Support clip for high current switch flipping

A technology of high-current switch and support clip, which is applied in the direction of open busbar installation, etc., can solve the problems of production workers such as skin allergies, rough cutting surface, and difficult processing, and achieve the effect of eliminating hidden dangers of skin allergies, improving cost performance, and beautiful layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

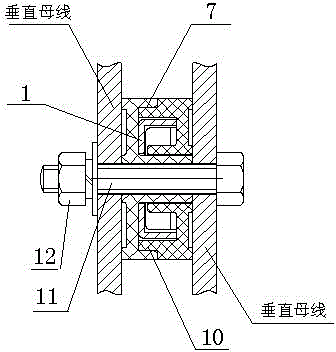

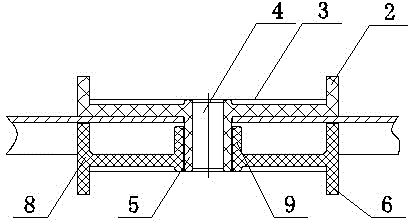

[0010] Referring to the accompanying drawings, its structure includes a metal mounting beam 1, A supporting clip 2, a limit groove 3, a bolt hole 4, a protruding cylinder 5, a reinforcing rib 6, an upper and lower engaging notch 7, a B supporting clip 8, and a cylindrical sleeve Cylinder 9, embracing side 10, mounting bolt 11, and tightening nut 12; A side surface of support clip 2 is provided with a limit groove with a width of more than 80mm for placing a copper busbar with a width of more than 80mm. There are bolt holes 4 for clamping on the side of the clamp, and the upper and lower ends of the limit groove 3 are provided with reinforcing ribs 6 to prevent deformation of the parts; the other side of the A support clamp 2 is provided with a cylindrical bolt hole. Sleeve 9, this cylindrical sleeve 9 should be able to match the outer diameter of the protruding cylinder 5 of the B support clip.

[0011] On the periphery of the cylindrical surface of the A support clip 2, there...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com