Hydraulic system return oil filter device with flow measuring function

A hydraulic system and flow measurement technology, which is applied in fluid pressure actuation devices, fluid pressure actuation system components, mechanical equipment, etc., can solve problems such as complex and cumbersome systems, harsh installation conditions, and long straight pipe sections to ensure safety The effect of operation, extended service life and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

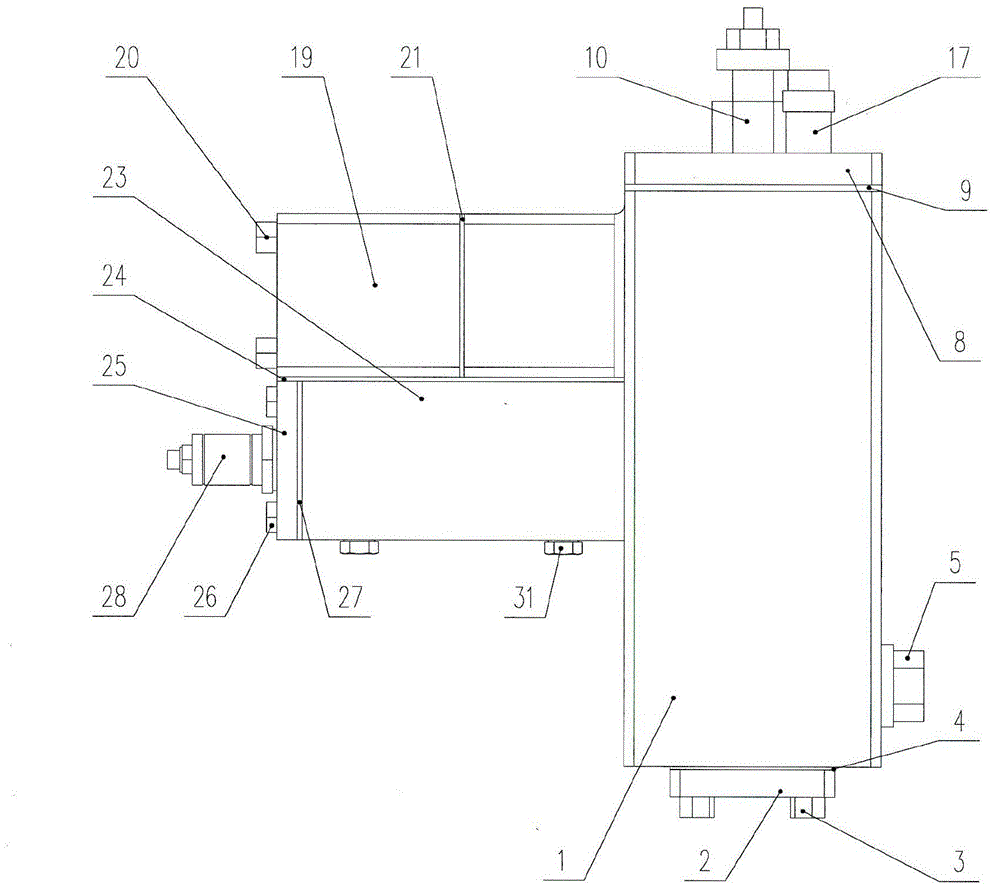

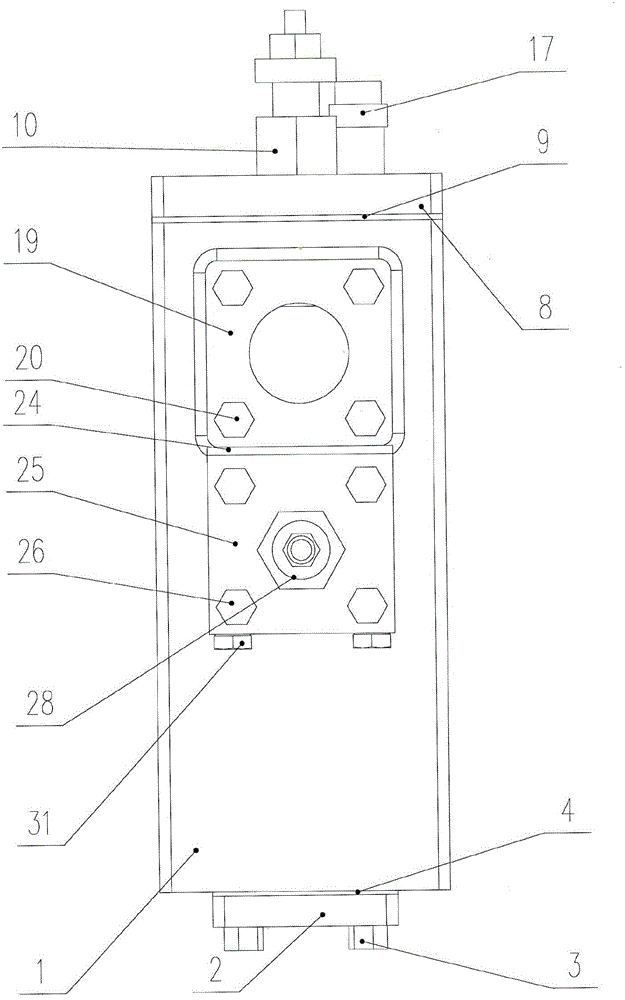

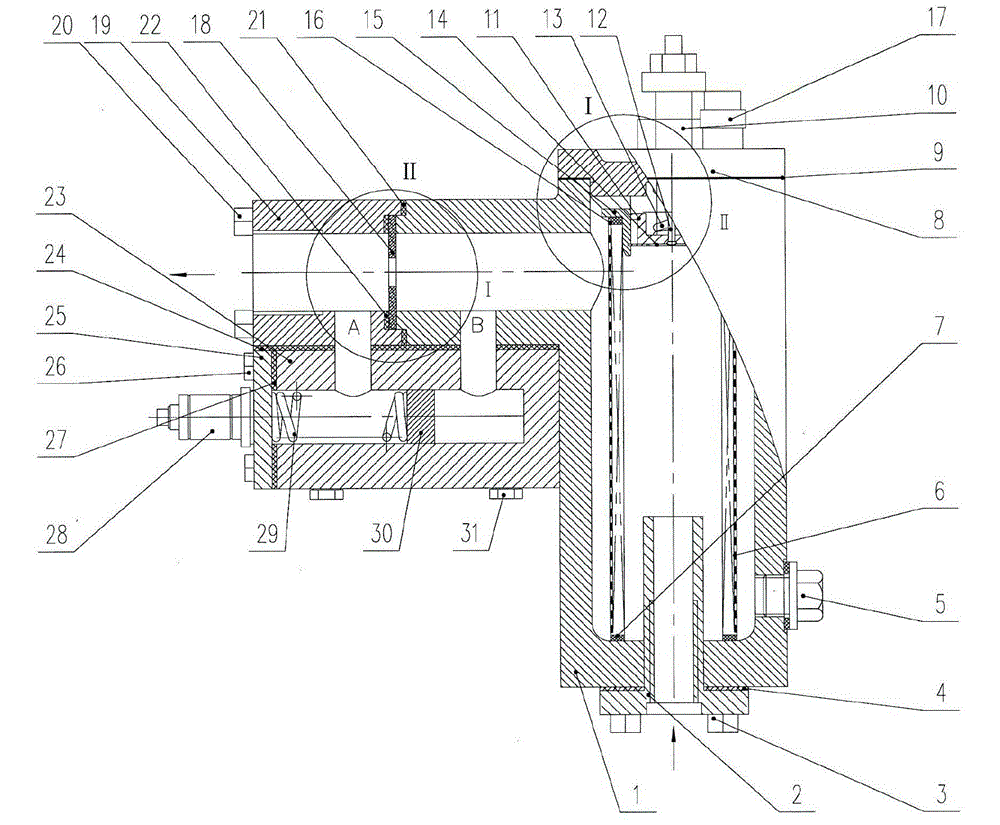

[0016] exist figure 1 , figure 2 and image 3 In the schematic diagram of the oil return filter device of the hydraulic system with flow measurement function shown, the main housing 1 is composed of a vertical cylinder and a horizontal cylinder vertically connected to its upper part. The lower end of the vertical part of the main housing is provided with an oil inlet, and an inner pipe 2 extending toward the main housing is arranged on the oil inlet. The inner pipe is connected with the main housing through screws 3, and the main housing and the inner pipe A sealing gasket 4 is arranged between them, and the inner thread of the inner pipe can be threadedly connected with the oil return pipeline. The lower wall of the vertical part of the main housing is provided with an oil drain, on which a screw plug 5 is provided. A cylindrical filter screen 6 whose height exceeds the inner chamber of the horizontal part of the main housing is arranged in the vertical part of the main h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com