Ultrasonic thickness measurement method for multiple medium layers

An ultrasonic and multi-medium technology, applied in the direction of using ultrasonic/sonic/infrasonic waves, measuring devices, instruments, etc., can solve the problems of inability to achieve multi-layered medium measurement, difficult to reflect echoes, etc., to save detection costs, shorten detection time, Apply a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

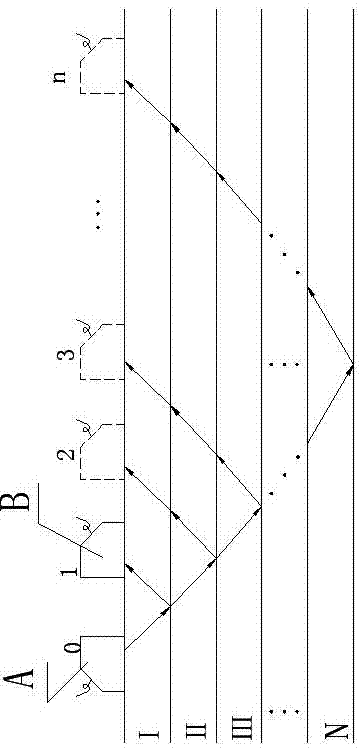

[0019] The present invention is a multi-media layer ultrasonic thickness measurement method, as an embodiment of the present invention, such as figure 1 As shown, a multi-media layer ultrasonic thickness measurement method uses ultrasonic transmitting angled probe A, ultrasonic receiving angled probe B to transmit and receive ultrasonic waves and the refraction and reflection relationship of ultrasonic waves to realize the measurement of each medium layer I, II, III... Measurement of the thickness of N itself. See specific steps figure 1 :

[0020] Step 1: Paste the ultrasonic emitting oblique probe A at position 0 on the surface of the uppermost layer of the multi-layer medium with grease to emit ultrasonic waves into the medium. The position will not change in the following steps, but the ultrasonic emitting oblique The incident angle of probe A changes according to the thickness of each medium to be measured, and the incident angle range is selected as ;

[0021] Step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com