A logistics turnover box

A turnover box and logistics technology, applied in rigid containers, parts of bottles/cans, containers, etc., can solve the problems that adjacent boxes cannot be in close contact, are prone to mutual movement, and affect the effective use of space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

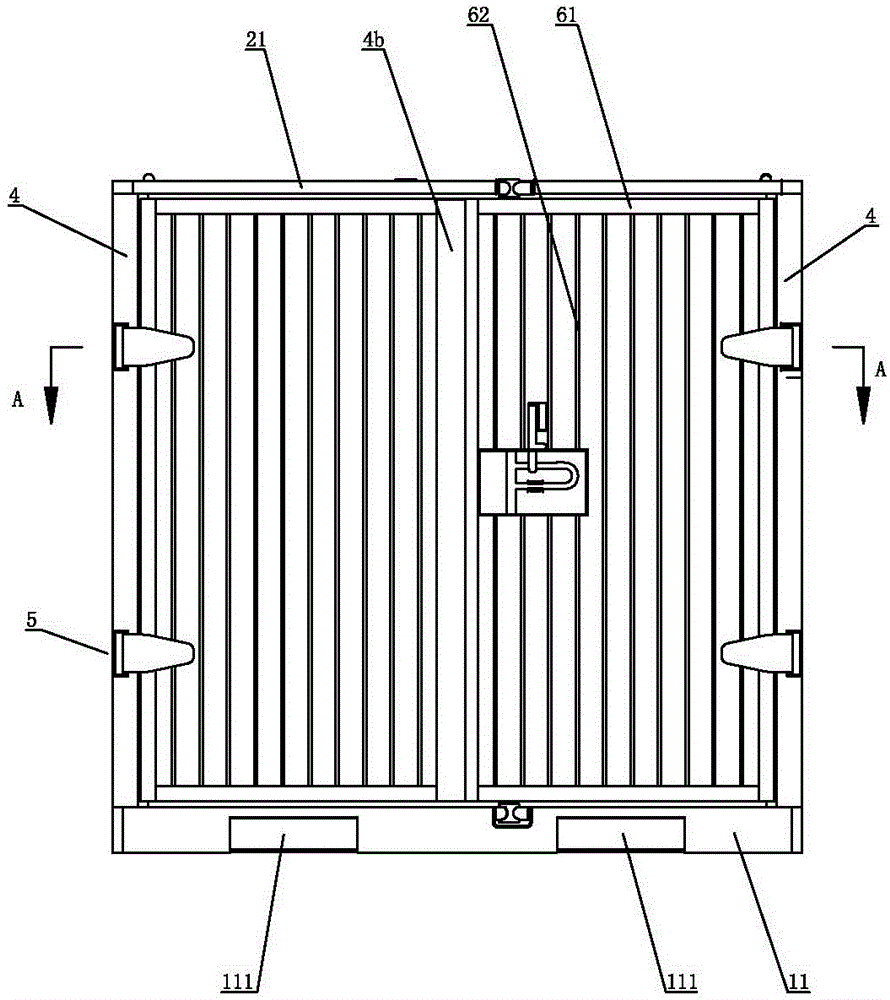

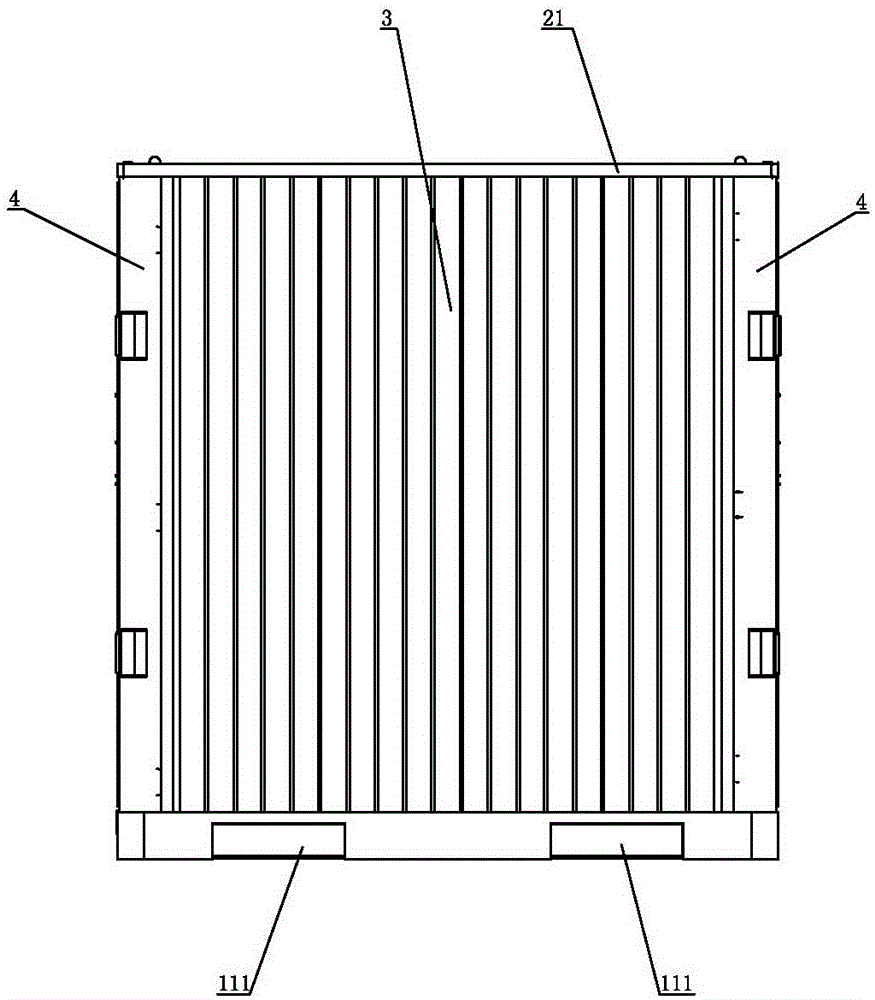

[0038] Such as Figure 1 to Figure 4 As shown, the logistics turnover box includes a box body, and the box body includes a bottom plate 1, a top plate 2, a side plate 3, a column 4 and a door lock device.

