Heat exchanger

A technology of heat exchanger and heat exchange medium, which is applied in heat storage heaters, fluid heaters, lighting and heating equipment, etc. It can solve the problems of affecting medium channels, uneven heat exchange, easy scaling, etc., and achieve uniform temperature , Solve the effect of uneven heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

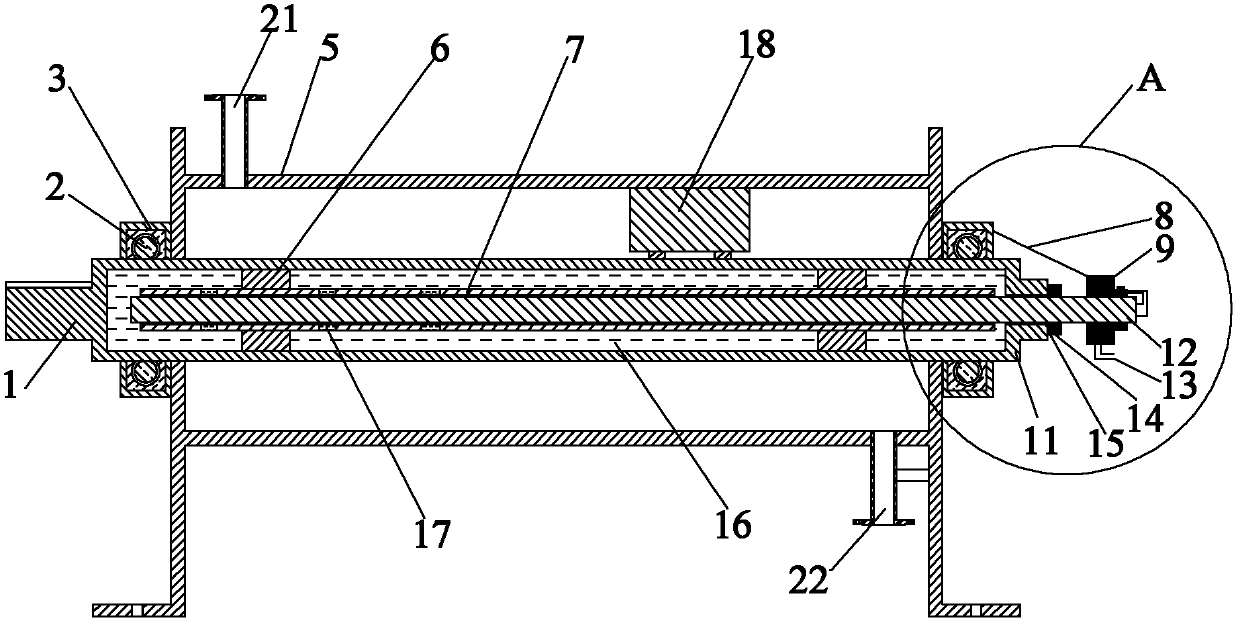

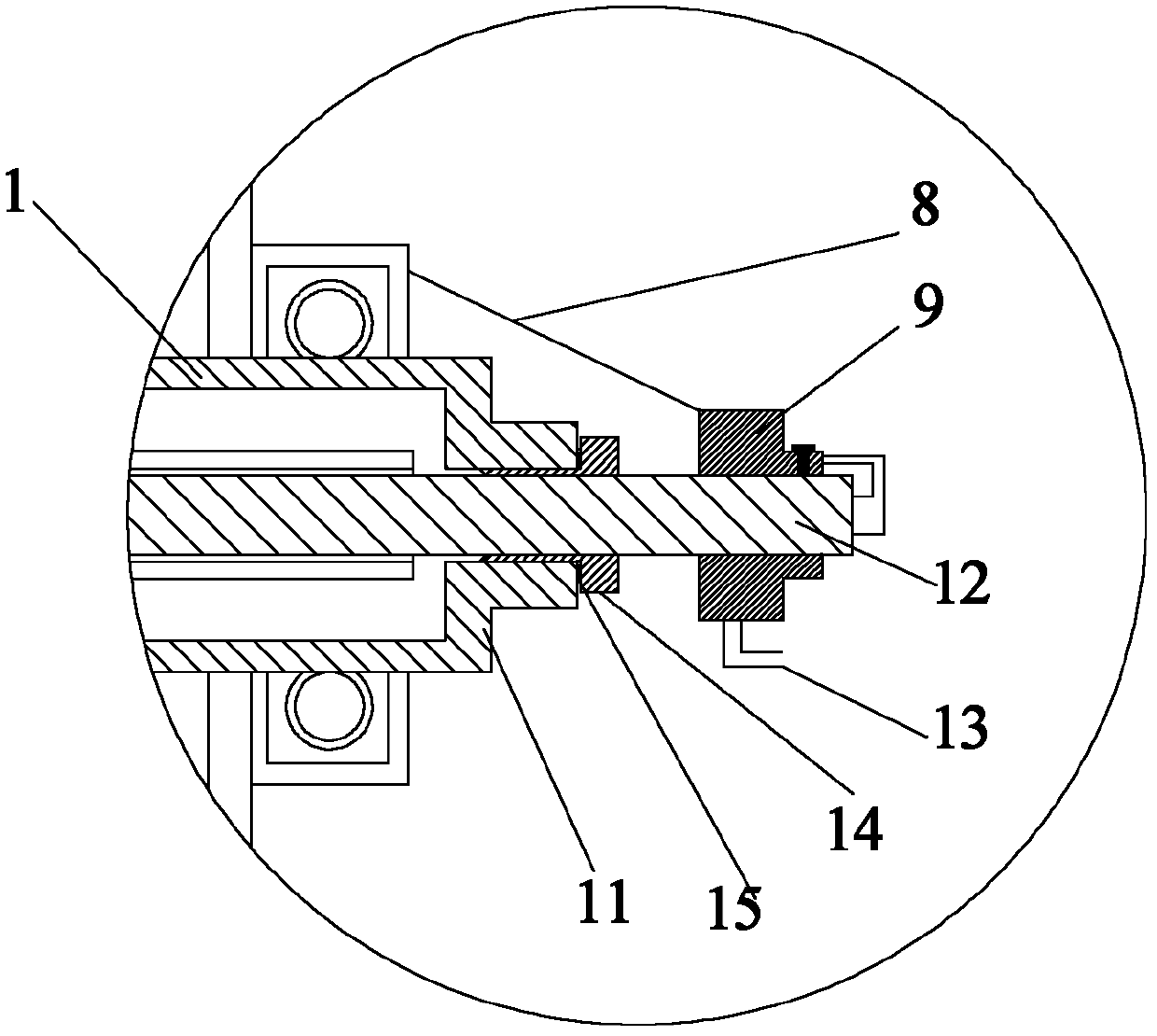

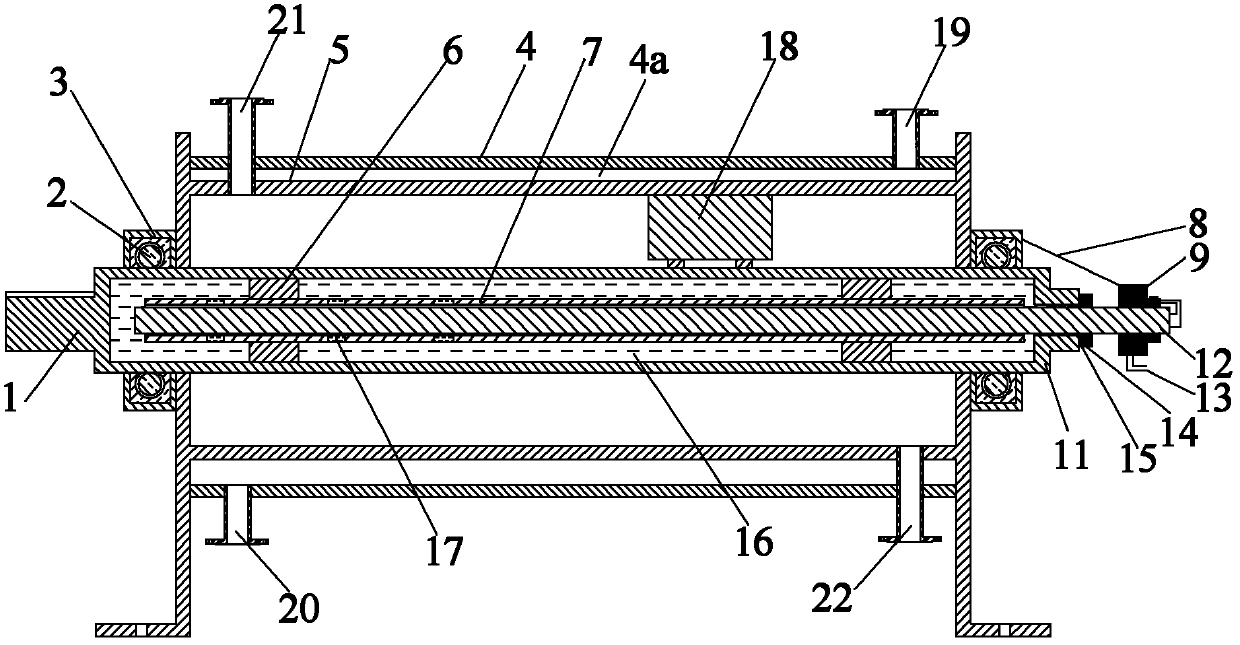

[0025] In the heat exchanger of Embodiment 1, a heat exchange medium 16 and a heating device 12 that rotates synchronously with the main shaft 1 are arranged inside the main shaft 1. The heating device 12 continuously heats the heat exchange medium 16 for constant temperature control, so that the temperature of the heat exchange medium 16 is uniform, and then Solved the problem of uneven heat transfer.

[0026] Preferably, the heat exchange medium 16 is heat transfer oil. This prevents scaling and requires no additional maintenance.

[0027] The main shaft 1 is generally driven by a motor and a reducer. In order to enable the main shaft 1 and the heating device 12 to rotate synchronously, preferably, the inner wall of the main shaft 1 is connected with a sleeve bracket 6, and the outer side of the heating device 12 is sleeved with a connecting sleeve 7. The pipe support 6 is connected with the connecting sleeve 7 . As a feasible implementation known to those skilled in the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com