An ultrasonic probe fixture

A technology of ultrasonic probes and fixtures, which is used in the application of ultrasonic/sonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, measurement devices, etc. Replacement and other issues to ensure the effect of water coupling and the stability of scanning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

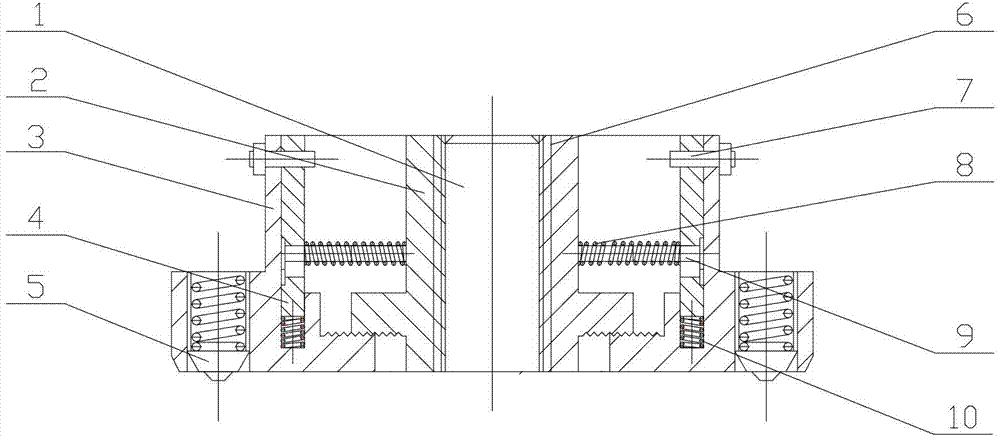

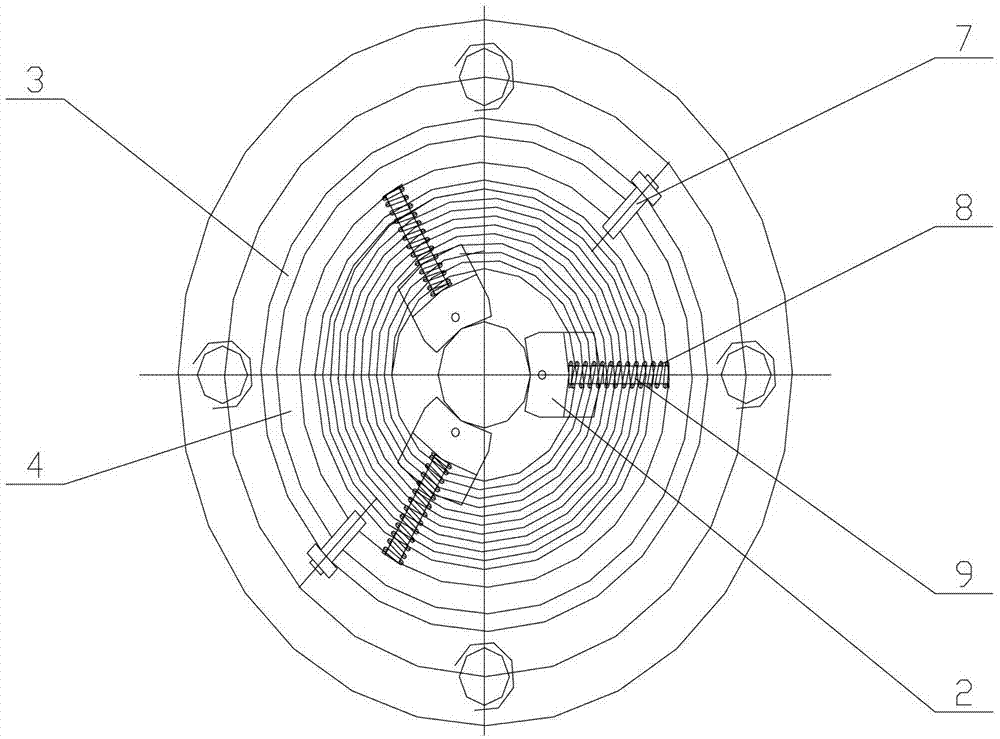

[0024] A kind of ultrasonic probe fixture of the present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

[0025] like figure 1 As shown, an ultrasonic probe clamp includes a support block 2 , a clamp inner ring 4 , a base 3 , a spring pin 7 , a support spring 8 , a telescopic rod 9 and a compression spring 10 .

[0026] Wherein, the base 3 is a ring-shaped structure with annular bosses on both sides of the inner and outer sides, and a through hole is opened on the outer boss as a ball roller mounting hole, and the inner boss is stepped, and the inner part of the inner boss is higher than the outer Part 2-3cm, such as 2cm, 2.5cm or 3cm; an annular groove is arranged on the inner part of the inner boss, and a thread is arranged on the top of the outer part of the inner boss. The upper part of the base 3 has a through hole as a spring pin mounting hole for mounting the spring pin 7; generally, there are multiple spring pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com