[0039] Such as Figure 4 As shown, the base plate 1 includes a base plate frame 11 and a base plate corrugated plate 12, the periphery of the base plate corrugated plate 12 is welded on the inner wall of the base plate frame 11, and a lower beam (not shown) is welded in the base plate frame 11, and the lower beam is used for supporting The base plate corrugated plate 12 is used to improve the bearing capacity of the base plate corrugated plate 12 . Such as figure 1 As shown, the side wall of the base frame 1 is provided with an insertion hole 111 for a forklift to facilitate the handling of the box.

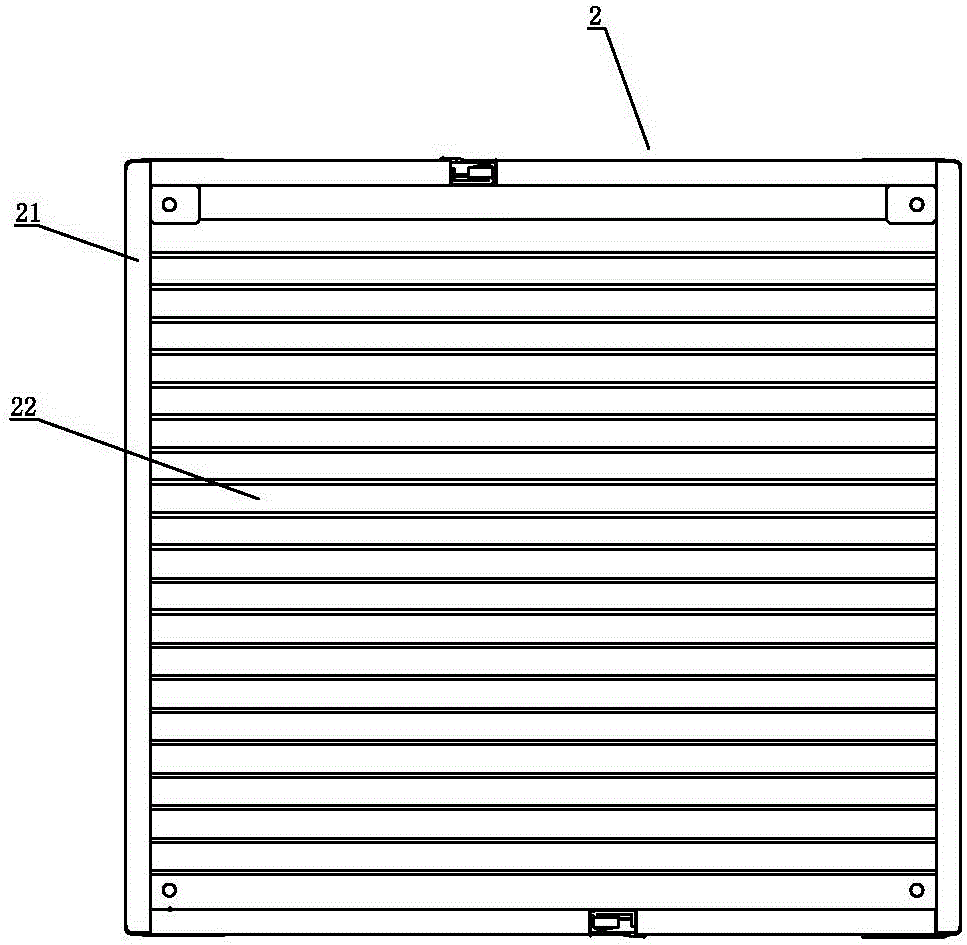

[0040] Such as figure 1 , 2 , 3, and 7, the roof 2 includes a roof frame 21 and a roof corrugated plate 22, and the surroundings of the roof corrugated plate 22 are welde...

no. 2 example

[0062] Such as Figure 12 to Figure 16 As shown, the logistics turnover box includes a box body, and the box body includes a bottom plate 1, a top plate 2, a side plate 3, a column 4 and a door lock device.

[0063] Such as Figure 16 As shown, the base plate 1 includes a base plate frame 11 and a base plate corrugated plate 12, the periphery of the base plate corrugated plate 12 is welded on the inner wall of the base plate frame 11, and a lower beam (not shown) is welded in the base plate frame 11, and the lower beam is used for supporting The base plate corrugated plate 12 is used to improve the bearing capacity of the base plate corrugated plate 12 . Such as Figure 12 As shown, the side wall of the base frame 1 is provided with an insertion hole 111 for a forklift to facilitate the handling of the box.

[0064] Such as Figure 12 , 13 As shown, the roof 2 includes a roof frame 21 and a roof corrugated plate (not shown), and the four sides of the roof corrugated plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com