Packaging container and packaging body

A technology of packaging containers and loading plates, which is applied in the direction of containers, packaging, rigid containers, etc., can solve the problems of poor handling efficiency and achieve stable and fixed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, one embodiment of the packaging method and package body of the present invention will be described, but the present invention is not limited to the embodiment described below.

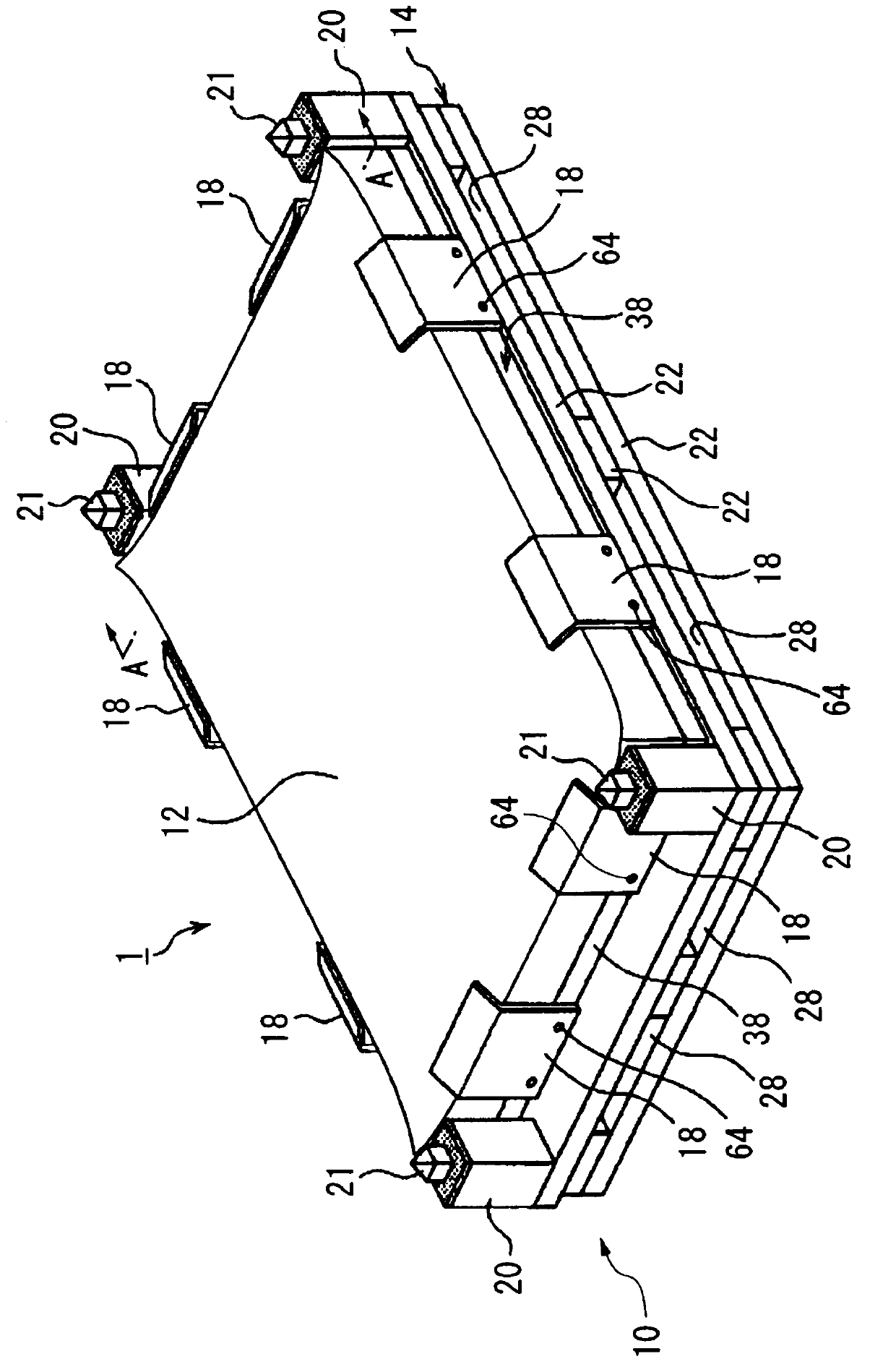

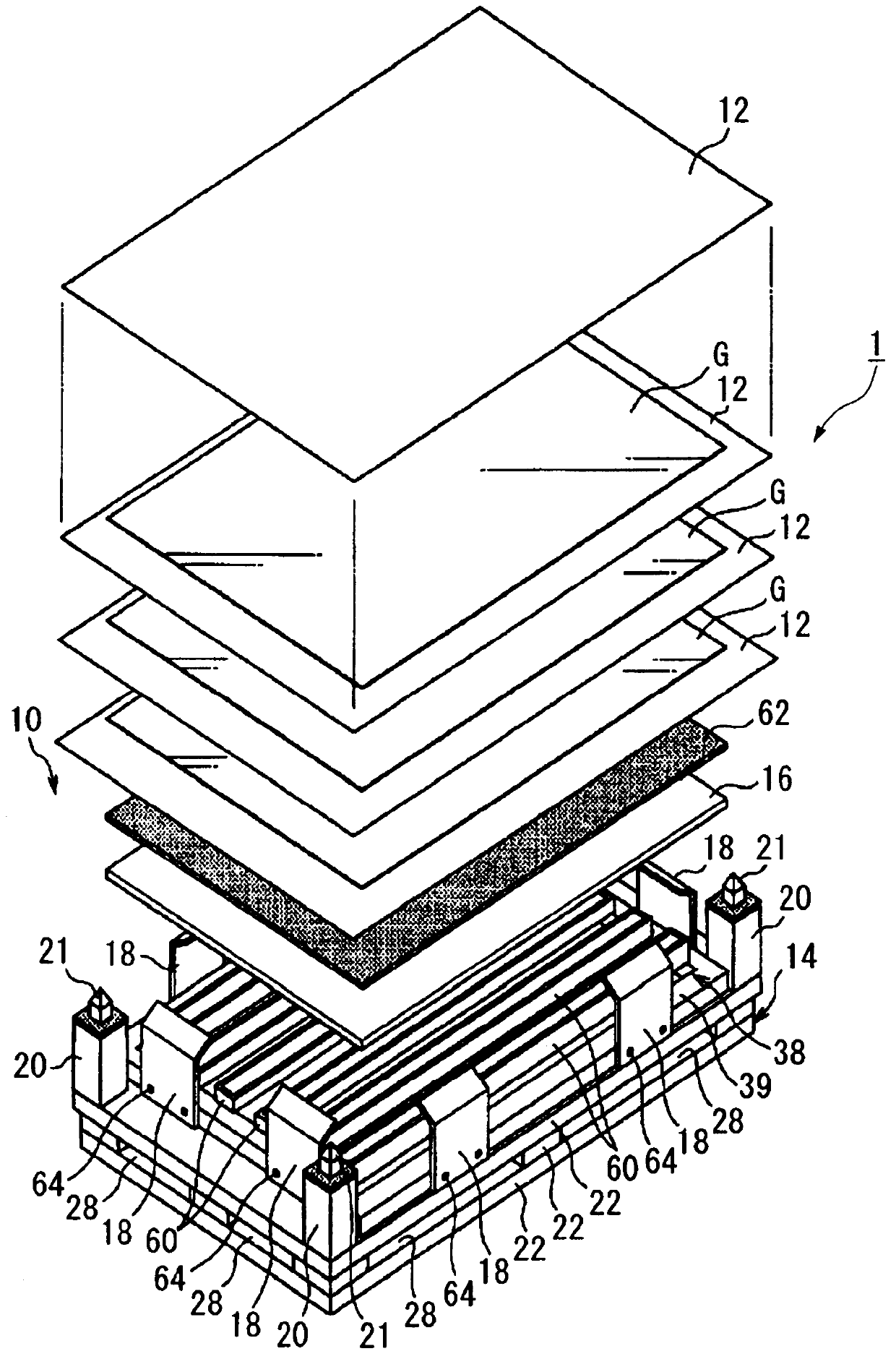

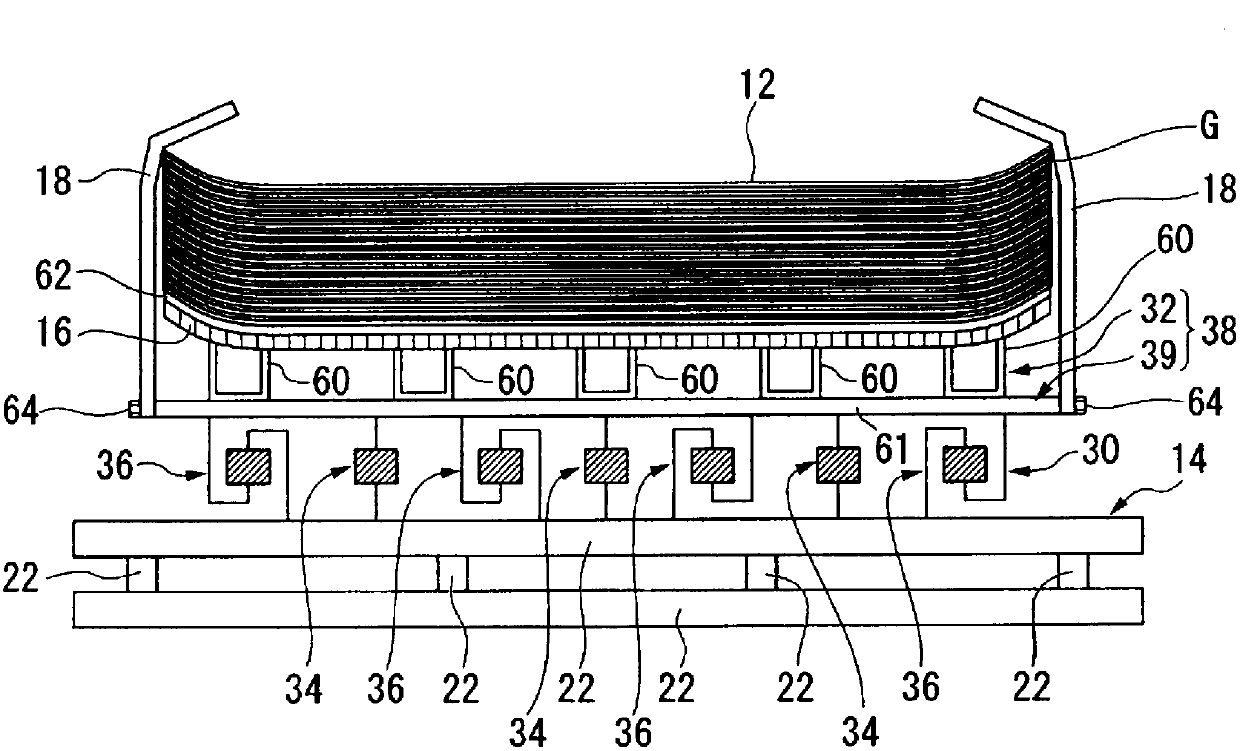

[0030] figure 1 It is a perspective view which shows the appearance of the glass plate package 1 of this embodiment, figure 2 It is an exploded perspective view for explaining the schematic structure of the package 1 which laminated|stacked and hold|maintained on the packaging container 10 several glass plates G horizontally.

[0031] A plurality of (for example, 80 to 150) rectangular glass plates G are stacked substantially horizontally and stored in the packaging container 10 . And the mounting paper 12 formed in rectangular shape with the area larger than glass plate G is sandwiched between glass plate G. The glass plate G shown in this embodiment is a thin large glass substrate used in FPDs, and is, for example, a large glass plate with a thickness of 0.5 mm to 2.8 mm and a ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap