Automatic feeding device of punching machine

A technology of automatic feeding and punching machine tools, applied in the directions of feeding devices, positioning devices, storage devices, etc., can solve the problems of easy disability, high cost, stagnant work efficiency, etc., to improve work efficiency, work safety and reliability. , the effect of ingenious design structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

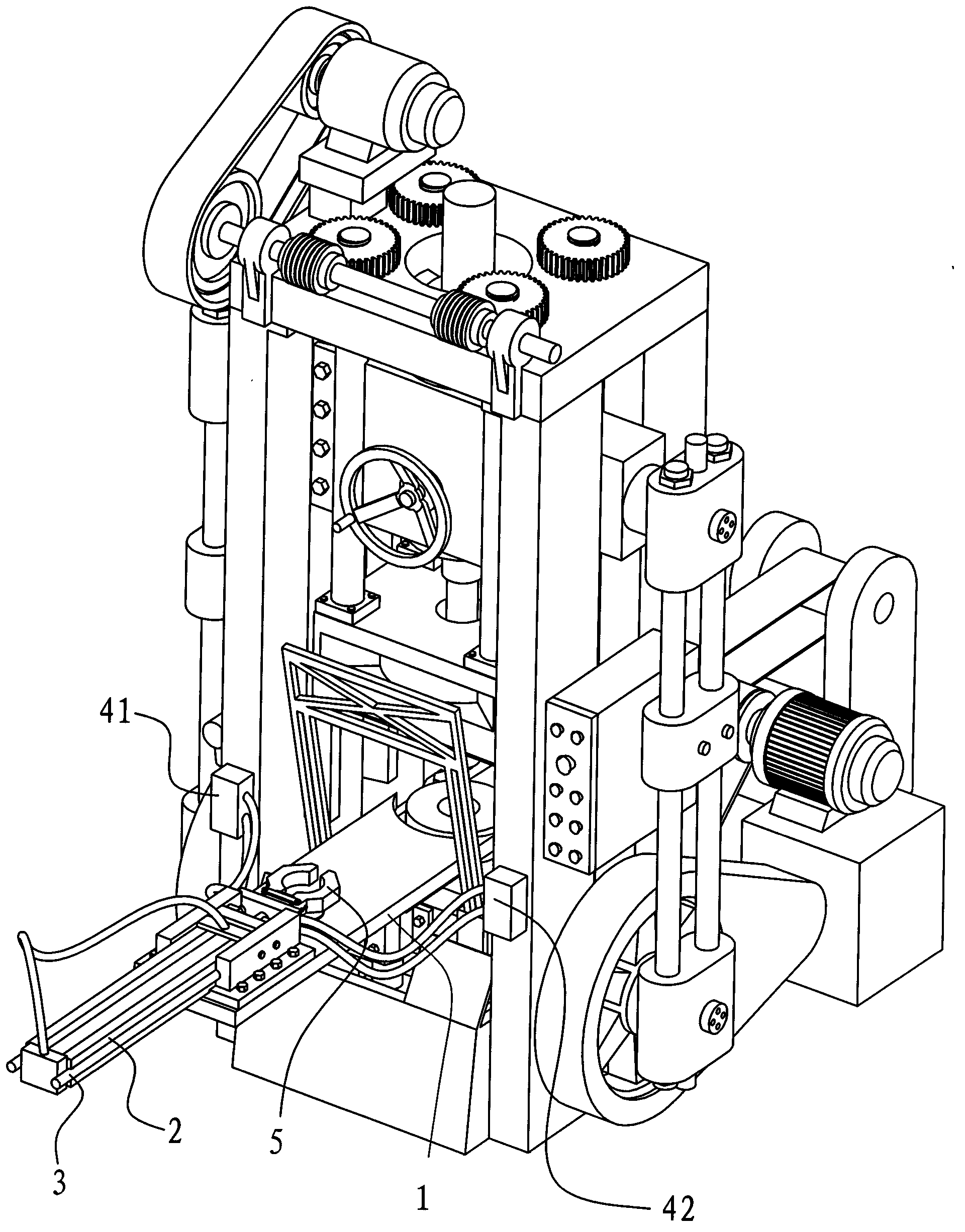

