Venturi tube for steam purge

A venturi tube and fuel steam technology, applied in electrical control, charging system, adding non-fuel substances to fuel, etc., can solve the problems of lower performance of full throttle opening, increase of air volume, and lower engine performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

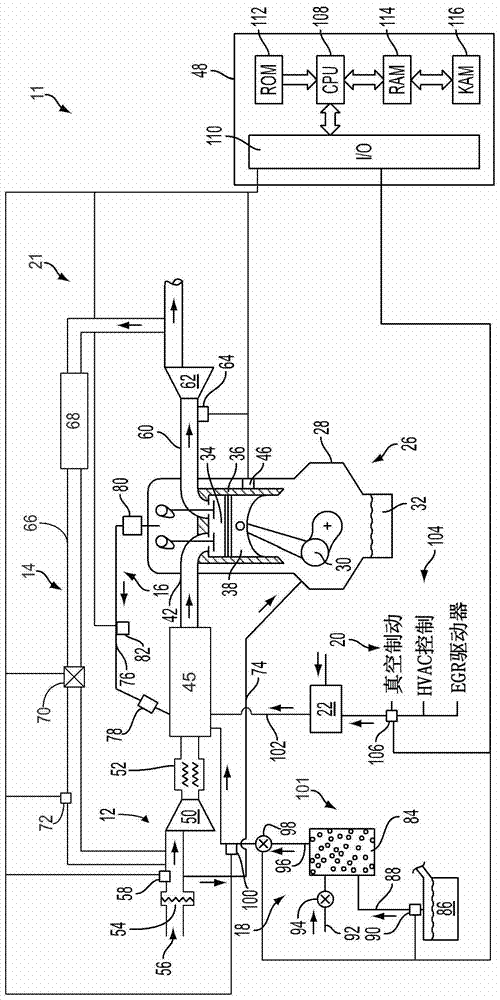

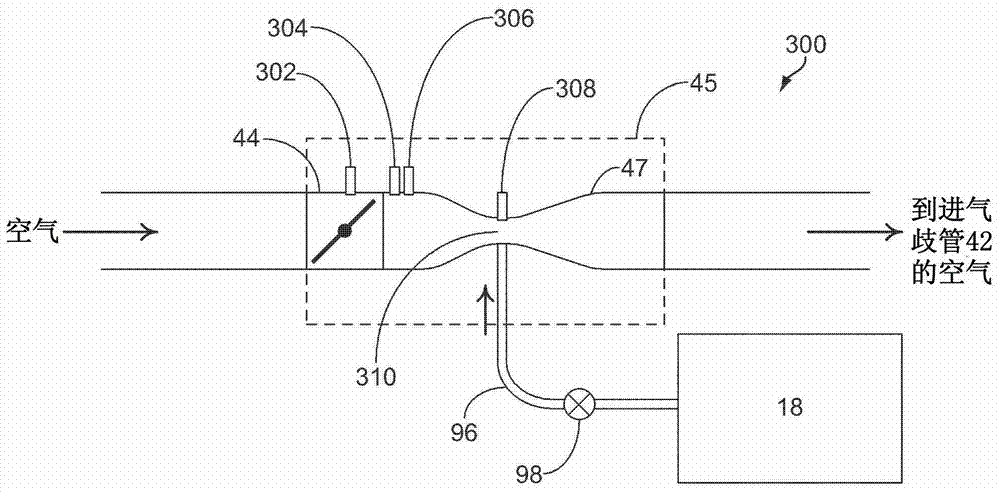

[0027] The following description relates to systems and methods for operating an engine with a fuel vapor purge system, such as figure 1 with figure 2 system shown. Such as Figure 3 to Figure 5 As shown, a venturi or aspirator can be placed in the intake system of the engine adjacent to the throttle, and a fuel vapor purge system can be connected to the venturi so that it can be used during a fuel purge event the resulting vacuum. Such as Figure 6 to Figure 7 As shown, various methods may be used to purge fuel from the fuel vapor purge system using the vacuum created by the venturi. Also, in response to engine operating conditions such as Figure 8 to Figure 11 The throttle shown adjusts to meet torque demand while still providing vacuum to the fuel vapor purge system.

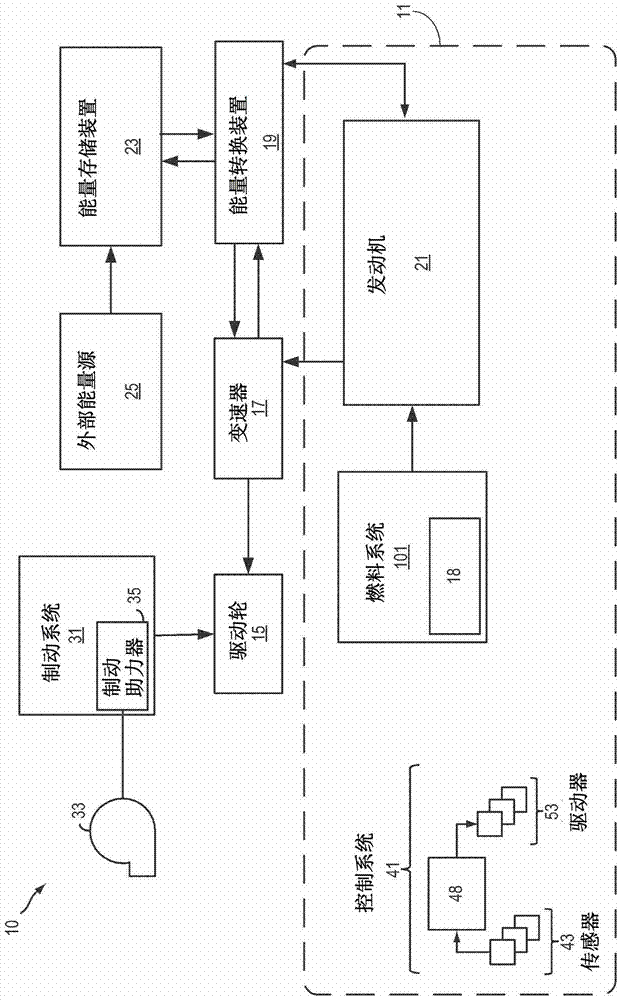

[0028] now refer to figure 1 , which schematically shows an example vehicle with an engine. In some examples, such as figure 1 As shown, the vehicle is a hybrid electric vehicle (HEV) and may inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com