A hidden frame curtain wall installation structure

A technology for installing structures and curtain walls, applied to walls, building components, building structures, etc., can solve problems such as glass falling off, achieve good reliability, good temperature insulation effect, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

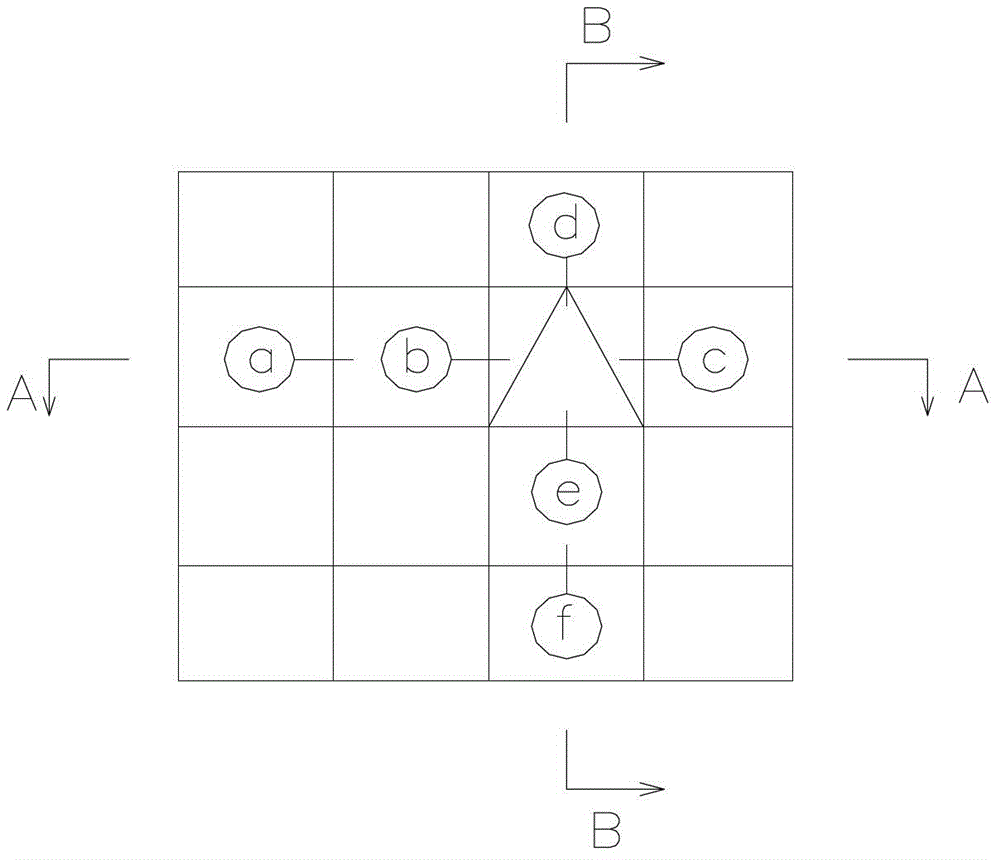

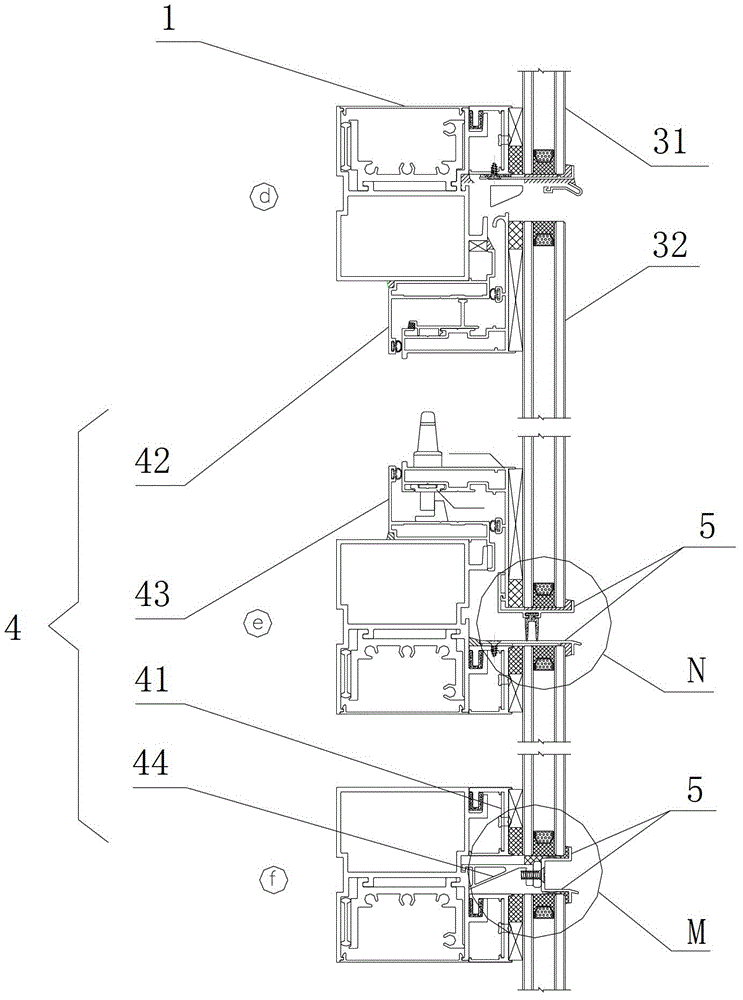

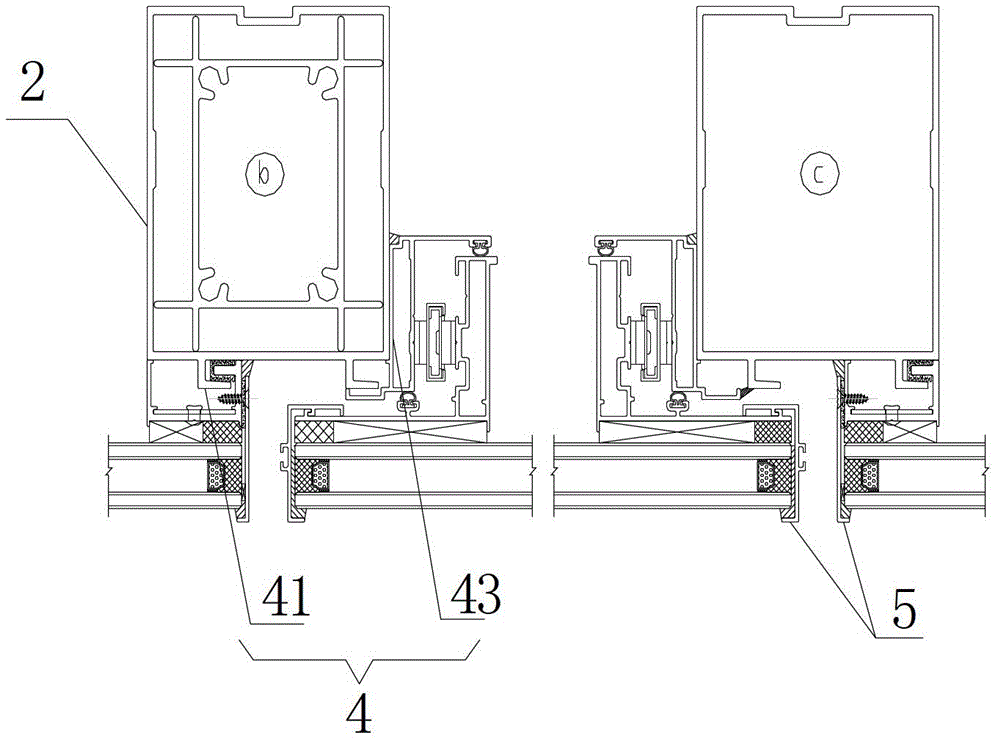

[0028] In order to further illustrate the essence of the present invention, the specific embodiments of the present invention are described as follows in conjunction with the accompanying drawings.

[0029] Such as Figure 1-Figure 3 As shown, a hidden frame curtain wall installation structure includes: a beam 1, a column 2, an adjacent panel 3, and a connecting piece 4 for installing the adjacent panel 3 on the beam 1 or column 2; In the gap between the panels 3 there is at least one rib structure 5 which is fixedly connected with the connector 4 and blocks the outer edges of the adjacent panels 3 . In this embodiment, preferably, the rib structure 5 is fixed on the connecting member 4 by buckling, and an adhesive is provided between the rib structure 5 and the panel 3 . In particular, in order to prevent rainwater from washing away the dirt in the gap and dripping on the surface of the panel 3 , a rain poncho is provided on the transverse rib structure 5 . In other impleme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com