Valve device for high voltage cable insulator manufacturing

A high-voltage cable, valve device technology, applied in the field of valve devices, to achieve the effects of stable electrical and mechanical properties, reduced time and/or economic costs, and precise opening and closing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

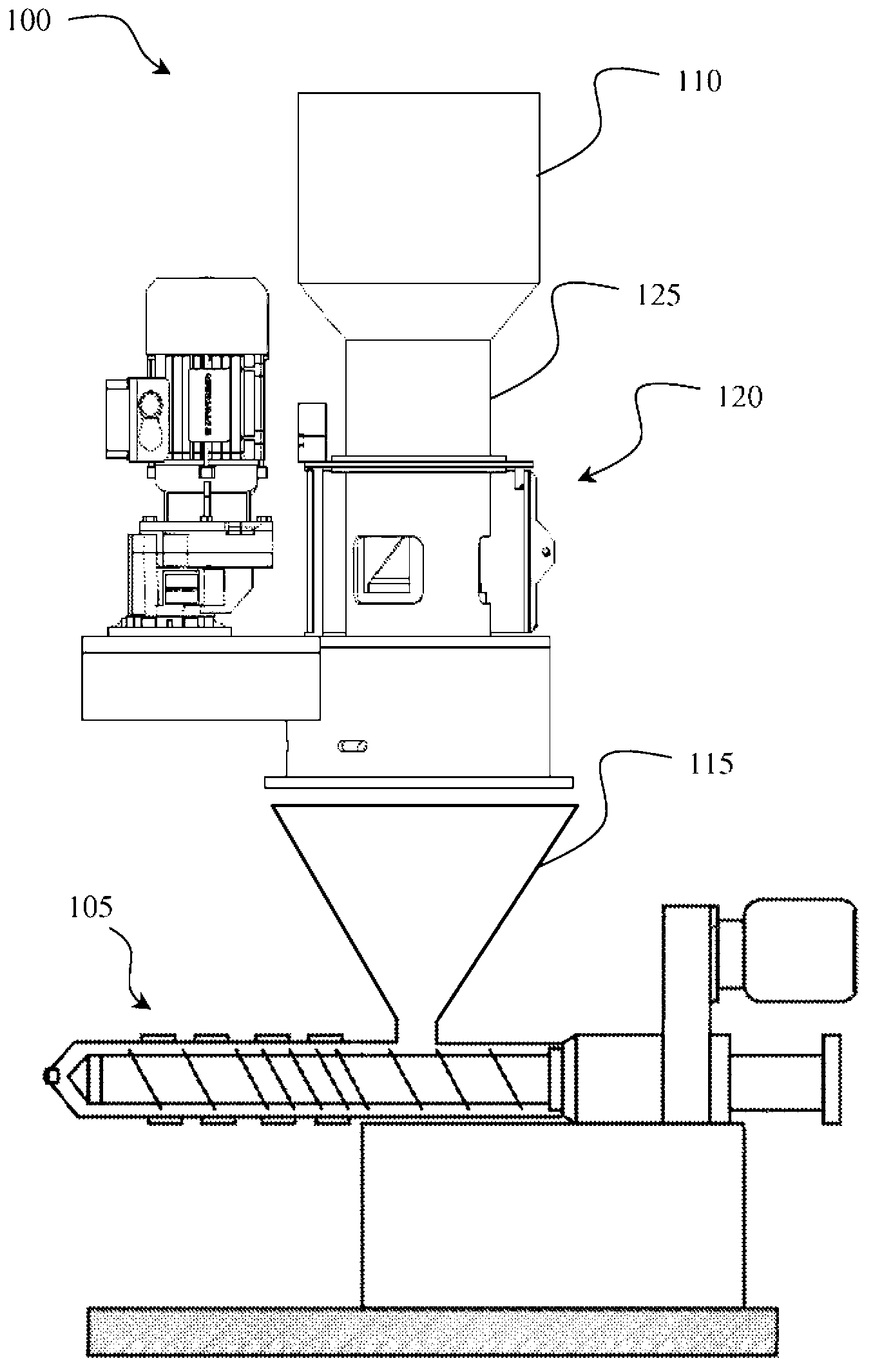

[0029] With reference to the accompanying drawings, especially figure 1 , which schematically shows an extrusion device according to an embodiment of the invention, which is specifically designed for forming cable insulation, especially for high voltage cables.

[0030] The extrusion device comprises an extruder feed device 100 for supplying the raw material to be extruded to an extruder 105; more particularly, in the envisaged scenario, the feed device 100 is adapted to feed pellets of thermoplastic material to An extruder 105 which, by extrusion, allows the central conductor (cable core) of a high-voltage cable (not shown in the drawings) to be covered with an insulating coating as a cable insulation of the high-voltage cable.

[0031] The extruder 105 is a well known machine and is widely used in the art, therefore it is only schematically depicted in the figures. Basically, once the thermoplastic material pellets are fed to the extruder 105, the pellets are in frictional ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap