Welding device with good welding effect

A welding device and heat dissipation device technology, which is applied in the field of material welding devices, can solve problems such as inability to process operations, resistance wires cannot be quickly cooled and shaped, and temperature and cooling are difficult to control, so as to save social resources, repeat constructive investment, and broaden the market The effect of popularizing space and reducing environmental damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

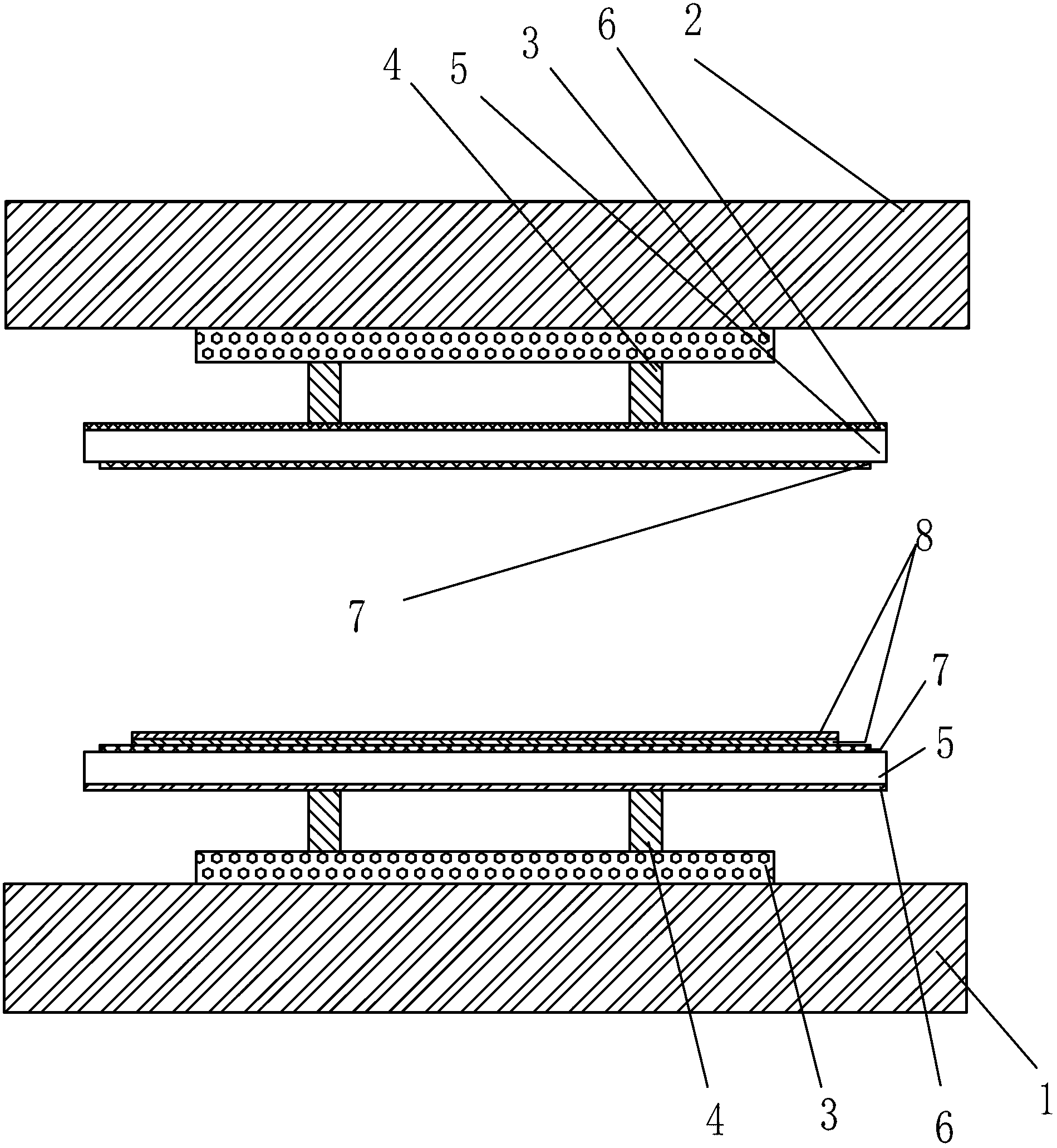

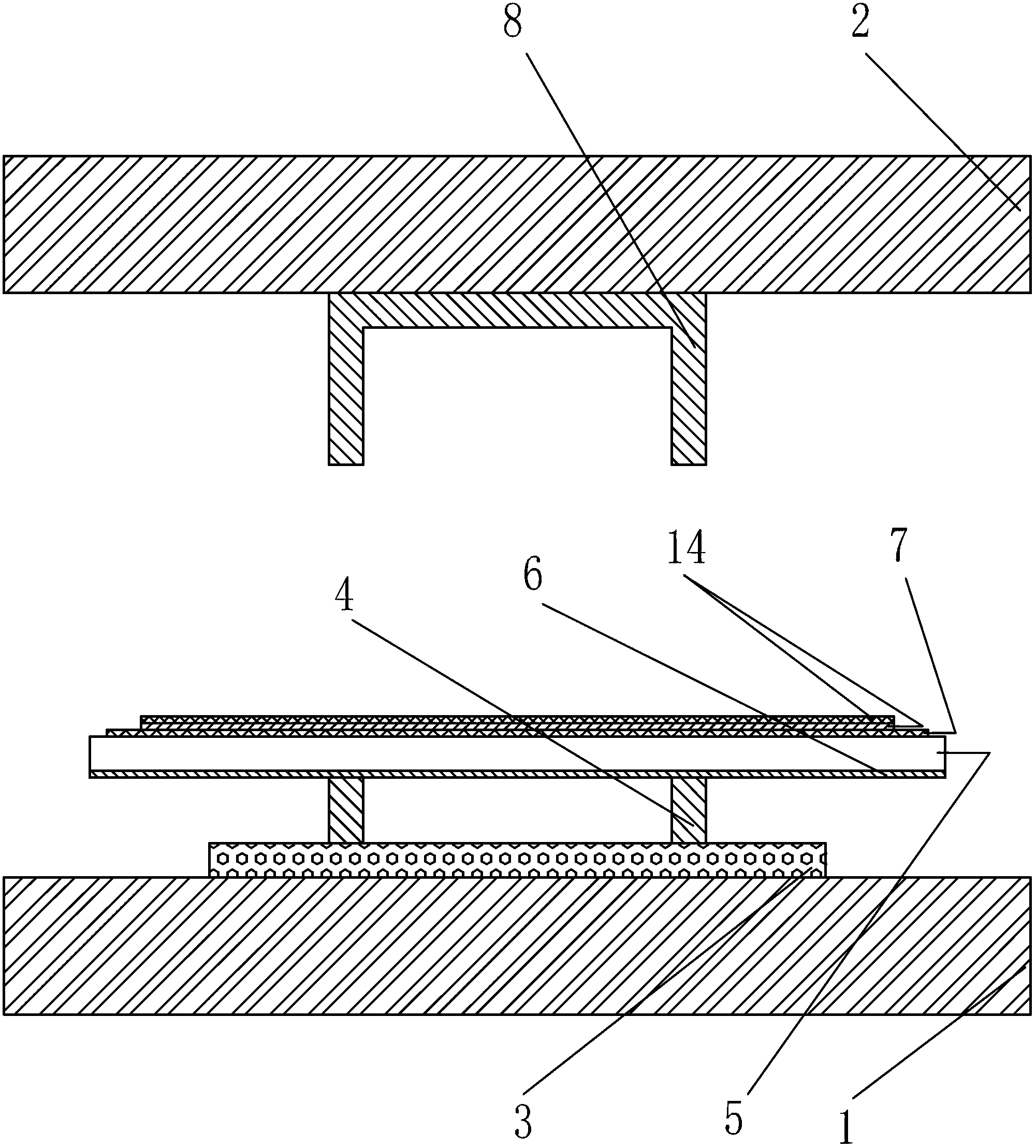

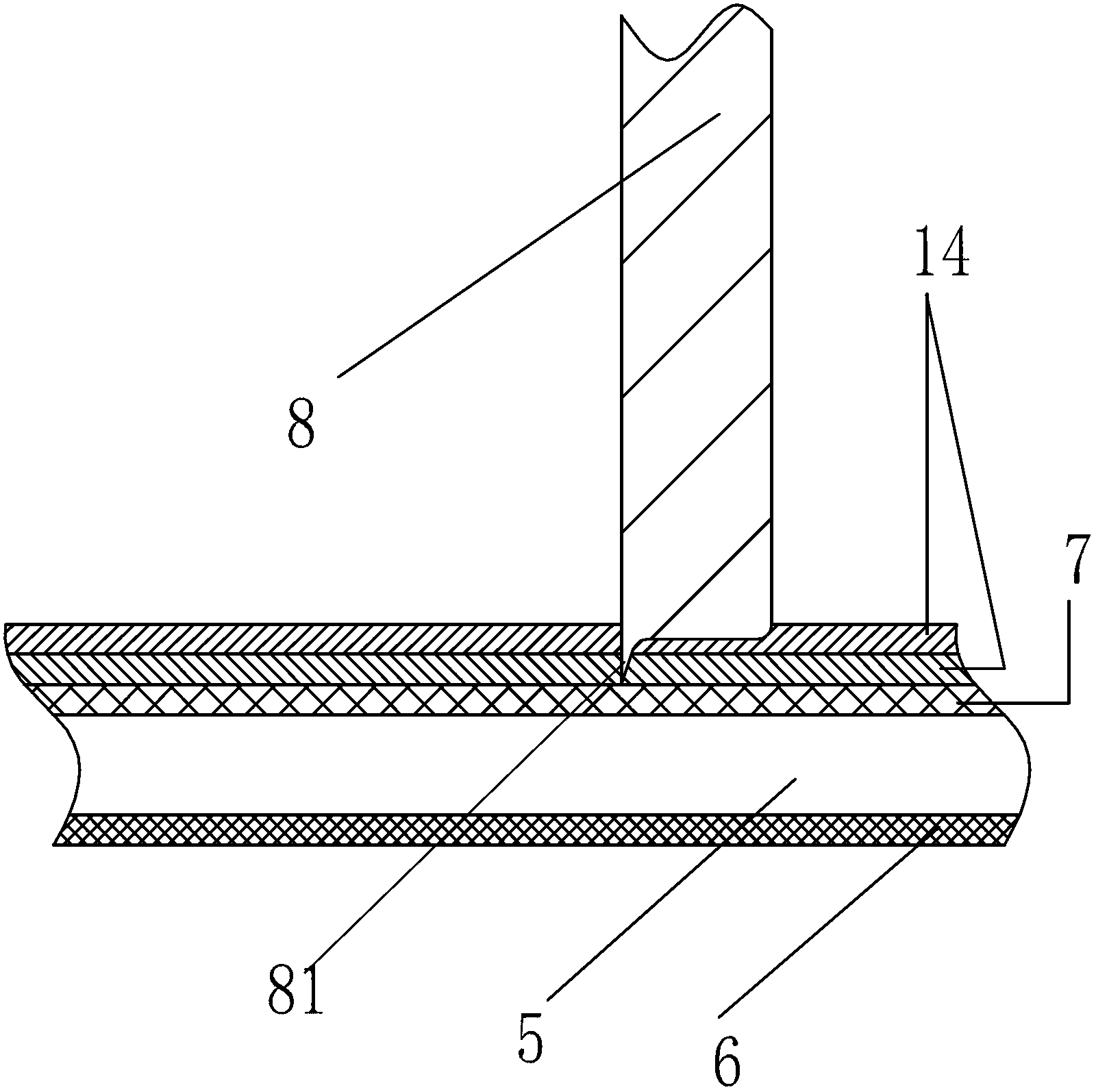

[0028] Such as figure 1 As shown, a welding device with a good welding effect includes a base plate 1 and a top plate 2 that is movable and presses against the base plate. A heat sink 3 is provided on the base plate 1. A conductive electrode 4 is provided on the heat sink 3. The conductive electrode 4 The other end of the electrode is connected to the electrode plate 5, and the bottom of the electrode plate 5 is provided with a dielectric layer 6 that plays a heating role when the high-frequency equipment is working and conducts heat to the electrode plate. The output end of the high-frequency equipment is correspondingly connected to the On the electrode plate 5 and the bottom plate 1.

[0029] When it is necessary to process welding relatively thin materials, it can be realized by single-sided addition, that is, a forming pressure mold 8 can be provided at the bottom of the top plate 2, and the shape of the conductive electrode 4 in contact with the forming pressure mold 8 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com