Construction method of hoisting arch-girder combined bridge

A construction method and technology of arch beams, which are applied in the directions of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of large impact on urban environment and residents' lives, occupation of large construction sites, inconvenient urban traffic, etc., and achieve easy control of construction Quality, reduce construction cost and construction period, and reduce labor consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

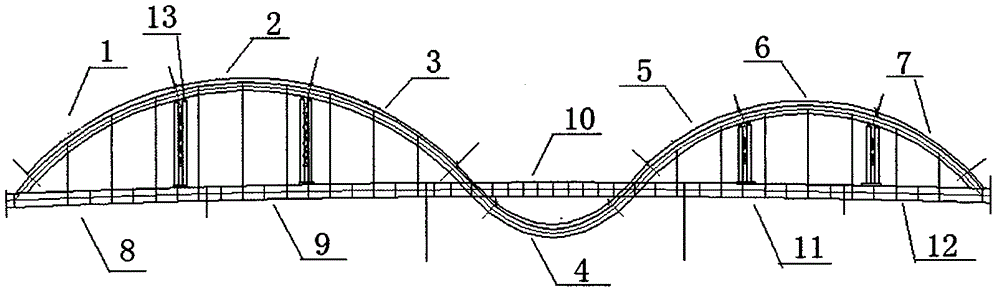

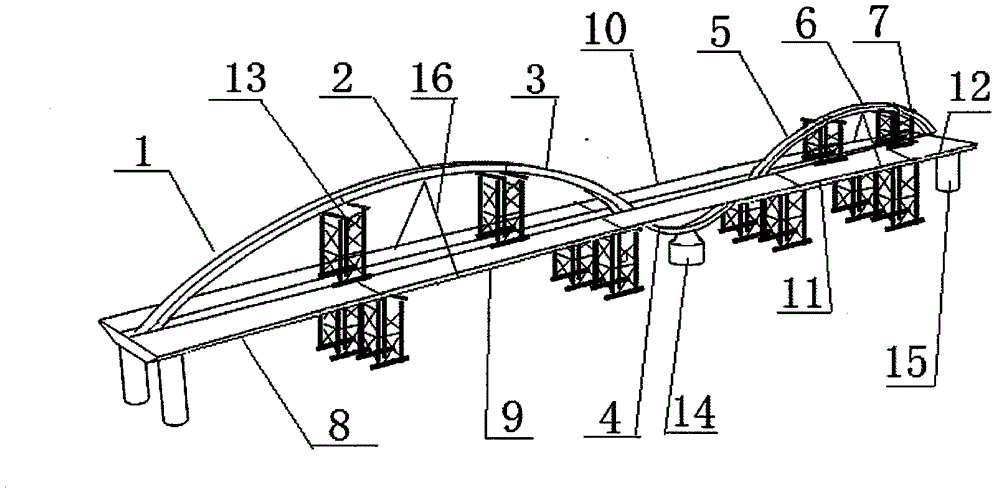

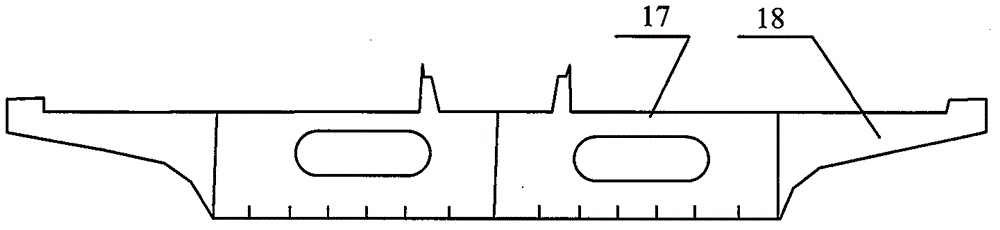

[0046] Example: The arch-beam combined bridge adopts a suspended arch structure, the material is Q345D, and the span combination is 40 meters + 32 meters; the height of the 40-meter-span A arch rib is 7.8 meters, and the 32-meter-span C arch rib height is 6 meters; steel box girder The height is 1 meter, and the width of the whole bridge is 6.5 meters; the two-span steel box girders are arranged continuously, the main span is 6.5 meters wide, and the thickness of the roof is 12mm and 20mm; The standard spacing is 315mm, and the whole bridge is arranged continuously; the standard thickness of the bottom plate is 14mm, and the bottom plate at the local support position is thickened to 20mm. There are 3 webs and 16 suspension cables for the whole bridge; the upper and lower arch ribs of large and small spans It is a constant-section box girder section with a slab thickness of 20mm. The exterior is decorated with 6mm thin slabs to form a trapezoidal section to enhance the decorativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com