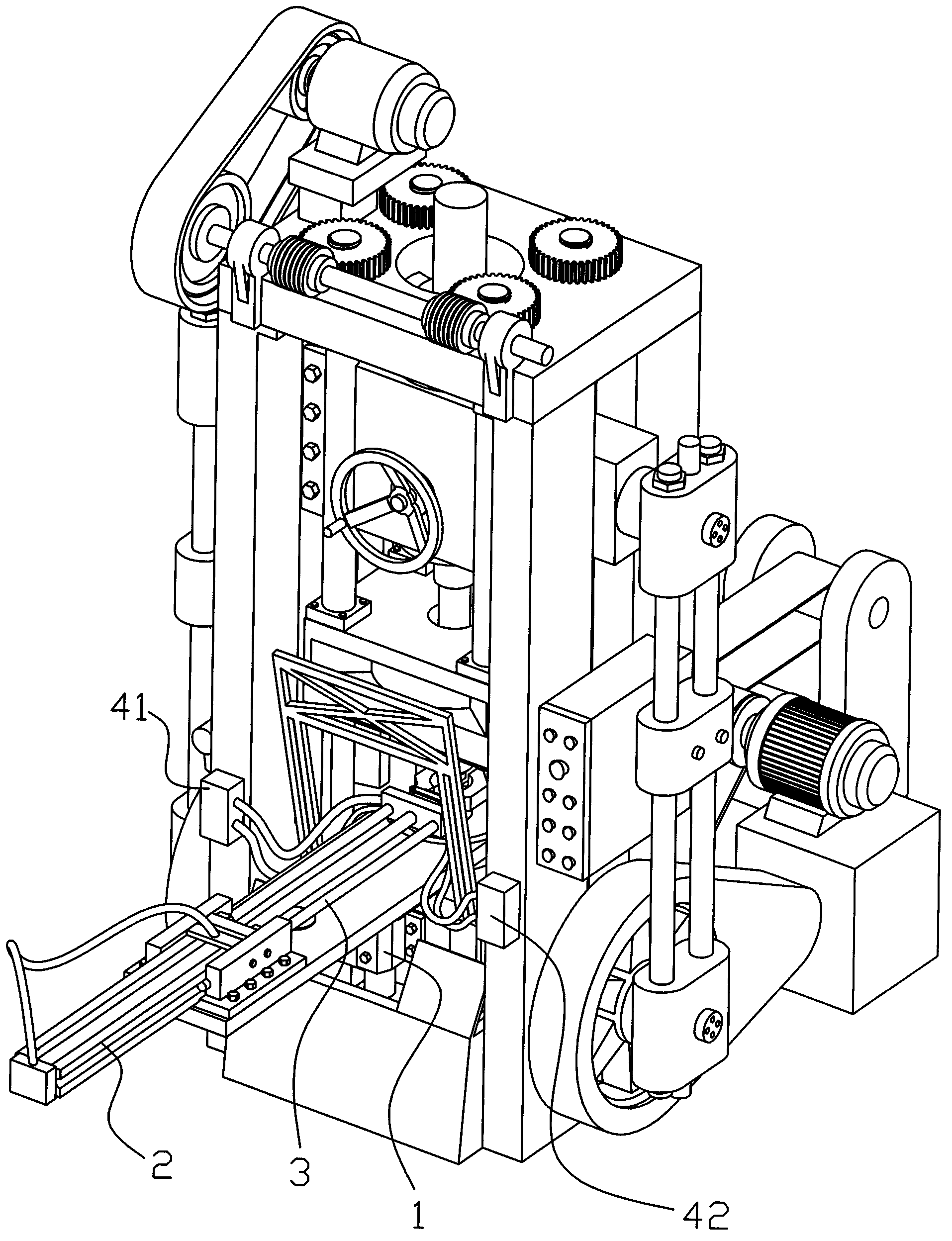

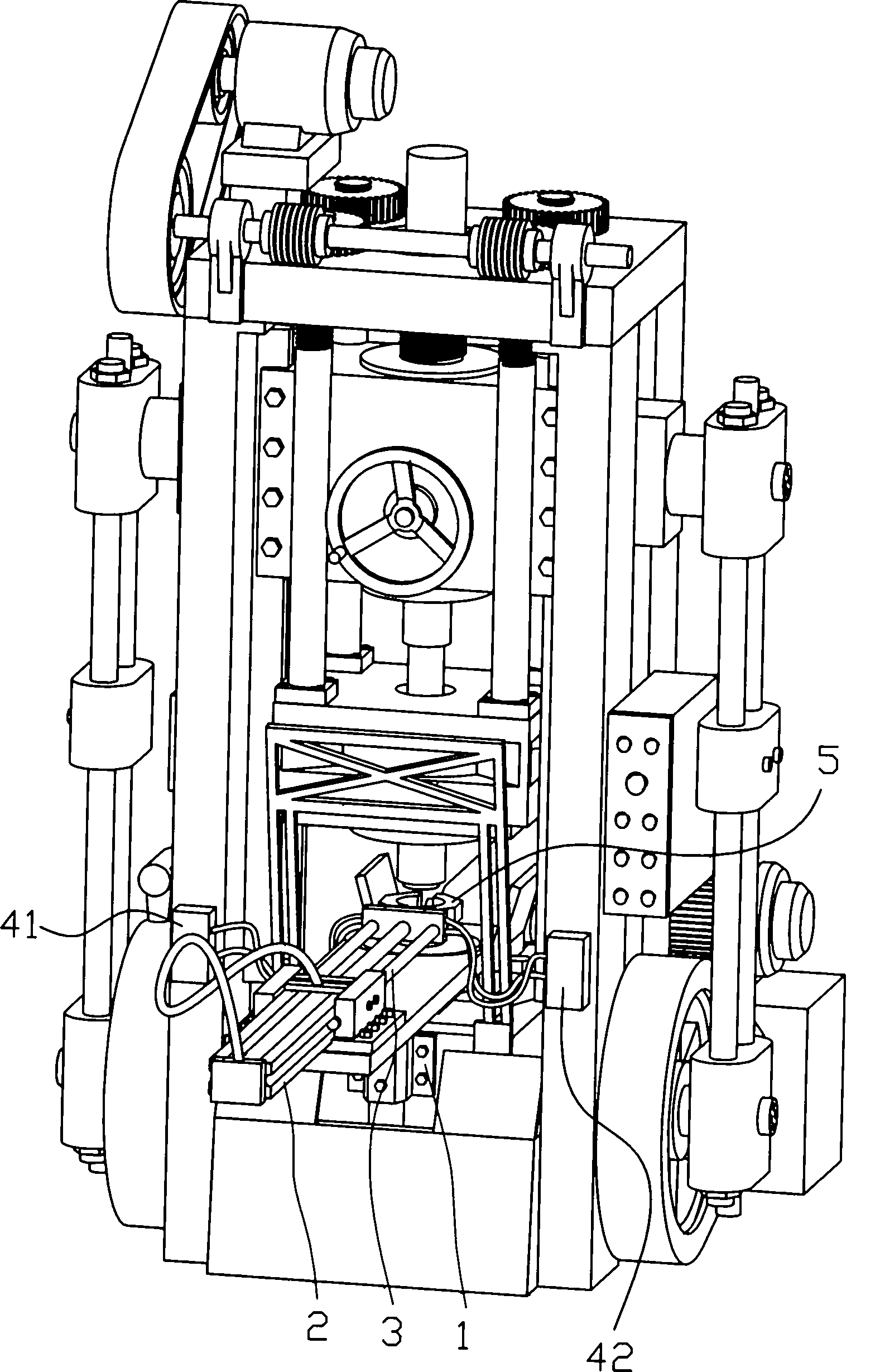

[0015] Such as Figure 1 to Figure 4 As shown, the automatic feeding device of the stamping machine tool in this embodiment includes a frame 1 horizontally installed on the side of the stamping machine tool work platform, the table on the frame 1 is on the same working plane as the stamping machine tool work platform, and the frame is provided with Slide rail 2, slide rail 2 are provided with the push rod 3 that cooperates with slide rail 2, and the front end of push rod 3 is provided with manipulator 5, also comprises the driver 41 that connects and controls push rod 3, and connects and controls manipulator 5 The driver 42; the slide rail 2, the push rod 3, the drivers 41, 42 and the manipulator 5 together form a push module, the driver 41 controls and drives the push rod 3 to reciprocate on the slide rail 2; the driver 42 controls and drives...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com