Method and device for determining driving voltages

A technique for determining a driving voltage and a method for determining it, applied in the field of a method and device for determining a driving voltage, capable of solving problems such as afterimages in liquid crystal displays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

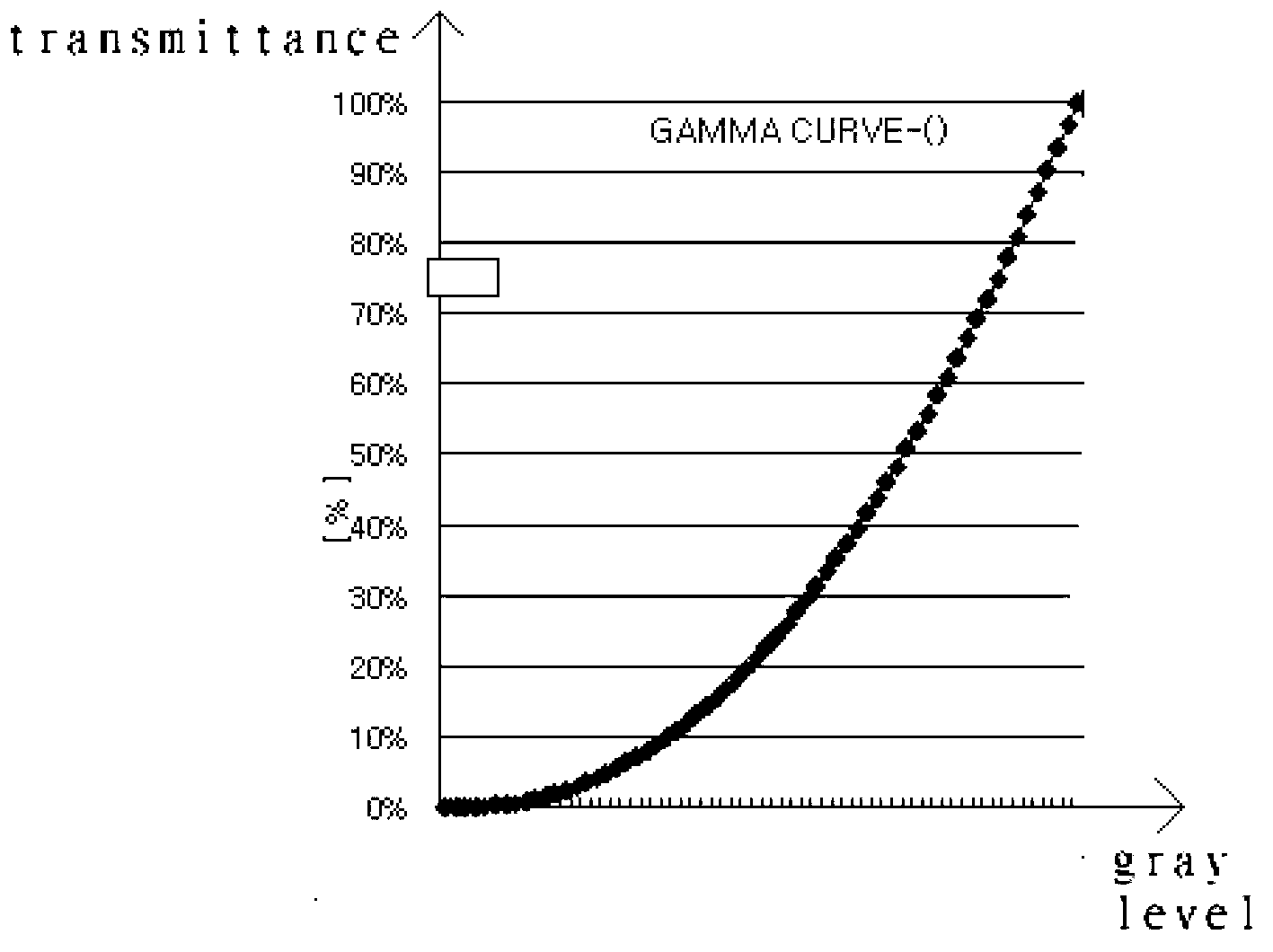

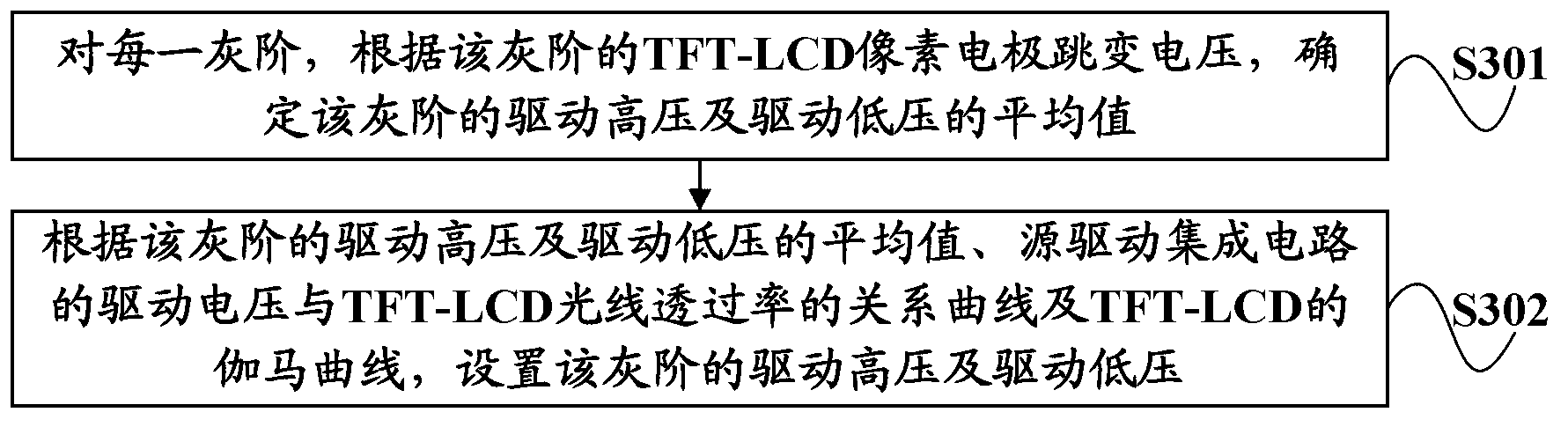

[0025] Embodiments of the present invention provide a method and device for determining a driving voltage. When setting the driving high voltage and driving low voltage of a TFT-LCD, for each gray scale, first determine a The average value of the driving high voltage and driving low voltage of the gray scale, and then according to the determined average value of the driving high voltage and driving low voltage of the gray scale, the relationship curve between the driving voltage of the source driver integrated circuit and the light transmittance of the TFT-LCD, and the TFT -LCD gamma curve, to set the TFT-LCD drive high voltage and drive low voltage, because the average value of the drive high voltage and drive low voltage is determined according to the TFT-LCD pixel electrode jump voltage, not because the pixel electrode jump voltage is different from The difference between the average value of the gray-scale driving high voltage and driving low voltage and the reference volta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com