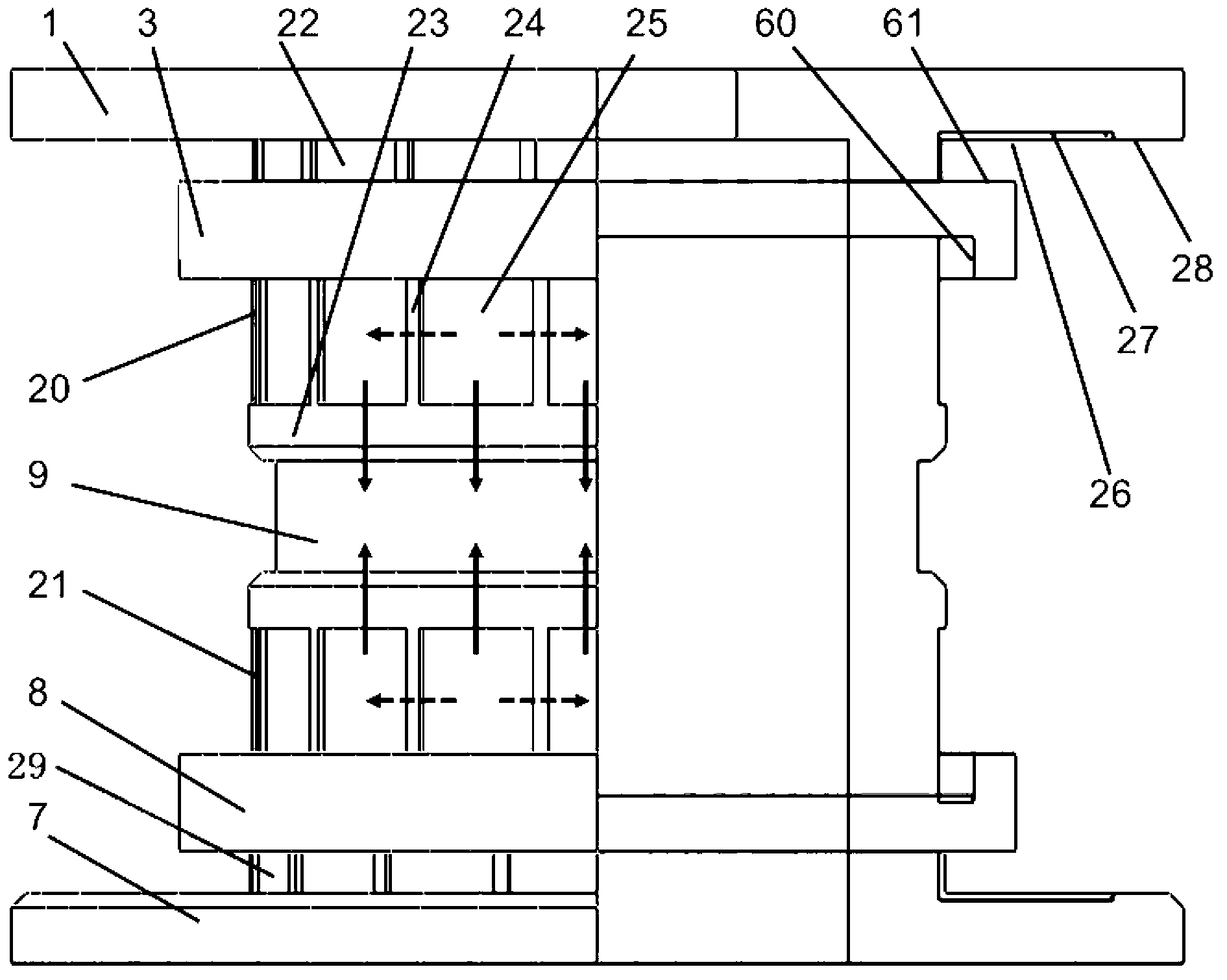

[0037] A large-scale surface throttling self-compensating ultra-precision hydrostatic turntable of the present invention includes a stator system, a rotor system, and a pressure fluid supply and distribution system. The rotor system is located at the center of the entire ultra-precision hydrostatic turntable, the stator system is surrounded by the rotor system, and the pressure fluid supply and distribution system is located between the stator system and the rotor system.

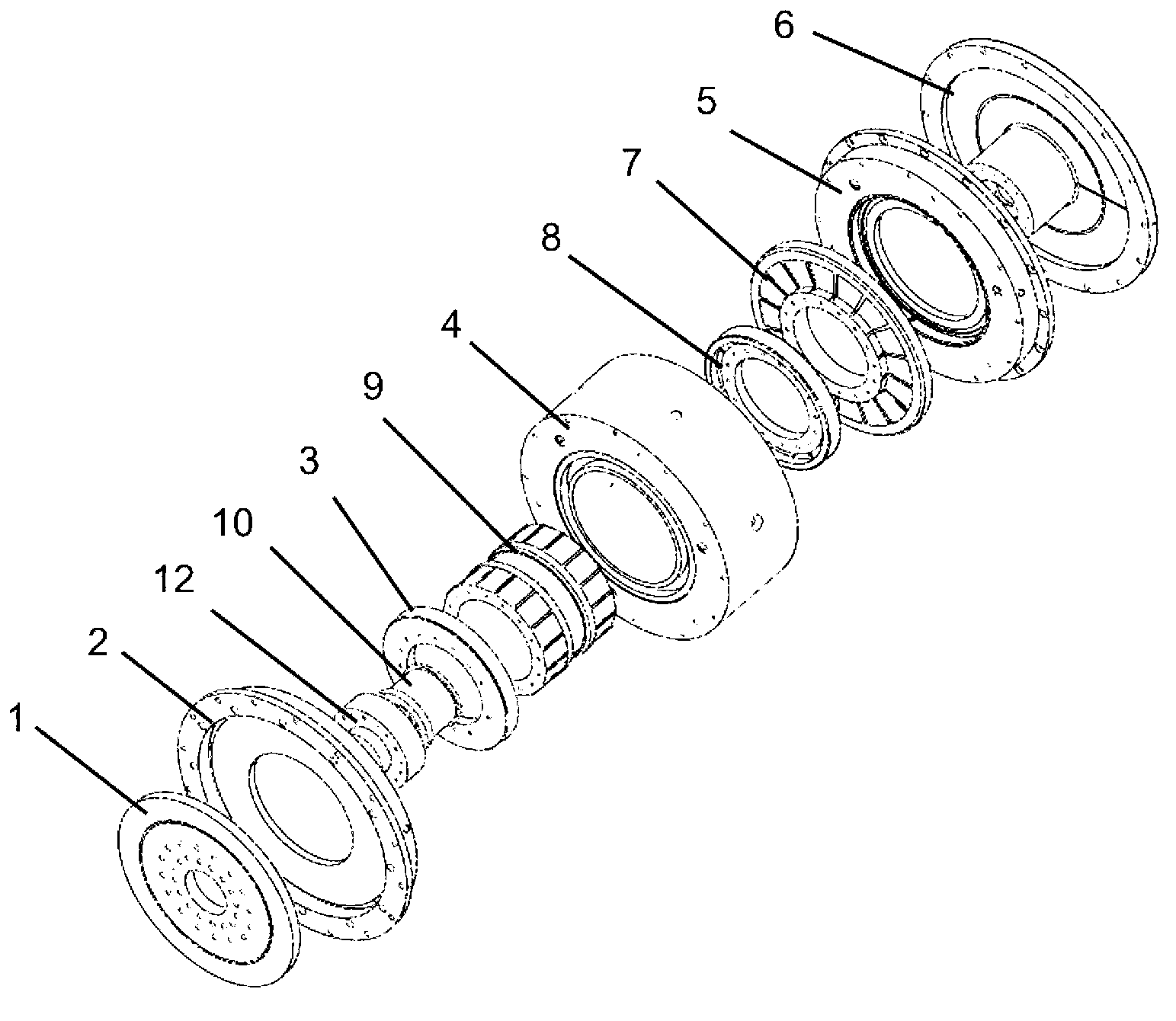

[0038] Such as figure 1 with 2 As shown, the stator system includes: a base 6 , a top end cover 2 , a stator ring 4 , a bottom end cover 5 and a motor stator 10 . The rotor system includes: a top rotor 1 , a top turntable 3 , a middle rotor 9 , a bottom turntable 8 , a bottom rotor 7 , a moto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap