Straight tube-shaped light-emitting diode (LED) lamp

A technology of LED lamps and straight tubes, applied in lighting devices, cooling/heating devices of lighting devices, light sources, etc., can solve the problems of poor heat dissipation of straight tube lamps and complicated manufacturing processes, and achieve simple manufacturing processes and extended The effect of improving the service life and improving the efficiency of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

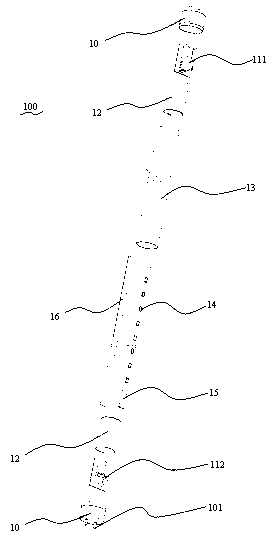

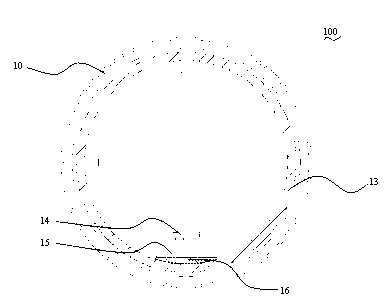

[0021] refer to figure 1 as shown, figure 1 As a three-dimensional exploded view of this specific embodiment, the LED lamp 100 of the present invention includes: a lamp holder 10, a power supply 11, a straight tube lampshade 13, and an LED lighting module 14, wherein the lamp holder 10 is fastened to both ends of the straight tube lampshade 13, specifically , an annular groove (not shown) corresponding to the diameter of the straight tube lampshade 13 can be provided inside the lamp cap 10, and the straight tube lampshade 13 protrudes into the annular groove so as to be fixedly connected with the lamp cap 10, and at the same time In order to make the connection between the lamp cap 10 and the straight tube lampshade 13 more firm, the lamp cap 10 and the straight tube lampshade 13 are bonded together with an adhesive, and the adhesive can be silica gel.

[0022] An electric contact 101 protrudes from the lamp cap 10 , and the power supply 11 is electrically connected to the la...

Embodiment 2

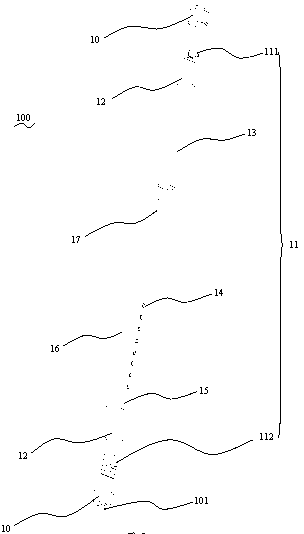

[0030] refer to image 3 as shown, image 3 It is a three-dimensional exploded view of this specific embodiment, and the general idea of the design of this specific embodiment is generally the same as that of Embodiment 1. The differences between this embodiment and Embodiment 1 are mainly introduced now. The difference between this embodiment and the first embodiment is that the LED lamp 100 further includes a metal foil plate 17 located on the inner wall of the straight tube lampshade 13 , and the substrate 15 carrying the LED light emitting module 14 is located on the metal foil plate 17 . Thus, the LED light-emitting module 14, the substrate 15, and the metal foil plate 17 form a layered structure. Specifically, the base plate 15 and the metal foil plate 17 can be fixed together by a heat-conducting glue 16, and the heat-conducting glue 16 can be any material with heat conduction and fixing functions, such as a heat-conducting double-sided adhesive or a heat-conducting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com