Chisel holder

A tool holder and tool technology, applied in cutting machinery, stone processing equipment, construction, etc., can solve the problems of tool holder wear, cost, high tool cost, machine downtime, etc., and achieve the effect that is beneficial to cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

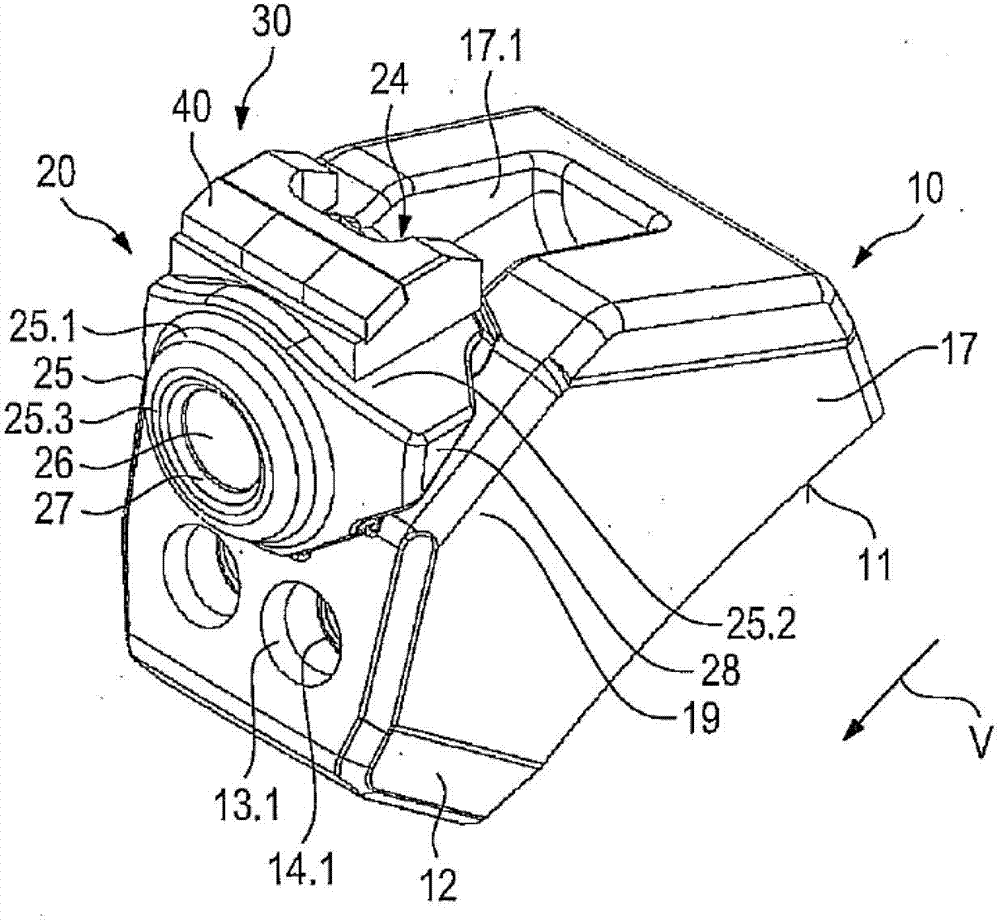

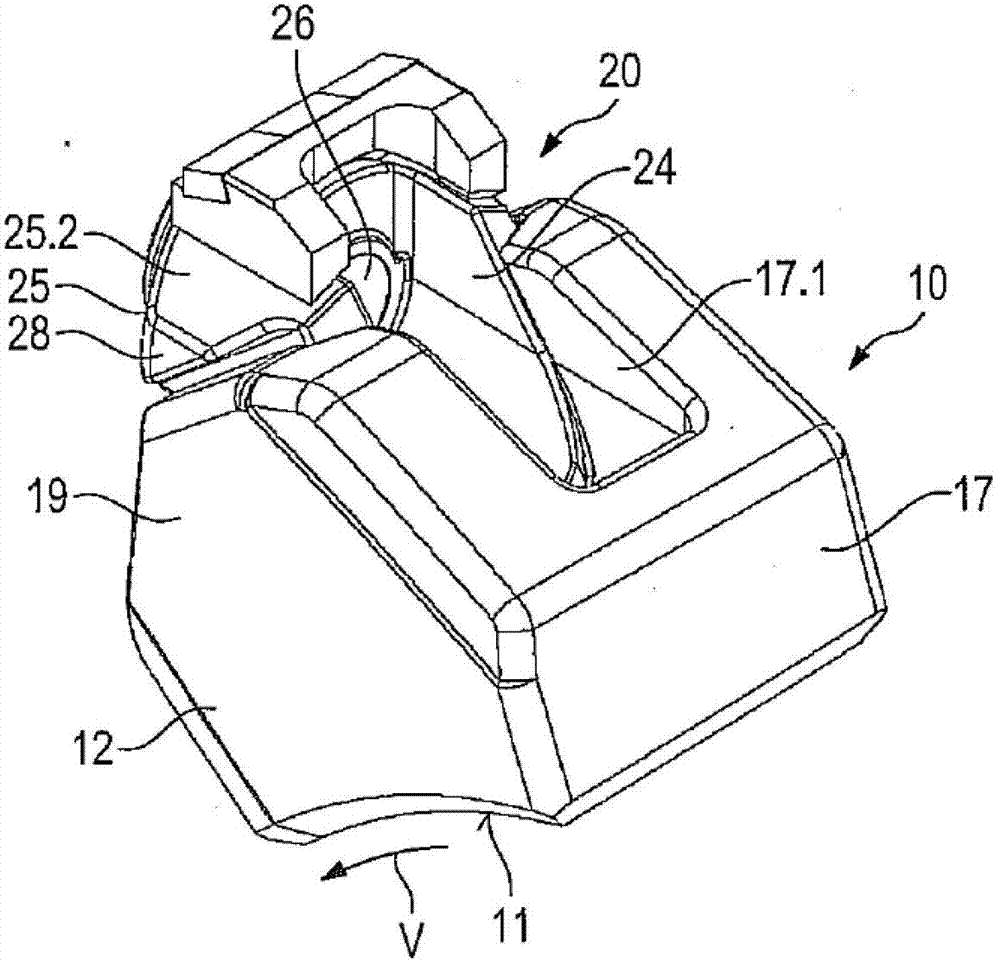

[0037] figure 1Base part 10 is shown with an underside 11 having a concavely arched seating surface. By means of this mounting surface, the base part can be placed on the cylindrical outer surface of the milling roller and fixedly welded thereto. The tool holder 20 is connected to the base part 10 .

[0038] like Figure 5 As shown, the base part 10 has a plug receptacle 15 which accommodates the plug-in projection 21 of the tool holder 20 . Refer below Figure 6 to Figure 8 The structure of the tool holder 20 is explained in detail.

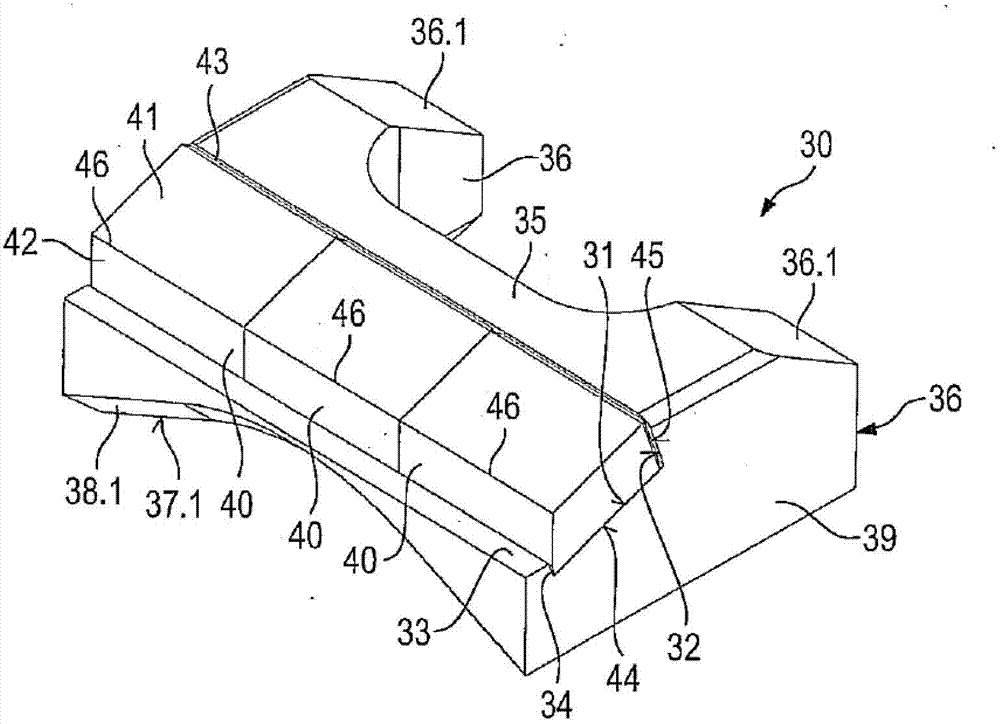

[0039] like Image 6 As shown, the tool holder 20 has an insertion projection 21 to which a support projection 25 is attached at an angle. In this case, an obtuse angle is ideally enclosed between the insertion projection 21 and the support projection 25 . The insertion projection 21 forms a front side 21 . 1 in the region of its insertion projection front side 22 facing the tool feed direction V. The two grooves are formed in the front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com